Air changes in pharmaceutical cleanrooms play a significant role in maintaining the cleanroom quality as per ISO CleanRoom Classification through the HVAC system. Air change per hour is the number of total replacements of any room air in one hour. if the supply of air by the HVAC system in one houres is equal to the volume of the room then it will be one air change per hour. room having 100 air changes per hour will have 100 times the air supply than the volume of the room. FDA recommends maintaining a minimum of 20 air changes per hour in cleanrooms.

How to calculate the Air change per hour (ACPH)

First, calculate the air velocity in feet per minute below the HEPA filter.. it is determined at the four corners and the center of the filter and the mean of the five readings is determined.

ACPH Calculation steps:

Step 1:

V= (V1+V2+V3+V4+V5)/5

V is the velocity observed at each point.

Step 2:

Now calculate the area of the filter by multiplying the length and width of the filter in the feet.

A= LxW

L- Length of HEPA filter, W- width of the HEPA Filter

Steps 3:

Calculate the total air volume per minute supplied in the cleanroom by the following formula: Q= AxV

whereas, A= Area of HEPA Filter in square feet

V= Average air velocity in feet per minute

Steps 4:

Calculate the total room volume by multiplying the length, width, and height of the room in feet.

Volume- LxWxH

Steps 5:

Calculate the air change per hour using the following formula:

Air change per hour (ACPH) = Q x 60/volume

The requirement of the number of ACPH for any room depends on the class of the room, the number of personnel working in the area, and the frequency of access to the room. the cleanness of any cleanroom is maintained by the air change per hour.

The critical area where more dust or particle are generated like granulation, compression, and coating required more air change per hour, so area dust is to be removed within short periods, hence more air change per hour is required at the same time.

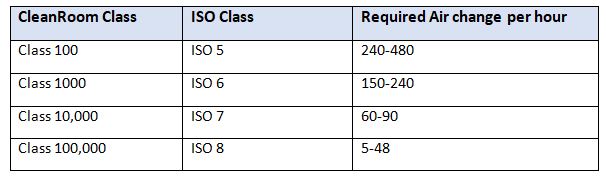

The Table on Air change per hour (ACPH) in different classes of a classified area.

As above in Class 100 more air change per hour is required as compared to class 100,000

The Importance of ACPH

The following factors make the number of air changes per hour significant.

- To ensure suitable ventilation.

- To remove dust, smoke, and fumes from space, a room, or a structure.

- To remove the area of gases like carbon dioxide.

- To continue having a clean room by removing undesirable particles.

- Removing viable count adheres to the non-viable particle in order to maintain clean room status

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].