1.0 Purpose: To describe the procedure for tub handling of prefilled syringes of filling machine.

2.0 Aim: This Standard Operating Procedure is applicable for tub handling of prefilled syringes of filling machine at Production.

3.0 Responsibility:

3.1 Officer Production

3.2 Head Production

4.0 Safety considerations:

4.1 Handle the tubs with care while transferring them from one place to another place.

4.2 Ensure the tubs received from the warehouse are in good condition without any damage.

4.3 Disinfect the tubs (outer surface) taken out from PP boxes with filtered IPA 70% v/v and transfer them through the dynamic pass box into the respective areas.

4.4 Always open the tub under the LAF unit.

5.0 Preparation of solutions:

5.1 Prepare IPA 70% v/v.

6.0 Procedure:

6.1 Receive the QC-approved boxes of prefilled syringes from the warehouse. Keep them in the approved primary packing material store in the production area before use in filling.

6.2 The boxes are transferred on a cleaned ‘SS’ trolley with the status label.

6.3 Open the boxes with the help of a box cutter.

6.4 Disinfect the packed tubs by spraying filtered 70 % IPA and transfer through the Dynamic pass box to the Material Airlock.

6.5 Tear off the approved label from the empty box and transfer it to the waste collection area through the Static pass box for destruction.

6.6 The tubs are transferred onto the clean SS Trolley from the Dynamic pass box to the Loading Area.

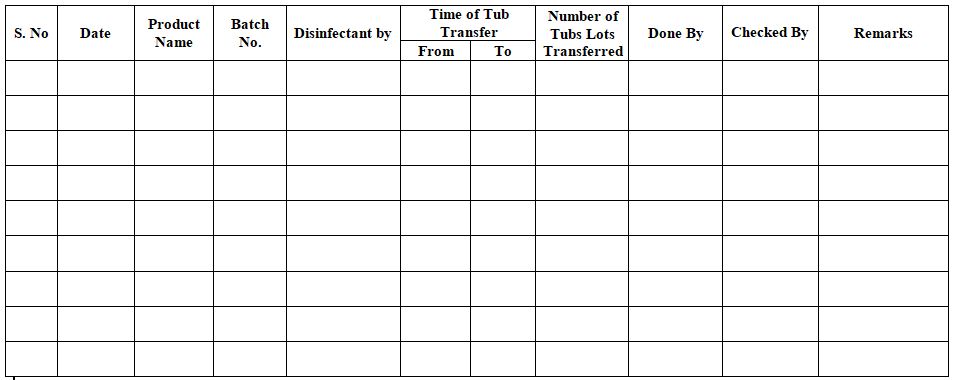

6.7 Disinfect the packed tubs by spraying filtered 70 % IPA and transfer through the Dynamic pass box from the Loading Area to Buffer Zone and record the tub transfer detail in Annexure 1.

6.8 Remove the tubs from the poly bag and load them in the Mobile transfer trolley.

6.9 Transfer the Mobile LAF trolley to the PFS filling Room.

6.10 The mobile transfer trolley is transferred and placed near the filling machine and each tub is transferred directly from the mobile trolley to the tub loading area of the PFS filling machine before filling.

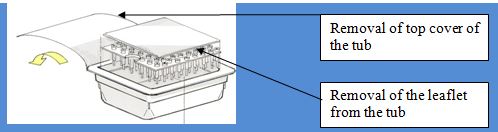

6.11 Remove the cover of the tub only under Filling LAF in one go by lifting and dragging the cover diagonally to the corner of the tub with sterile teethed forceps (SS 316).

6.12 Remove the leaflet from the tub using sterile forceps and keep it under LAF. Then load the tub.

6.13 After completion of filling, each tub is again covered with a leaflet.

6.14 The filled and covered tubs are placed into the poly bag and sent through DPB on a cleaned ‘SS’ trolley.

6.15 Filled tubs are transferred in a lot.

6.16 The filled pre-filled syringe tubs which are transferred are sealed with tape.

6.18 The filled tubs with the poly bag are placed in the cleaned & labeled crates and are transferred in the wide corridor to the warehouse through the Dynamic pass box on a cleaned SS trolley.

6.19 After completion of tub transfer give Semi Packed Transfer Note to the warehouse.

6.20 The tubs are stored in the cold storage room of the warehouse until the packing process is initiated.

6.21 In case of online packing, transfer the filled tubs to the production Cold room through the corridor.

6.22 Before initiation of packing, fill the semi Packed material request as per the “issuance and transfer to warehouse” SOP.

6.23 Receive the tubs from the warehouse through the Dynamic pass box on a cleaned SS trolley and transfer them to the cold room of the production area.

6.24 The tubs with the pre-filled syringes are taken into the PFS visual inspection room in the lot wise where the automatic inspection of PFS is carried out.

6.25 After completion of the visual inspection the prefilled syringes are sent for the further online packing process.

6.26 The empty tubs from the visual inspection area are sent to the waste collection area through the Static pass box for destruction.

7.0 Abbreviations:

SOP: Standard Operating Procedure

SS: Stainless Steel

QA: Quality Assurance

IPA: Iso Propyl Alcohol

LAF: Laminar Air Flow

v/v: volume by volume

PFS: Pre-Filled Syringe

%: Percent

PP: Polypropylene

Annexure-1

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].