1.0 OBJECTIVE: 1.1 To lay down the procedure for the operation & calibration of water bath

2.0 SCOPE: 2.1 This SOP is applicable to Analytical development at Pharmaceutical Lab.

3.0 RESPONSIBILITY

3.1 Officer/Executive – Analytical Development

3.2 Manager-AD for overall compliance with this procedure

4.0 ACCOUNTABILITY

4.1 Manager-AD

5.0 PROCEDURE

5.1 Operating procedure

5.1.1 Ensure that the instrument is clean and within the due date of calibration.

5.1.2 Check the water level in the water bath and fill the bath with purified water up to approx. the level above the SS tray in the bath.

5.1.3 Place the sample vessel / volumetric flask in the bath. Add sufficient water and if the volumetric flask starts floating then minimize the water level through the outlet drain.

5.1.4 While doing analysis for a long time the minimum water level is maintained by adding water to the bath manually whenever the water level goes down due to evaporation by continuous heat.

5.1.5 Switch on the main power supply and then switch on the bath by using MCB provided on the front side of the water bath.

5.1.6 Set the required temperature.

5.2 KEYS on Temperature Controller:

Keypad consists of a total of 3 keys & 3 LED Indicators.

LED Indicator OP1 for heater On/Off.

(LED On = Heater On & LED Off = Heater Off)

LED Indicator OP3 not used.

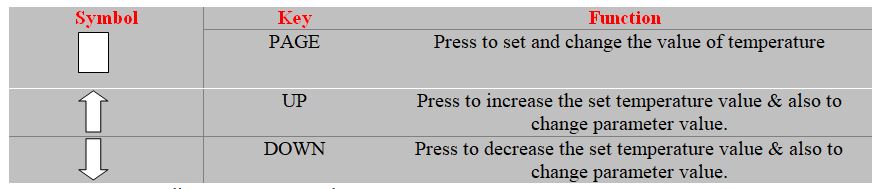

Keys & their description are given below:

Symbol Key Function

PAGE Press to set and change the value of the temperature

UP Press to increase the set temperature value & also to change the parameter value.

DOWN Press to decrease the set temperature value & also to change the parameter value.

5.3 Setting procedure for temperature :

5.3.1 Use the ‘UP’ and ‘DOWN’ arrow keys by continuously pressing the PAGE key on the temperature controller to set the required temperature. The lower display shows the set value and the upper display shows the actual value of the water temperature in the bath.

5.3.2 To store the set value of temperature release the ‘PAGE’ key on the controller. The ‘OP1’ LED of the temperature controller will indicate the on/off status of the heater.

5.4 Calibration procedure :

5.4.1 The equipment calibration should be performed on yearly basis by an external agency or Whenever there is a breakdown and after maintenance, calibration should be done.

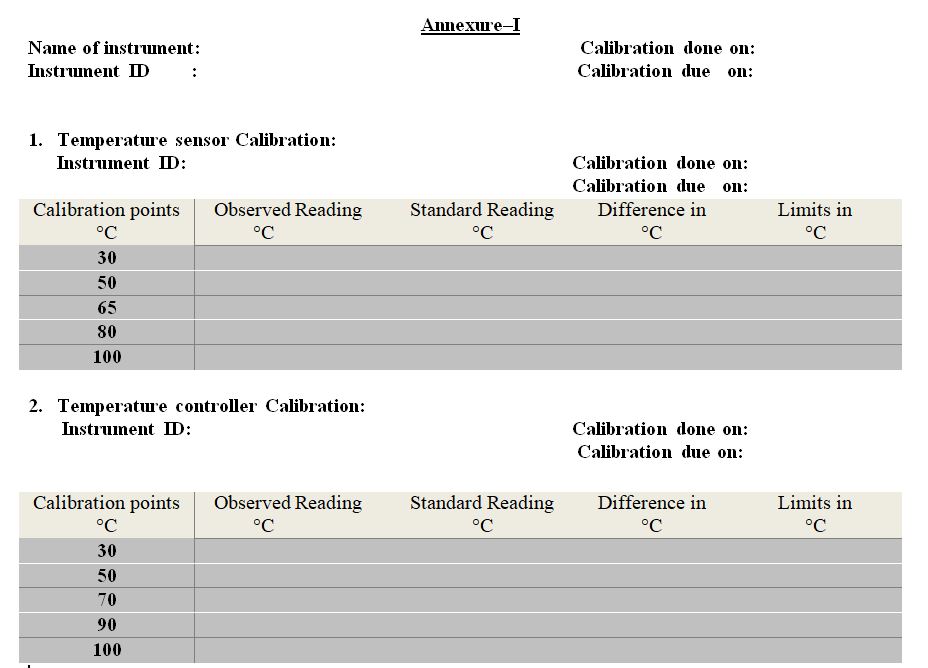

Calibration frequency: 1 year ± 30 days. 5.4.2 The equipment calibration is performed in two parts;

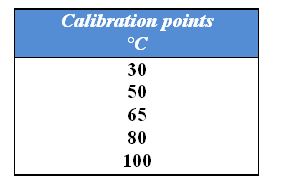

1. Temperature sensor Calibration:

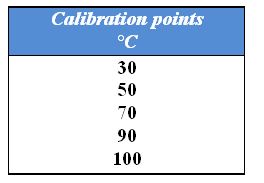

2. Temperature controller Calibration:

5.4.3 After completing the calibration make an entry in the calibration record of the water bath and fill in the annexure given below.

Acceptance Criteria: ±2°C

5.5 Care and handling:

5.5.1 Ensure proper earthing and proper supply voltage.

5.5.2 No chemicals should be split on the bath.

5.5.3 While switching ON, Ensure that there should be some water in the bath sufficient to dip the heater.

5.5.4 Never set the bath temperature above 100 °C.

5.5.5 Switch off the instrument when not in use.

6.0 Abbreviation:

SOP: Standard Operating procedure

AD: Analytical Development

MCB: Miniature Circuit Breaker.

°C: Degree Centigrade.

7.0 Annexure

Annexure-I: Calibration of water bath.

Related SOP: SOP for Magnetic stirrer

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].