1.0 OBJECTIVE: To lay down the procedure for cleaning of Liquid tanks, Pipelines, and Filling machine.

2.0 SCOPE: This procedure is applicable for cleaning of Liquid tanks, Pipelines, and Filling machine in the liquid Oral department.

3.0 RESPONSIBILITY:

Production Officer, Production Executive.

4.1 PROCEDURE:

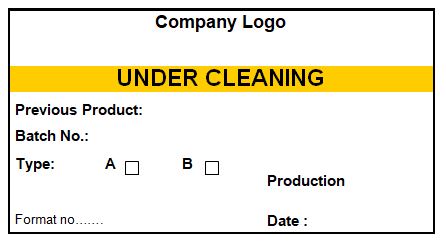

4.1.1 Before starting the cleaning, check that the tank is empty and affix the “UNDER CLEANING” label on the machine as per Annexure – I.

4.1.2 Put “OFF” the mains of the stirrer of the tank. Open the bottom valve of the tank. Start cleaning the tank with purified water using a hosepipe from inside and outside for at least 5 to 10 minutes. Let all this water get drained out continuously.

4.1.3 In case of suspensions or any product changeover, let a person with a clean uniform enter the tank, in the presence of a supervisor, and scrub the insides with a nylon brush particularly the “Hard to clean” areas like the curved inner surface. After thoroughly scrubbing, allow the person to come out of the tank.

4.1.4 Clean the tank again thoroughly by flushing purified water through the hose for at least 5 to 10 minutes or till the rinse water is clear and clean, Drain out all the water and close the bottom valve.

4.1.5 Affix the “CLEANED” label on the tank as per Annexure – I.

4.2 FOR TRANSFER LINE AND FILLING MACHINE:

4.2.1 Affix the “UNDER CLEANING” label on the machine as per Annexure – I.

4.2.2 Flush the transfer pump and transfer pipelines to the hopper of the filling machine with hot purified water for about 5 to 10 minutes. Drain out this water from the filling syringes and also from the hopper by opening the drain valve of the hopper.

4.2.3 Next open the cover of the hopper by opening the screws and scrubbing the inside of the hopper with a soft nylon brush. Clean again with purified water.

4.2.4 Open the syringes of the filling machine and clean them by dipping them in a bucket of hot purified water and scrubbing. Refit the washed syringes and close the lid of the hopper.

4.2.5 Again flush purified water through the transfer pump and pipelines into the hopper and syringes till the rinse water is clear and clean. Clean the filling machine surface and base with a wet cloth.

4.2.6 Affix the “CLEANED” label to the filling machine as per Annexure – I. Take line clearance from IPQC before the next batch.

5.0 ABBREVIATION (S):

IPQC: In-process Quality Check.

SOP: Standard Operating procedure.

Annexure-1:

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at Contact@pharmaguddu.com.