The Elutriation Tank is designed to achieve size separation of particles by using the distinct densities of fine and coarse particles. So to do this elutriating tank is used to effectively separate these particles. in this article, we will discuss Elutriation Method, Principle, Working, Construction, Advantages, and Disadvantages.

Principle of the Elutriation Tank:

The elutriation process categorizes particles, moving through a rising fluid, into two distinct sizes. Within a sorting column, as the fluid rise at a specific velocity, particles with terminal velocities higher than this velocity settle at the column’s bottom, while particles with lower terminal velocities get carried to the top and transported to the next tube. Stokes’ law equation, which incorporates variables such as particle-specific gravity, fluid medium-specific gravity, particle radius, medium viscosity, terminal velocity, and gravitational acceleration, helps calculate the terminal velocities of particles descending in a fluid.

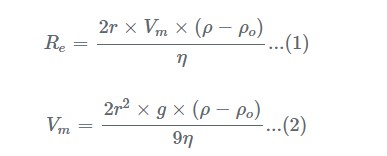

Where, ρ = specific gravity of the particle, ρo= specific gravity of the fluid medium, r= is the radius of the particle, η = viscosity of the medium, Vm = terminal velocity of the particle, and g = gravitational acceleration.

When the volumetric flow rate of the rising fluid remains constant during elutriation, the velocity of the rising fluid within the columns depends on their diameters. Columns with narrow diameters yield high fluid velocities, while wider-diameter columns result in lower fluid velocities. Coarser particles settle when the rising medium exhibits higher velocities, whereas finer particles settle when the medium’s velocities decrease. By segregating the sample into series-connected columns of increasing diameters, one can obtain various size classes of particles, with the upper size limit conforming to Stokes’ law.

Related Post: Bag Filter

Types of Elutriation Tank:

Elutriation Tank basically of two types as follows:

Single Elutriation Tank: Single Elutriation Tank uses only one tank.

Multiple Elutriation Tank: Elutriation Tank uses two or more tanks.

Working:

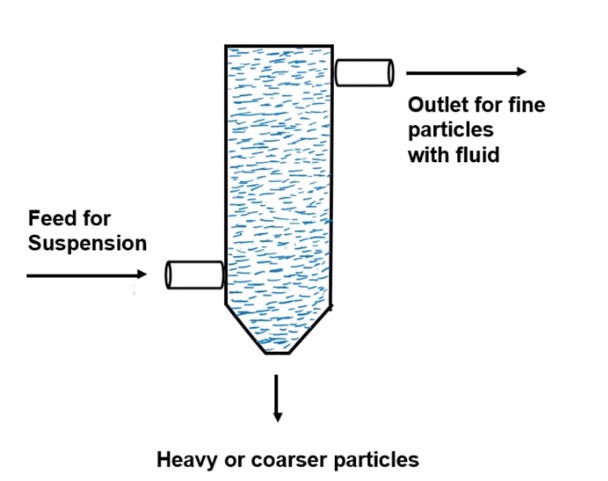

Single Elutriation Tank: The feed is introduced from the bottom then, Liquid is allowed to move in the vertical direction, whereas particles tend to settle down due to gravitational force. As discussed in the principle section, the particles with greater velocity (heavier or coarser) settle down to the bottom due to gravitational force, and are collected from the bottom Thus, by adjusting the velocity of particles fractions of different densities can be collected from the bottom. A single column is generally used to separate particles into two fractions. A lighter portion of particles may also be separated through the overflow.

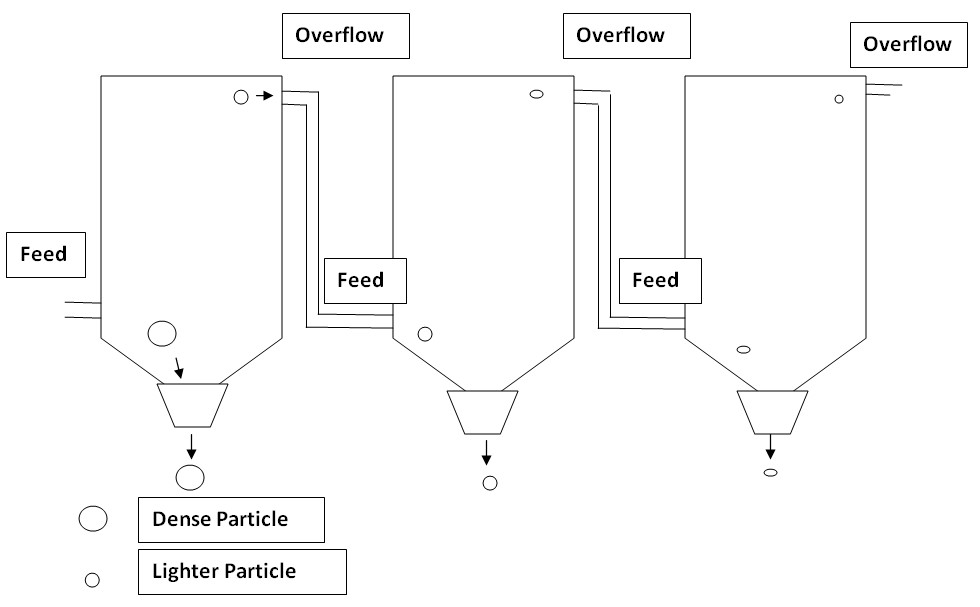

Multiple Elutriation Tank: Tanks of the different cross sections are arranged in series The feed is introduced from the bottom of the first tank The overflow of the tank is connected with a feed of another tank having more cross-sectional area and similarly third tank is filled by the overflow of the second tank The flow rate is kept constant in all tanks, but the velocity decreases when liquid moves from one tank to another because of increase in cross-sectional area Thus, coarser particles retained in first tanks whereas finer portions will be retained by next two tanks depend on their respective cross-sectional area.

Construction of the Elutriation Tank:

In a gravity-based system, the apparatus comprises a vertical column equipped with a suspension inlet near the bottom, a coarse particle outlet at the base, and a fluid overflow near the top (see the above Diagram). While a single column allows for a two-fraction separation, it’s important to note that this approach does not yield a distinct separation, as there exists a velocity gradient across the tube, causing particles of varying sizes to separate based on their distance from the wall. For multiple fractions, several tubes with increasing cross-sectional areas can be connected in series (see Above Diagram).

Fig.1: A Schematic of a Simple Elutriator

When maintaining a constant overall flow rate, the velocity diminishes in succeeding tubes as the cross-sectional area increases, resulting in the creation of multiple fractions.

Fig.2: Multi-Stage Elutriator: (1) to (3) represents fractions of decreasing particle size

Advantages of Elutriation Technique

- The elutriation process is continuous, facilitating efficient workflow.

- Depending on the desired number of fractions, an equivalent number of tubes with varying cross-sectional areas can be interconnected.

- Compared to alternative separation methods, elutriation achieves faster separation results.

- The apparatus exhibits a more compact design in comparison to sedimentation methods.

Disadvantage of Elutriation Technique

- The suspension must be diluted to avoid hindrance during settling by other particles — sometimes not possible.

- Do not give accurately sized products as screens do, because the lighter fraction of particles start moving with liquid, moving towards wall sides where the velocity of the liquid is less and then tends to settle down.

Applications of the Elutriation Tank:

Both simple and multiple elutriators are helpful in gaining the following useful application.

- Separation of insoluble solids e.g. kaolin or chalk after wet grinding.

- Used for washing out 10-45% of the solids from the incoming sludge stream of plants. Elutriate may then be recycled and utilized by the plant again.

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].