1.0 Objective: To lay down a Procedure for Issuance, Use, and Retrieval of the Punches and Dies.

2.0 Scope: This procedure is applicable to the issuance, use, and retrieval of the punches and dies used in the production department.

3.0 Responsibility:

Officer, Executive – Production Department

Manager – Production Department

4.0 Procedure:

4.1 Issuance of dies and punches:

4.1.1 Issue required a number of dies and punches for a particular product as specified in the respective BMR.

4.1.2 All tooling is to be checked for any damage before assembly. In case of any deviation, report to the department head and QA.

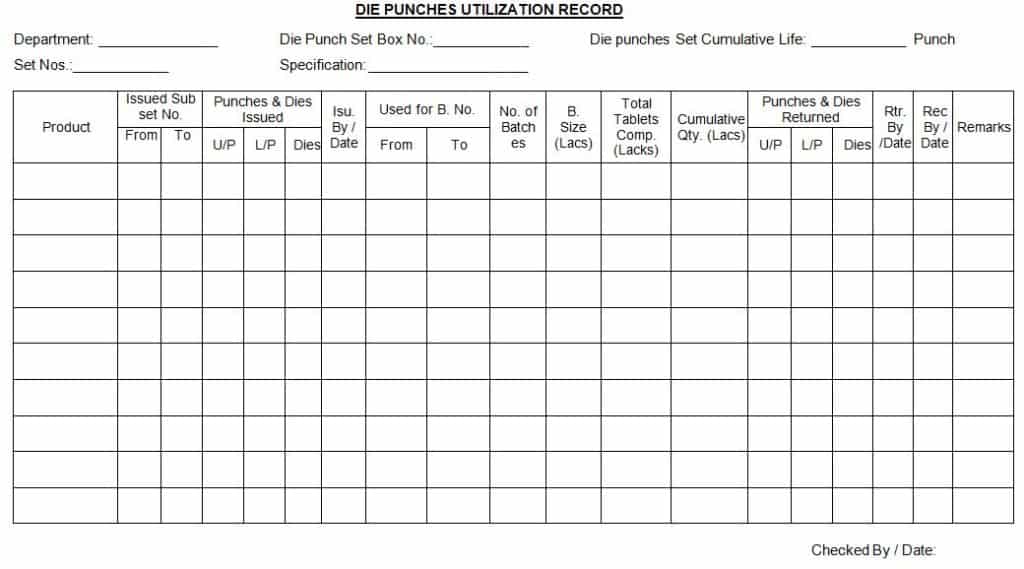

4.1.3 Record the details in the Punches and dies utilization record (Refer to Annexure- I).

4.2 Use of dies and punches:

4.2.1 Use the punches and dies on a rotation basis.

4.2.2 For 45 Station compression machine :

Use 1 to 45 subsets on the first issue. The punches and dies are to be issued in rotation so as to ensure that all the spare subsets of a particular set are being utilized uniformly.

For example, if a set of 50 nos. of punches & dies, then

1st issue – sub set no.1 to 45

2nd issue – sub set no.5 to 49

3rd issue – sub set no.9 to 3 and so on.

For 55 Station compression machine :

Use 1 to 55 subsets on the first issue. The punches and dies are to be issued in rotation so as to ensure that all the spare subsets of a particular set are being utilized uniformly.

For example, if a set of 60 nos. of punches & dies, then

1st issue – sub set no.1 to 55

2nd issue – sub set no.5 to 59 and so on

For 35 Station Compression machine:

Use 1 to 35 subsets on the first issue. The punches and dies are to

be issued in rotation so as to ensure that all the spare subsets of a particular

set are being utilized uniformly.

4.2.4 Make the entries as ‘✓’ for a subset issued and ‘—‘ for a sub-set not issued in annexure -I.

4.2.5 Use the correct tooling as per the instruction given in the BMR.

4.3 Retrieval of dies and punches:

4.3.1 After completion of the batches, remove the dies and punches from the compression machine.

4.3.2 Clean the punches and dies as per SOP “Polishing of Punches and Dies“

4.3.3 Transfer the cleaned punch set to the tool room and check the dies and punches for any defects as per SOP “Polishing of Punches and Dies”

4.3.4 Retrieve the dies and punches and make the entries in Annexure-I.

4.3.5 If any abnormality is found, isolate the product and punch set and keep it under hold.

4.3.6 Inform the Production and QA Incharge.

4.3.7 Investigate the cause of incidence and action plan to be prepared for further processing

4.3.8 Reject the punch set after the compression of five million tablets per sub-set.

5.0 Abbreviations:

BMR: Batch Manufacturing Record

QA: Quality Assurance

SOP: Standard Operating Procedure

Annexure: 1

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].