The Sigma Blade Mixer is one of the most popular mixers for blending and kneading materials with high viscosity. It is a double-arm kneader mixer used in handling high-viscosity materials.

Principle behind the Sigma Blade Mixer

The principle involved in these mixers, which handle highly viscous materials, depends on shearing and convecting generated by interlocking sigma-shaped blades. This action induces both lateral and transverse motion of the material.

Construction of the Sigma Blade Mixer

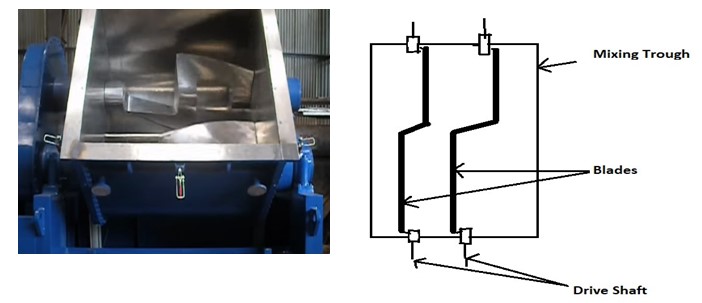

The mixer consists of two horizontally fitted mixing blades in each trough of the bowl. These blades are called sigma blade mixers due to their design match to the Greek letter sigma (Σ). The clearance between the blades and the vessel walls is kept as low as 2 mm, resulting in high shear within the material. Heavy-duty drive systems, including motors, gearboxes, couplings, and gears, rotate the blades. The top speed of the Sigma mixer is generally limited to 60 to 70 meters/min. To maintain the required temperature, the mixer trough jacket circulates hot or cold media. Discharging the material from the mixer container can be achieved by tilting the container, using the bottom discharge valve, or using an extruder/screw located between the two trough compartments.

Working of Sigma Blade Mixture

The mixing process begins by loading powders through the top of the trough, filling approximately 40% to 65% of the mixer’s total capacity.

Working: Powders are introduced from the top of the trough. The body is covered because considerable dust may be evolved during dry blending and granulating solution may evaporate during wet granulation.

In the Sigma Blade Mixer, the fixed-speed drive facilitates the rotation of the Sigma blades. The blades are designed to move at different speeds, with one blade typically rotating at about twice the speed of the other. This speed differential creates a lateral pulling effect on the material being mixed.

The Sigma blades in the mixer rotate in a manner that causes them to turn toward each other, helping in the movement of powders from the sides toward the center of the bowl. As the material progresses, it flows from the top to the bottom over the blade’s edge, where it is sheared between the blades and the trough’s wall. This combined action of cascading (convective) and shearing enables efficient mixing. Additionally, the presence of perforated blades aids in breaking down lumps and aggregates during the mixing process.

Thus high shear forces are set up. The final stage of the mix represents an equilibrium state. The operating conditions of a given mixer can be marked affect the steady state and thus the quality of the mixing. By means of a rack-and-pinion drive the bowl is tilted to empty the blend.

Discharging the material from the mixer container can be achieved by tilting the container, using the bottom discharge valve, or using an extruder/screw located between the two trough compartments. Sigma Blade Mixer produces a homogeneous mixture that typically takes between 12 to 30 minutes.

Related: Ribbon Blender

Advantages:

- The Sigma blade mixer ensures minimal dead spots during mixing operations, resulting in the production of high-quality materials.

- It is the perfect choice for mixing and kneading highly viscous masses and sticky products, used for a wide range of applications.

- These mixers and their variants can handle highly viscous materials, with viscosities of up to 10 million centipoises.

- The design of perforated blades makes the mixer suitable for breaking lumps and aggregates, leading to smooth and consistent mixing.

- By sealing the trough chamber and maintaining low temperatures, the Sigma blade mixer prevents losses such as volatile solvent evaporation during mixing.

Disadvantages:

- Sigma blades consume relatively high amounts of power compared to other types of mixers.

- Installing a Sigma blade mixer requires a larger space.

- Proper adjustments of blade speed are necessary to ensure efficient mixing.

- Efforts should be made to minimize the presence of dead spots within the mixing tank.

Applications

- It is used in the preparation of Emulsions, Syrups, and Ointments.

- Sigma blade mixers play a crucial role in the wet granulation process for producing tablets, capsules, and pill masses.

- This versatile mixer is best to use in both solid-liquid and solid-solid mixing.

- It is also useful for mixing Pasty, Sticky, and Gritty Slurries.

- Other applications include the mixing of adhesives, chemicals, chewing gum, food, hot melts, inks, pigment products, soaps and detergents, and sugar pastes.

FAQs on Sigma Blade Blender

Ans: The Sigma Blade Mixer is used for mixing and kneading high-viscosity materials.

Ans: The Sigma Blade works by generating shearing forces through interlocking sigma-shaped blades, resulting in lateral and transverse motion of the material.

Ans: Advantages of using a Sigma Blade Mixer include minimal dead spots during mixing, suitability for high-viscosity materials, the ability to handle up to 10 million centipoises of viscosity, and the inclusion of perforated blades for breaking lumps and aggregates.

Ans: Disadvantages of using a Sigma Blade Mixer include high power consumption compared to other mixers, and larger space requirement for installation.

Ans: A Sigma Blade can mix and knead a wide range of materials, including high-viscosity masses, sticky products, slurries, adhesives, chemicals, food, and confectionery products.

Ans: The shearing action in a Sigma Blade is achieved through the inter-meshing sigma-shaped blades, which pull, shear, compress, knead, and fold the material against the walls of the mixer trough.

Ans: The Sigma Blade Mixer consists of two horizontally fitted mixing blades in each trough of the bowl, designed in the shape of the Greek letter sigma (Σ). The mixer also features a jacket for temperature control, a heavy-duty drive system, and options for discharge through tilting, a bottom valve, or extruder/screw.

Ans: A homogeneous mixture can be obtained within 12 to 30 minutes of mixing.

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].