Learn about Microbiology incubators including their definitions, Working principle, Working essential components, usage, parts, different types of Incubators, advancement, Limitations, and Application.

Incubator/ Definition:

incubator is an essential device used in the microbiology section. Its insulated and enclosed design helps to control the environment. It also helps to control the temperature, humidity, and other parameters that are required for an organism’s growth. The incubator is used to grow cell cultures of both unicellular and multicellular organisms under simulated conditions.

Operating Principle of an Incubator:

The principle of Incubators is based on conditions that are required for the growth of microorganisms. The microbiological incubator helps regulate the temperature, humidity, oxygen levels, and carbon dioxide concentrations that will enhance the growth of microorganisms in the culture. The thermostat (Device for Detection of Temperature change) in an incubator ensures a consistent temperature, while other parameters like humidity and airflow are regulated through sensors and mechanisms. Some incubators, like the shaker incubator, allow for the continuous movement of cultures that is required for cell aeration and solubility studies.

Working of Incubator:

The working of the incubator involves placing the cultured organisms at the required temperature for a specific duration. For bacteria, the usual incubation temperature is 35-37°C.

Steps-wise working of incubator:

1. Make sure no previous products or materials remain inside the incubator.

2. Close the door and switch on the incubator. Heat the incubator to the specified temperature as required for a particular microorganism to grow.

3. Set the incubator’s CO2 concentration and humidity level if required by a microorganism.

4. Once all the parameters are met, the petri dish cultures are placed on the perforated shelves upside down, i.e., media uppermost. This is necessary because if the plates are incubated normally, condensation collects on the surface of the medium and prevents the formation of isolated colonies.

5. Sealed the plates with adhesive tape If culturing is required to held for several days.

6. Close the door tightly.

7. Open the door and take out the plate after the completion of the required time.

Related: Depyrogenation vs. Sterilization

Usage of Incubator:

- Bacterial growth

- Cell Growth

- Fungal Growth

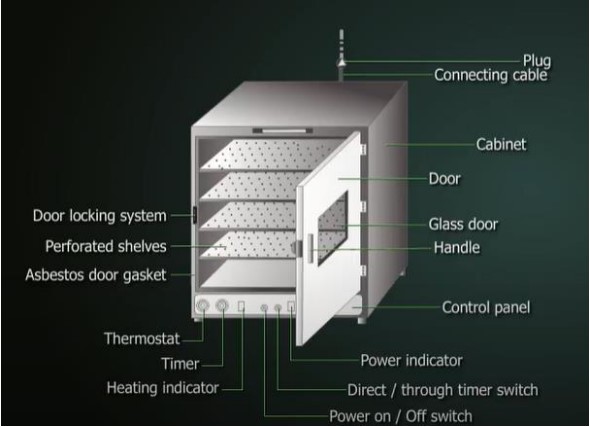

Parts of Incubator:

Image Credit: scholar.ppu.edu

1. Cabinet

The heart of an incubator is the cabinet. It is a cuboidal structure with double walls that ranges in capacity from 20 to 800 Liters. The outer shell is constructed of stainless steel while the inner one is prepared from aluminum. Situated between these two walls is a layer of glass wool, providing insulation to the incubator. This insulation minimizes heat loss and optimizes electric consumption, allowing the device to run smoothly. The inner wall is designed with inward protrusions, acting as supports for the internal shelves.

2. Door

Every incubator comes equipped with a door to seal the insulated cabinet. Along with providing insulation, the door features a glass panel, making it possible to observe the interior without disturbing internal conditions. For ease of operation, a handle is fitted on the door’s exterior.

3. Control Panel

Control Panel Located on the incubator’s outer wall, the control panel contains all switches and indicators to regulate the device’s parameters. It also includes a switch to control the incubator’s thermostat.

4. Thermostat

The thermostat is a critical component for setting the incubator’s desired temperature. Once the set temperature is reached, the thermostat then maintains that temperature consistently, unless manually changed.

5. Perforated Shelves

Perforated shelves are affixed to the incubator’s inner wall and function as the platform upon which culture media plates are placed. The perforations allow for controlled air movement within the cabinet. Some incubators feature removable shelves for easy cleaning.

6. Asbestos Door Gasket

An asbestos door gasket provides an almost airtight seal between the door and the cabinet. This seal prevents outside air from infiltrating the cabinet, thus maintaining a stable internal environment.

7. L-Shaped Thermometer

A thermometer is placed on the incubator’s top exterior wall to read temperature levels accurately. One end with a mercury bulb extends slightly into the chamber, while the other end displays the readings outside the device for easy monitoring.

8. HEPA Filters

Advanced incubators come fitted with HEPA filters to mitigate contamination due to airflow. A filter-equipped air pump creates a closed-loop system for less contaminated air circulation.

9. Humidity and Gas Control

Some incubators, especially CO2 types, come with a reservoir beneath the chamber for water storage. The water is vaporized to maintain relative humidity inside the chamber. Likewise, these incubators also have gas chambers to control the level of CO2.

Different Types of Bacteriological Incubators:

Below learn the Types of incubators along with their Descriptions, Features, and usage:

Benchtop Incubators

Description: Basic temperature-controlled and insulated devices. They are usually compact and portable, making them ideal for small labs.

Usage: Culturing of bacteria, yeasts, molds, and other microorganisms under controlled conditions.

CO2 Incubators

Description: Automatically control CO2 and humidity levels.

Use: Suitable for bacteria requiring 5-10% of CO2 concentration.

Cooled Incubators

Description: Function at temperatures below ambient levels.

Feature: Unique heating and cooling controls.

Shaker Incubators

Feature: Ability to transfer heat rapidly.

Use: Enhance growth in liquid cultures.

Portable Incubators

Description: Compact size, ideal for fieldwork.

Use: Suitable for small-scale experiments.

Anaerobic Incubators

Description: Create a sealed oxygen-free environment.

Use: It is Ideal for growing anaerobic bacteria.

Versatile Use-Case of Incubators:

Incubators have a wide array of applications in various sectors like cell culture, pharmaceutical, hematological, and biochemical studies. They can be used to grow microbial or cell cultures, maintain cultures for future use, enhance the growth rate of slow-growing organisms, and for breeding insects and hatching eggs.

Precautionary Measures:

- It’s important to avoid temperature fluctuations by minimizing the opening of the incubator’s door.

- Appropriate growth parameters should be set before placing culture plates inside.

- Regular cleaning of the incubator is a must to prevent organisms from settling.

- If using the incubator for extended periods, sterile water should be placed underneath the shelves to prevent the culture media from drying out.

Challenges with Bacteriological Incubators

Biological incubators, an important area of research, face challenges with CO2 incubators due to oxygen limitations. It’s logical to think that since human cell cultures grow in air containing 20.9% oxygen, this should be the ideal oxygen level inside an incubator. Since regular air has 20.9% oxygen, there’s no need to seal CO2 incubators from outside air.

CO2 incubators are usually kept heated to 35-37°C with 95% relative humidity and 5% CO2 levels. Microbiological incubators are mainly used for growing and storing bacterial cultures. They must maintain conditions similar to the human body: pH 7.4, 98.6°F (37°C), and over 90% relative humidity.

Related: Sterilization, Method of sterilization

References & Sources

- “The Basics of Incubator Operation and Maintenance” by Thermo Fisher Scientific

- “Types of Laboratory Incubators: CO2, BOD, Refrigerated & More” by Lab Manager

- “Incubators: Their History and Uses in Microbiology and Beyond” by American Society for Microbiology.

- https://scholar.ppu.edu/ page 26/129 pdf.

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].