1.0 Purpose: To lay down the procedure for manual visual inspection of filled vials.

2.0 Aim: This Standard Operating Procedure is applicable for packing vaccines at the packing section.

3.0 Responsibility:

3.1 Trained operators for visual inspection activities of vials.

3.2 Officer is responsible for checking the activity.

3.3 IPQA shall be responsible for compliance as per this SOP.

3.4 Head/Designee QA shall be responsible for the authorization of the SOP.

4.0 Procedure:

4.1 Visual inspection of filled vials.

4.1.1 Check the cleaning status and working status of the manual visual inspection table of the visual inspection area and take line clearance from IPQA to carry out the visual inspection of vials.

4.1.2 Take out the material (vials) for visual inspection from the cold room, which are already issued from the warehouse as per “issuance and transfer of material to warehouse”.

4.1.3 Turn on the light of the manual visual inspection table.

4.1.4 Take the vials from the tray/ crate by hand.

4.1.5 Wipe the outer surface of vials with a dry lint-free mop (if required) for clear visibility.

4.1.6 Then hold the vials (as per the capacity to hold) between the middle finger and thumb.

4.1.7 Check the vials under the white and blackboard of the manual visual inspection cabinet (for any type of defects like crimping and color variation in seals, more/less volume, presence of particulate matter that is white, fiber, black, and glass particles, etc.).

4.1.8 Invert the vials 2-3 times (for the slow shake of liquid) and check carefully for any defect.

4.1.9 Keep accepted and rejected vials separately and paste the status label as per the “Status Labelling” SOP.

4.1.10 Transfer the accepted vials to the Cold room or labeling area as per the requirement.

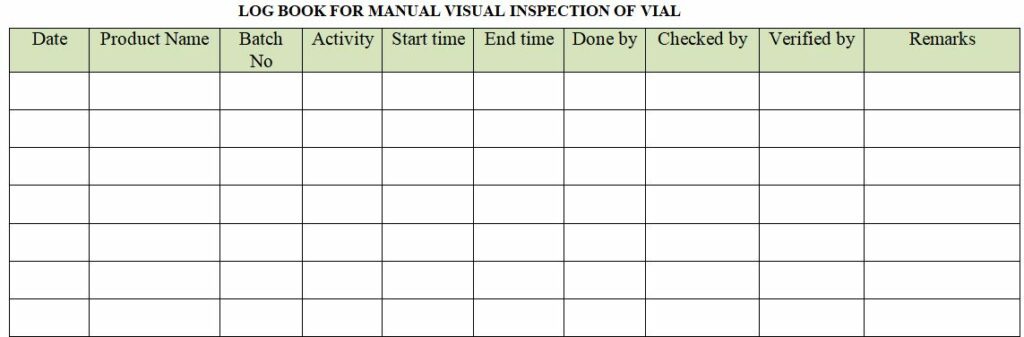

4.1.11 Record the activity detail of visual inspection in the log book as per “making entry in equipment usage Logbook” and respective BPR.

Note: 1 Only those visual inspectors who have passed the challenge test should be allowed to do the manual visual inspection of vials.

2 Revalidation of visual inspectors shall be done every year.

4. Visual inspectors must take a break for 2 hours, Rotate the trained manpower every 2 hours and make the entry in Batch packing records.

5.0 Abbreviations:

No. : Number

SOP: Standard Operating Procedure

BPR: Batch Processing Record

IPQA: In Process Quality Assurance

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].