1.0 Purpose: To lay down the procedure for the operation and cleaning of lyophilizer.

2.0 Aim: This Standard Operating Procedure is applicable to the cleaning and operation of the Lyophilizer, located on the production floor.

3.0 Responsibility:

3.1 Officer Production

3.2 Head Production

4.0 Safety considerations:

4.1 Persons who are familiar with the basic safety and accident prevention regulations and with sound knowledge regarding machine operation are allowed to work on the machine.

4.2 Do not remove installed protection devices.

4.3 Safety switches should not be bypassed.

4.4 Do not reach into the machine while it is running.

4.5 Do not climb on the machine during production

4.6 Do not reach over open-top protection covers.

4.7 Read all safety information for fluids used in the system. Material Safety Data Sheets for these fluids are provided in the Instruction Manual.

4.8 Do not tamper with door lock pistons.

4.9 Keep clear of door lock pistons.

4.10 The accumulation or use of dangerous cleaning agents will damage the freeze dryer and create hazardous conditions. The freeze dryer is not flameproof.

4.11 Keep away from the shelf stack when stoppering.

4.12 Do not tamper with pressure switch settings or any hydraulic safety devices.

4.13 When taking instrument measurements, verify gauges indicate correct values and the values are not confused by other operating conditions.

4.14 During production, moving machine parts should not be cleaned.

4.15 Do not clean the machine by spraying water on the machine.

4.16 Depressurize all pneumatic equipment/connections before opening any pneumatic equipment/connection for repair.

4.17 Use safety glass while cleaning the machine with compressed air.

6.0 Materials and reagents:

6.1 Filtered and preparation of 70% IPA

7.0 Procedure:

7.1 START UP:

7.1.1 Access level:

7.1.2 The Machine Lyofast 15 has four levels of passwords for the various activities of the lyophilizer:

Password Level Description:

1. AS_PUBLIC

2. AS_OPERATORS

3. AS_SUPERVISORS

4. AS_ADMINISTRATORS

7.1.3 Switch on the PC of the SCADA system.

7.1.4 The first screen of “Splash” will be displaced followed by the screen on the console having: Header; Mimic; Footer.

7.1.5 Log in to the system according to the assigned password.

7.1.6 Header portion will have:

7.1.6.1 Print the PC screen.

7.1.6.2 Login/logout of the system.

7.1.6.3 Start the Security Configuration or System Configuration.

7.1.6.4 Switching ON / OFF the main picture, i.e., Mimic, Console, Alarm, Recorder, Trend, Recipe Editor, Run Time Recipe, PLC I/Os, Setup, etc.

7.1.7 The footer portion will have the following:

Job Number, Machine Model, Current Date and time, Current Logged on the user, Current Control, Current Process, Show the current process, PLC Communication status, Recorder communication status, SQL Communication status.

7.1.8 Mimic is a graphical representation of the freeze dryer’s P&I Ds, in which the current status of the following will be displayed: Motors, flow valves, solenoid valves; Main isolation valve, Chamber door, Process Parameters shelf fluid inlet temperature, shelf fluid output temperature, condenser coil temperature, chamber vacuum, pump vacuum, Chamber pressure, Condenser pressure Chamber drain temperature.

7.1.9 Ensure the following pre-start requirements and Start-up Checks before starting the lyophilization cycle.

7.1.9.1 Check process & instrumentation diagrams to verify all vents are correctly installed and released to safe areas.

7.1.9.2 Start the Lyomaster compact(the SCADA program) before initiating a freeze-drying cycle.

7.1.9.3 Complete required daily maintenance procedures as defined in the Maintenance Manual.

7.1.9.4 Verify drying chamber is clean of broken vials, old stoppers, product deposits, and other contaminants.

7.1.9.5 When using a solvent to clean the chamber, remove the solvent by out-gassing (pumping down) the system.

7.1.9.6 Verify condenser coil is defrosted, and the condenser drained.

7.1.9.7 Verify chamber/condenser isolation valves are closed.

7.2 Operation of Loading Pizza Door:

7.2.1 Enable the slave panel by clicking on the slave panel on the “console” screen.

7.2.2 Bring down all loading shelves to the full collapsed state by pressing the shelf down arrow( ) on the slave panel.

7.2.3 Press once the “Home loading” button on the “Alarm” screen of the PLC. A green-filled circle should appear.

7.2.4 Press the Door open-up arrow ( ) key on the slave panel on the loading side of the lyophilizer to open the loading pizza door.

7.2.5 Bring up loading shelves to the level of the door and to the loading platform of the loading door by pressing the shelf up arrow ( ) key on the slave panel.

7.2.6 After loading is complete, bring down and close the door by pressing the shelf down arrow key ( ) on the slave panel.

7.3 Shelves Loading:

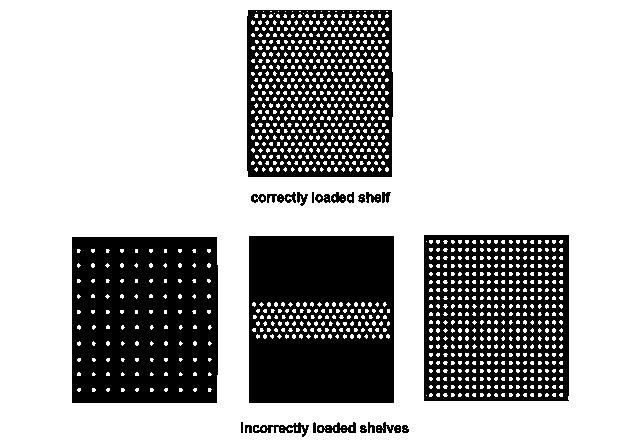

7.3.1 Before collapsing the shelves, ensure that they are correctly loaded or completely empty and clear of all foreign objects.

7.3.2 Load the shelves of the lyophilizer by moving them up and down during the loading. With the help of the up and down arrows on the slave panel on the sterile side i.e. the loading side of the lyophilizer.

7.3.3 Load and verify that shelves are loaded evenly as follows:

Shelves Loading:

7.4 Closing the Chamber Door:

7.4.1 Check that the door seal and chamber mating surface are clean before closing the chamber door.

7.4.2 Use a damp cloth to remove any deposits as required. Do not use any sharp tools to clean the seal.

7.4.3 Carefully close the chamber door, verifying the temperature probe wires are clear of all door mechanisms.

7.4.4 Pre-Cycle Checks

Perform the following before starting the freeze-drying cycle:

7.4.4.1 Verify the Control Power key switch in the control cabinet is in the ON position.

7.4.4.2 Verify no alarms are present on the Alarm Screen. Clear all alarm conditions.

7.4.4.3 Check the Mimic screen and verify the chamber pressure displayed is OK.

7.5 Auto Control Operation :

7.5.1 Select the “Auto” button in the console screen of the SACDA system.

7.5.2 The following process can be performed in the auto cycle:

7.5.2.1 freeze-drying

7.5.2.2 condenser defrosting

7.5.2.3 CIP

7.5.2.4 SIP, shelf, and main valve bellows test vacuum leakage test

7.5.3 To start a Freeze-drying Automatic Cycle.

7.5.3.1 Login as required by the access control system.

7.5.3.2 Click the “Browse existing recipes” command button and press the “Download Recipe” command button to download the pre-decided recipe.

7.5.3.3 When the selected recipe is downloaded successfully, the following message will pop up: “ [Test recipe] has been saved to the database: Lyorecipes.”

7.5.4 Select the Console button from the Header toolbar.

7.5.5 Enable the Auto mode.

7.5.6 Select the Start Auto FD button to start a freeze-drying automatic cycle.

7.5.7 At the end of the FD cycle the next step At the end of the aeration step the chamber is automatically aerated to atmospheric pressure, after the aeration step, the SCADA will prompt for the end of the cycle.

7.5.8 When the chamber is at atmospheric pressure, open the chamber door and unload the

Shelves. Inspect inside the chamber and clean it if necessary.

7.5.9 Condenser Defrosting:

The accumulation of ice is to be removed from the condenser coil by heating the condenser by help pure steam :

7.5.9.1 Login as required.

7.5.9.2 Ensure that the main door is closed and all valves are in their normal state.

7.5.9.3 Select the Console button from the Header toolbar.

7.5.9.4 Enable the Auto control mode.

7.5.9.5 Select the Condenser Defrosting button.

7.6 CIP Cycle:

7.6.1 To clean the chamber and the condenser after the lyophilization cycle, the CIP cycle is to be run as follows.

7.6.1.1 Check the connection of the purified and WFI to the CIP utility manifold of the lyophilizer.

7.6.1.2 Open the manual valve of the purified water loop(for the first wash) and WFI (for the second wash)to the utility manifold of the lyophilizer.

7.6.1.3 Login as required by step No: 4.1.2

7.6.1.4 Ensure that the door is closed and all valves are in their normal state.

7.6.1.5 Select the Console button from the Header toolbar.

7.6.1.6 Enable the Auto control mode.

7.1.6.7 Select the CIP command button.

7.7 Ram Bellows Integrity Test:

7.7.1 Perform integrity test of the Ram bellows as follows:

7.7.1.1 Login as required.

7.7.1.2 Ensure that the door is closed and all valves are in their normal state.

7.7.1.3 Select the Console button from the Header toolbar.

7.7.1.4 Enable the Auto control mode.

7.7.1.5 Select the Shelf Bellows Integrity Test command button.

7.7.1.6 Click the OK command button in the window that popped up after the completion of the test.

7.7.1.7 If the Test fails do the maintenance of the Bellows and repeat the test.

7.8 SIP Cycle:

7.8.1 To clean the chamber and the condenser after the lyophilization cycle, and CIP cycle, a SIP cycle is run as follows:

7.8.1.1 Check the connection of the Pure steam to the designated place above the chamber of the lyophilizer.

7.8.1.2 Open the manual valve of the Pure steam of the lyophilizer.

7.8.1.3 Login as required.

7.8.1.4 Ensure that the door is closed and all valves are in their normal state.

7.8.1.5 Select the Console button from the Header toolbar.

7.8.1.6 Enable the Auto control mode.

7.8.1.7 Select the SIP command button.

7.9 Leak Rate Test:

7.9.1 Before the start of the new freeze-drying cycle and before loading the selves perform the System leak rate test as follows:

7.9.1.1 Login as required.

7.9.1.2 Ensure that the door is closed and all valves are in their normal state.

7.9.1.3 Select the Console button from the Header toolbar.

7.9.1.4 Enable the Auto control mode.

7.9.1.5 Select the Vacuum leak test command button.

7.9.1.6 Click the OK command button in the window that popped up after the completion of the test.

7.9.1.7 If the Test fails do the maintenance system to arrest the leakage and repeat the test.

7.10 Filter Integrity Test:

7.10.1 Ensure that the door is closed and all valves are in their normal state.

7.10.2 Perform the filter integrity test as per SOP.

7.10.3 If the test fails, do the maintenance system to arrest the leakage by changing the filter and repeating the test.

7.10.4 If the test passes, proceed to the next steps.

7.11 Manual Operation:

7.11.1 Repeat step number 7.1.9 to 7.3

7.11.2 Perform the following before starting the freeze-drying cycle:

7.11.2.1 Verify the Control Power key switch in the control cabinet is in the ON position.

7.11.2.2 Verify no alarms are present on the Alarm Screen. Clear all alarm conditions.

7.11.2.3 Check the Mimic screen and verify the chamber pressure displayed is OK.

7.11.2.4 Select Shelf Temperature Regulation on the Console screen and activate the shelf temperature control function.

7.11.2.5 Change the shelf temperature set point as per the pre-cooling requirement of the selves.

7.11.2.6 Start the chart recorder:

7.11.2.7 Ensure there is sufficient chart paper and ink.

7.11.2.8 Turn the recorder on and allow it to run for five minutes as an operational check.

7.12 Shelf Cooling/Product Freezing:

7.12.1 Activate the shelf cooling system as follows:

7.12.1.1 Verify the chamber/condenser (from the mimic screen) main valve is closed.

7.12.1.2 Verify the chamber (from the mimic screen) vent valve is closed.

7.12.1.3 Set the shelf cooling temperature to the required value.

7.12.1.4 Select Shelf Temperature Regulation on the Console Screen to activate the shelf temperature control function. Verify the mimic screen displays the operating state of circulating pumps and compressors.

7.12.1.5 Verify the Mimic screen shows the cooling solenoid valve open.

7.12.1.6 Monitor the shelf temperature.

7.13 Condenser Cooling:

7.13.1 Start the condenser cooling sequence as follows:

7.13.1.1 Verify condenser defrosting valve is closed.

7.13.1.2 Verify condenser inlet valve is closed.

7.13.1.3 Verify main isolation valve is closed.

7.13.1.4 Select the Condenser Cooling button on the Console Screen and enable the condenser

7.13.1.5 After the condenser temperature falls to the desired temperature, leave the condenser in this condition for 10 minutes before proceeding with the vacuum pump down.

7.14 Vacuum Pump Down:

7.14.1 Verify the following:

7.14.1.1 All of the chamber and condenser valves are closed.

7.14.1.2 Ensure associated Mimic screen functions are clear.

7.14.1.3 Ensure that the gas ballast Valve is set in accordance with the manufacturer’s instructions.

7.14.2 Select Vacuum Pump on the Console Screen to start the vacuum pump in a ‘warm-up’ mode while the vacuum valve is kept closed.

7.14.3 With a manually operated gas ballast valve, the valve is normally set half open but is fully open when pumping solvents or condensable vapors.

7.14.4 Select the Control Vacuum Set point field on the Console screen, and then enter the vacuum set point along with the lower and the higher limit of the deviation from the set point.

7.14.5 When the condenser coil is -40°C or below (check on the recorder screen display) and 10 minutes have passed since the start of condenser cooling, perform the following at the Console screen:

7.14.5.1 Open Main Isolation Valve.

7.14.5.2 Open the Vacuum Valve.

7.14.5.3 Enable vacuum valve control.

7.14.6 Verify the Mimic screen shows the following:

7.14.6.1 Main valve open.

7.14.6.2 Vacuum valve open.

7.14.6.3 Vacuum pump running.

7.14.6 Shelf Heating:

7.14.6.1 Set the required shelf heating temperature at the Console screen display.

7.14.6.2 Verify the chamber pressure is at the Vacuum Setpoint.

7.14.6.3 Verify the control system maintains the shelf oil temperature within the alarm limit (usually ±4°C from the set point, which is specified at the Engineering Parameters screen.

7.14.7 After the specified time of the primary drying move to the next step of the recipe i.e secondary drying.

7.14.8 Increase the shelf temperature as follows and do the following:

7.14.8.1 Set a higher value temperature set point at the Console screen display.

7.14.8.2 Continue drying process after product temperature stabilizes at new set point.

7.14.8.3 Hold the process for the specified time after that move to the next step of the recipe.

7.15 End of Cycle:

7.15.1 Test the product by performing a chamber pressure rise test as follows:

7.15.1.1 Close the main isolation valve at the Console Screen display.

7.15.1.2 Observe the rise in chamber pressure.

7.15.1.3 If the system prompts for “pressure rise test pass” then process to the next step, if the system prompts for “pressure rise test fail” then continue the secondary drying as per the instruction in the recipe.

7.15.1.4 Pre-aeration step:

To stopper the free dried product in the vial under a partial vacuum aerate the chamber to the set point of ‘Pre-aeration pressure’ (typically below the atmospheric pressure).

7.15.1.5 Stoppering:

Activate this step to put the stoppers on the lyophilized vials for a predetermined time.

7.15.1.6 Chamber Aeration

Select the Chamber Aeration button on the Console screen or on the slave panel. The chamber should automatically aerate to atmospheric pressure.

7.16 Unloading:

7.16.1 When the chamber is at atmospheric pressure, open the chamber door and unload the shelves.

7.16.2 Inspect inside the chamber and clean if necessary.

7.16.3 Condenser Defrosting: To remove the accumulated ice on the condenser coil, introduce pure steam in the condenser to raise the temperature of the condenser.

7.17 Cleaning of the lyophilizer:

7.17.1 Wipe the surface of the shelves and the chamber with a sterile clean lint free disposable mop to remove any debris ( broken vials, stoppers )

7.17.2 Use WFI to clean the chamber, shelves, and interior door surface.

7.17.3 Wipe the shelves and the chamber with cleaning agent 70%IPA using a sterile lint-free disposable mop.

7.17.4 Allow chamber door to remain open to facilitate chamber drying, and permit cleaning.

7.17.5 Allow the vapors to escape.

7.17.6 Close the chamber door.

8.0 Abbreviations:

QA: Quality Assurance

SOP: Standard Operating Procedure

IPA: Isopropyl alcohol

No. : Number

PR: Production

Rev.: Revision

CIP: Cleaning in Place

SIP: Sterilization in Place

WFI: Water For Injection

PLC: Programmable logic controller

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].