1.0 Purpose: The purpose of this SOP is to provide instruction for the Retesting and Resampling of raw materials and intermediates.

2.0 Objective: To provide a documented procedure for Retesting and Resampling of raw materials and intermediates.

3.0 Scope: This procedure is applicable for the Retesting and Resampling of raw materials and intermediates in the QC department.

4.0 Responsibility :

4.1 QC Chemist / QC Officer to perform the sampling as per this SOP.

4.2 QC –Head/in charge of overall compliance with this SOP

5.0 Procedure:

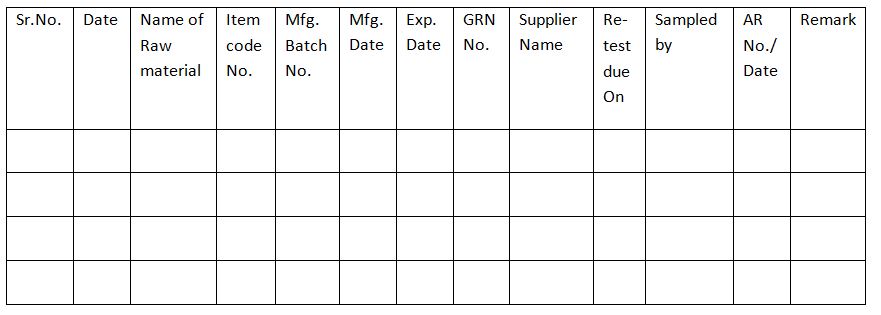

5.1 After the receipt of the Re-testing intimation note from the Raw material store department, QC Chemist carries its entry in the respective Re-testing logs and test report no. to raw materials or intermediate.

5.2 Before the sampling, the QC officer shall follow the proper gowning procedure.

5.3 Collect samples for re-test as per the sampling plan.

5.4 After completion of sampling put the “UNDER RETEST” label and do the required tests (e.g. assay, microbial limit test, water content/LOD, pH, specific optical rotation, etc.) as per the Standard Analytical Procedure and STP.

5.5 After completion of testing, put the status of “APPROVED/REJECTED” along with the next re-test date on the re-tested containers.

5.6 Re-testing of any raw materials should be done as per the frequency.

5.7 The frequency of re-testing for raw material is every year, and for intermediate is every six months. The re-test due date of raw materials shall not be more than the expiry date.

5.8 Re-testing of raw material should be performed on a FIFO (first in first out basis). The re-testing of raw materials should be performed, the basis of whose due date for the re-test is earlier.

6.0 Reference Document:

Re-testing of raw materials logbook.

7.0 Abbreviations:

SOP: Standard operating procedure

QC: Quality Control

LOD: Loss on drying

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].