A spray dryer is an instrument used to dry a liquid feed, for example; solution, suspension, or paste, into dried particles by spraying the feed into a hot drying medium. In this article learn about their Principle, Construction, Working, Advantages, and Disadvantages.

Principle of Spray Dryer:

The principle of spray drying involves transforming a liquid feed into a spray of small droplets and exposing these droplets to hot air. This phenomenon leads to the evaporation of the solvent, and dried particles separate out.

Construction of Spray Dryer:

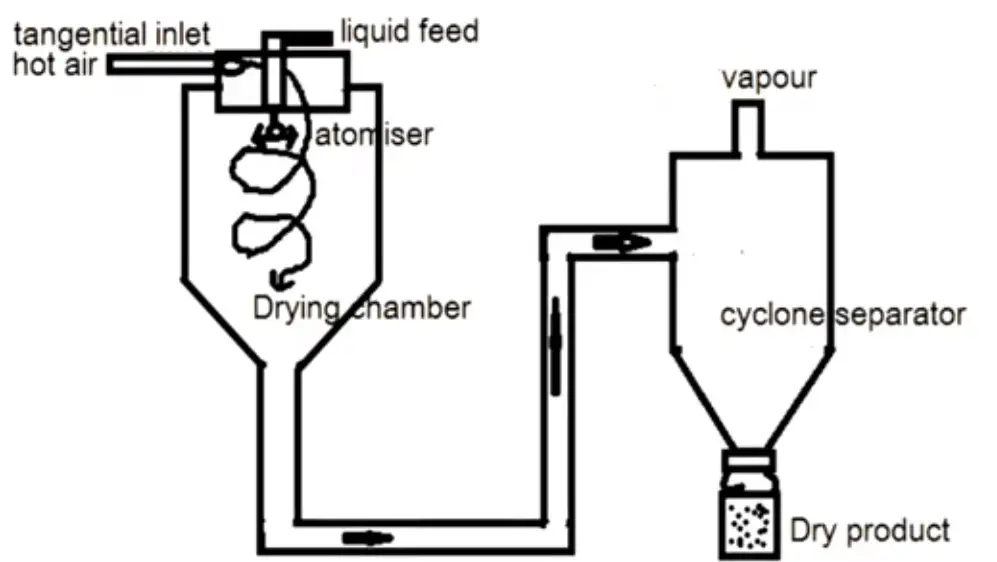

A spray dryer consists of several components, including a feed pump, atomizer, air heating unit, air dispenser, and drying chamber (with a diameter ranging from 2.5 to 9.0 meters and a height of 25 meters or more), as well as exhaust air cleansing and powder recovery/separator. The atomizer is a type of spray disk, that has a diameter of about 300 millimeters and rotates at a speed of 3,000 to 50,000 RPM. The liquid to be dried is atomized into small droplets, which move into a moving stream of hot gas.

Working of Spray Dryer:

In a spray dryer, a liquid feed is sprayed through a nozzle into a hot vapor stream. The liquid quickly vaporizes, and the solids or particles are collected in a drum or cyclone. The three main stages in a spray drying process are atomization, spray-air mixing and moisture evaporation, and separation of the dry product from the exit air. The final product obtained after drying in a spray dryer depends on the design and operation of the dryer, as well as the physicochemical properties of the feed.

Related: Drum Dryer

Steps involve in Spray Dryer:

Advantages of Spray Drying:

- Small droplets give a large Surface area for rapid and efficient drying.

- Heat-sensitive and oxidizable materials.

- Can be designed for drying under sterile conditions.

- Dried particle has uniform size and shape.

- Good flow property can be easily compressed.

- Used for coating and encapsulation of solids and liquids.

- Labor cost is low, drying in a single operation.

Disadvantages of Spray Drying:

- Bulky and expensive to install.

- Challenging to clean after use.

- Low thermal efficiency with significant heat loss during operation.

- Not suitable for drying solid materials.

- Potential for product degradation or fire hazard due to product deposit on the drying chamber.

Pharmaceutical Uses of Spray Dryer:

The application of the spray drier is as follow:

- Drying pharmaceutical products like penicillin, blood products, enzymes, and vaccines.

- Production of excipients and co-processed excipients to enhance flowability, compatibility, and tablet disintegration.

- Improving drug compressibility and reducing capping tendencies in crystals.

- Preparation of matrix microcapsules for controlled drug release formulations.

- Enhancing solubility and dissolution rates of poorly soluble drugs through the formation of pharmaceutical complexes or solid dispersions, thereby increasing bioavailability.

- Production of dry powder formulations, dry powder aerosols, and thermolabile materials.

Variants of Spray Dryer:

- Sterile spray dryer for pharmaceutical applications.

- Closed spray dryer for solvent recovery.

- Oxygen-free spray dryer for specific environments.

- Dual-purpose equipment

Types of Spray Dryers:

Conventional Spray Dryer: This is the most common type of dryer, where the liquid feed is atomized into small droplets and dried by hot air.

Centrifugal Spray Dryer: In this type, the liquid feed is atomized using a spinning disk or a high-speed rotating wheel, providing more control over droplet size and distribution.

Fluidized Bed Spray Dryer: This type combines spray drying with fluidized bed technology. The liquid feed is sprayed onto fluidized particles, and drying occurs as the particles move through the drying chamber.

Rotary Atomizer Spray Dryer: It uses a rotary atomizer to atomize the liquid feed into fine droplets, offering precise control over droplet size and high drying efficiency.

Nozzle Spray Dryer: This type uses nozzles to spray the liquid feed into the drying chamber, offering flexibility in droplet size control.

Conclusion:

Spray drying is a widely used industrial process for transforming liquid feeds into dried particles. So it becomes important to choose the right choice of equipment for easy and fast processing.