Learn About Standard Operating procedure on the Depyrogenation method and washing of Test tubes for BET.

1.0 Object: 1.1 To lay down the procedure for the Depyrogenation method and washing of test tubes for BET.

2.0 Scop: 2.1 This SOP applies to carry out the procedure of the Depyrogenation method and washing of test tubes for BET in a microbiology laboratory

3.0 Responsibility: 3.1 Executive Microbiologist/ Microbiologist/

3.1.1 Preparation of SOP

3.1.2 Training for new joiners.

3.1.3 To perform an activity.

3.1.4 Keep data as per GDP

4.0 Distribution: 4.1 Master Copy- Quality Assurance Department

4.2 Control copy- Quality Control Department

5.0 Procedure:

5.1 First, wrap the head of the individual tube and then wrap a set of 20 assay tubes properly with aluminum foil to cover the whole tube.

5.2 Place the tubes in a hot air oven and operate the hot air oven. Close the door and set the temperature of the hot air oven at 250°C.

5.3 Depyrogenate the test tubes at 250°C for 1 hr. After completion, switch off the hot air oven.

5.4 When the temperature reaches 500 to 600 °C, open the door of the hot air oven and collect the tubes in a clean and dried S.S. tray.

5.5 It is recommended to use the dehydrogenated test tubes within two days. If it is not used within two days, again dehydrogenate the tubes.

5.6 After the BET test, dip the test tubes to be cleaned in 1000 ml of the beaker and add a sufficient amount of WFI.

5.7 Boil the tubes on a hot plate for 15-20 minutes to remove the gel content from the tubes.

5.8 Allow the tubes to cool at room temperature. Remove water and rinse with fresh WFI water three times.

5.9 Again, boil the tubes on a hot plate for 10 minutes and repeat step 5.7.

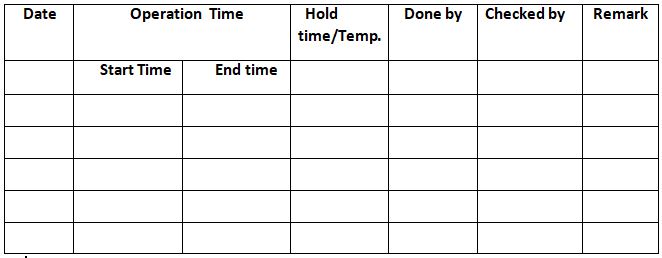

5.10 Record the details in the format mentioned in Annexure–I.

6.0 Abbreviation:

QA – Quality assurance

QC – Quality Control

SOP – Standard operating procedure

LAF – Laminar airflow

GDP – Good documentation practices

Annexure-1: Depyrogenation method and washing of Test tubes for BET

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].