Freeze drying also known as lyophilization, involves freezing water and removing it from a sample through sublimation. It is widely used in the pharmaceutical and biological industries to preserve thermolabile substances. In this article, Read the Principles, Construction, Working of Freeze Dryers, Advantages and Disadvantages.

Principle of Freeze Dryer:

Freeze drying is also known as lyophilization. Lyophilization s carried out using a simple principle of physics, called sublimation. Sublimation, where water transitions directly from a solid-state (ice) to a vapor state without passing through the liquid phase. This sublimation of water can occur at pressures and temperatures below the triple point of water, which is 0.0098°C and 0.533 kilopascals by applying a vacuum. hence it is well suited for drying thermolabile compounds.

Construction of Freeze Dryer:

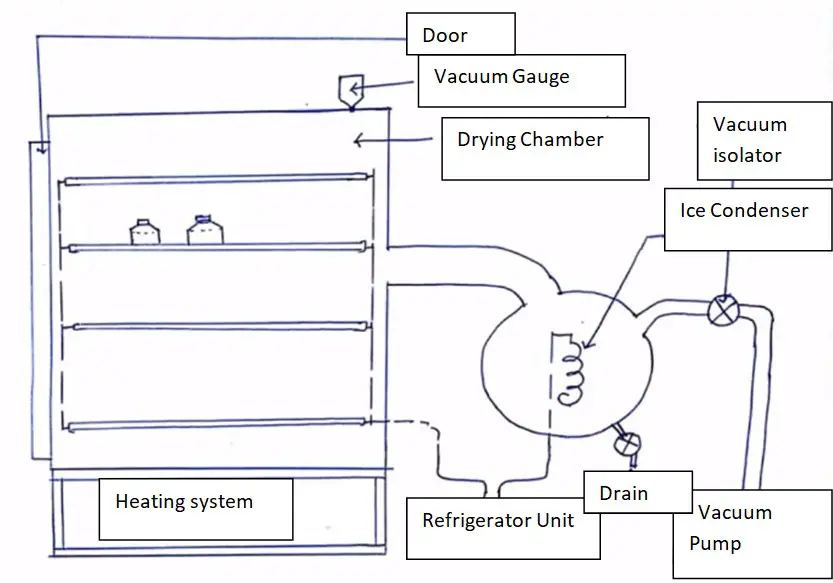

Freeze dryers are of three types: manifold freeze dryers, rotary freeze dryers, and tray-style freeze dryers. Their components are as follows:

- A vacuum pump to reduce the ambient gas pressure

- A condenser that removes moisture through condensation on a surface cooled to -20 to -80 °C.

- A freeze dryer includes a vacuum chamber where products to be dried are placed on shelves.

- A vacuum pump, refrigeration unit, and associated controls are connected to the vacuum chamber to allow the drying process.

The distance between the subliming surface and condenser must be less than the mean path of the molecules.

The temperature of the condenser must be much lower than the evaporated surface of the frozen substance (To maintain this condition condenser surface must be cleaned repeatedly)

Working of Freeze Dryer:

The process begins by freezing the sample and placing it under a vacuum, allowing the frozen water to change directly from solid to vapor without passing through the liquid phase. This sublimation of frozen material occurs at low temperature and pressure conditions below the triple point of the liquid. The freeze-drying process takes place in multiple stages: sample preparation, freezing, primary drying, secondary drying, and packing. Read all the stages process below:

Pretreatment:

Pretreatment is the important step where the solution is pre-concentrated under normal vacuum tray drying. This reduces the actual drying time by 8 to 10 times. It also stabilizes reactive products before freezing, increases surface area, and reduces the concentration of high vapor-pressure solvents.

Freezing:

In this stage samples should be packed in vials, ampoules, or bottles. It is kept on cold shelves (About -50°C). During this stage, the cabinet is maintained at a low temperature and pressure.

Primary Drying:

Primary drying involves the removal of ice formed during the freezing stage through sublimation under a vacuum and at low temperatures. Primary drying occurs at pressures of 104 to 109 atmospheres and a product temperature of -45 to -20 °C.

Secondary Drying:

Secondary drying is the final step in freeze drying. It involves desorbing most of the remaining water from the dried product by raising the temperature. At this stage, pressure is also lowered to remove water.

Packing:

During this stage vacuum is replaced by an inert gas, and the bottle and vials are closed.

Related: Vacuum Dryer

Advantages of Freeze Dryer

Freeze drying has the following advantages as below:

- Freeze-drying preserves the original characteristics, flavors, and aromas of the product.

- Thermolabile materials can be dried.

- Freez drying help in extends the shelf life of the product by removing water and inhibiting microbial growth.

- Loss of volatile materials is less.

- Freeze-dried products can be easily rehydrated by getting the same properties as before.

- Freeze drying can be applied to various materials, including food products, pharmaceuticals, biological samples, and chemicals.

Disadvantages:

Freeze drying has the following Disadvantages as below:

- Freeze-drying is expensive process.

- Freeze drying is a time-consuming process compared to other drying methods.

- The product is prone to oxidation due to high porosity and large surface area.

Applications:

Freeze drying has the following Disadvantages as below:

- Freeze drying is commonly used to preserve food products, like; fruits, vegetables, coffee, and dairy.

- Many pharmaceutical products, including vaccines, antibiotics, and biopharmaceuticals, are freeze-dried to enhance stability and extend shelf life.

- Freeze drying is used in biotechnology laboratories to preserve microorganisms, enzymes, cell cultures, and other biological samples.

Related: Spray Dryer