The method used for the removal of particulate matter from air, gas, or water stream with the help of vortex rather than filters is known as cyclonic separation. Gravity and rotational effects are helpful in the separation of solid mixtures from those of fluids. in this article, we will discuss Cyclone Separator: Principle, Construction, Working, Application, and their Variants.

Cyclone Separator Principle:

Cyclone separator is a type of sedimentation technique that works on the principle of centrifugal force rather than gravitational force. Thus, based on the fluid velocity, a cyclone enables the separation of all the particles or only the coarse particles can be removed, leaving behind the particles which are then carried away by the fluid.

Cyclone Separator Construction:

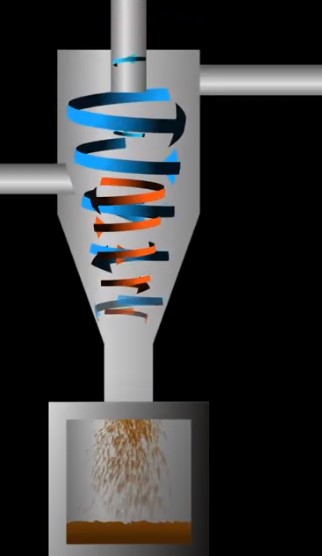

Comprising a cylindrical vessel with a conical base, the cyclone separator is designed to optimize its functionality. The upper section of the vessel is equipped with a tangential inlet and a fluid outlet, while the base is fitted with a solid outlet for particle discharge.

Cyclone Separator Working:

To initiate the process, a gas suspension carrying solid particles, typically air, is introduced into the vessel with a tangential entry at an exceptionally high velocity, thereby creating a rotational motion within the system. The fluid is subsequently extracted from a central outlet located at the top. As the gas circulates within the cyclone separator, the centrifugal force comes into play, exerting its influence on the particles. This force propels the solids towards the walls, ultimately leading them to descend and collect at the conical base, ready for expulsion through the solids outlet.

Applications:

The applications of cyclone separators extend to the separation of solid suspensions in gas, particularly air. Additionally, these separators can also be utilized for liquid suspensions containing solid particles. By harnessing the power of centrifugal force, cyclone separators provide an effective means of achieving particle separation and enhancing the efficiency of various processes.

In pharmaceuticals, it employs cyclones to segregate fine particles from larger granules. These cyclones play an important role in tablet compression by extracting excess powder, ensuring it is removed prior to reaching the central extraction system.

Related: Rapid mixture granulator(RMG)

Advantages and Disadvantages of Cyclone Separators

Advantages:

- It is Highly Efficiency

- Cost-Effectiveness

- Compact and Space-Saving

- Versatile Applications

Disadvantages:

- Cyclone separators require adequate space for installation due to their design.

- Required more energy input.

- Required a Large amount of air to be introduced.

Cyclone Separator Variants

The cyclone separator, a versatile apparatus, finds utility not only in gas-solid separation but also in the separation of solid particles suspended in a liquid medium. This variant, known as a wet or liquid cyclone, capitalizes on the contrasting densities of the solid and liquid particles involved. Notably, when dealing with a liquid suspension, the task becomes more intricate due to the heightened viscosity of water in comparison to air.

To achieve effective separation in such cases, a greater centrifugal force must be exerted. One method to amplify this force involves reducing the diameter of the vessel, thereby intensifying the effects of centrifugation. As the cyclone separator operates, coarse particles, propelled outward by the formidable centrifugal force, the journey toward the vessel walls and eventually gather at its base. Concurrently, the lighter particles, alongside the liquid medium, make their escape through the outlet positioned atop the vessel. This interplay of forces and dynamics showcases the efficient functionality of the cyclone separator in the context of liquid-solid particle separation.

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].