Learn About the Standard Operating procedure for Static Pass Box in Pharmaceuticals along with their Purpose, Scope, Responsibility, Operation, and Cleaning.

1.0 Purpose: To lay down the standard operating procedure for cleaning and Operating of static pass box.

2.0 Scope: This standard operating procedure is applicable for the cleaning and Operation of static pass boxes in the pharmaceutical industry.

3.0 Responsibility:

3.1 Officer production to implement this SOP

3.2 Head Department for overall compliance to this SOP

4.0 Operation of static pass box:

4.1 Ensure the cleanness of the static pass box before transferring the materials

4.2 Switch on the static pass box and start the UV light and blower before 30 minutes.

4.3 Open the door from one side, and another side door should be closed at the same time.

4.4 Put the materials to be transferred inside it and close the door.

4.5 To receive the materials, open the other side of the door.

4.6 Replace the UV light after usage of 6000 hours.

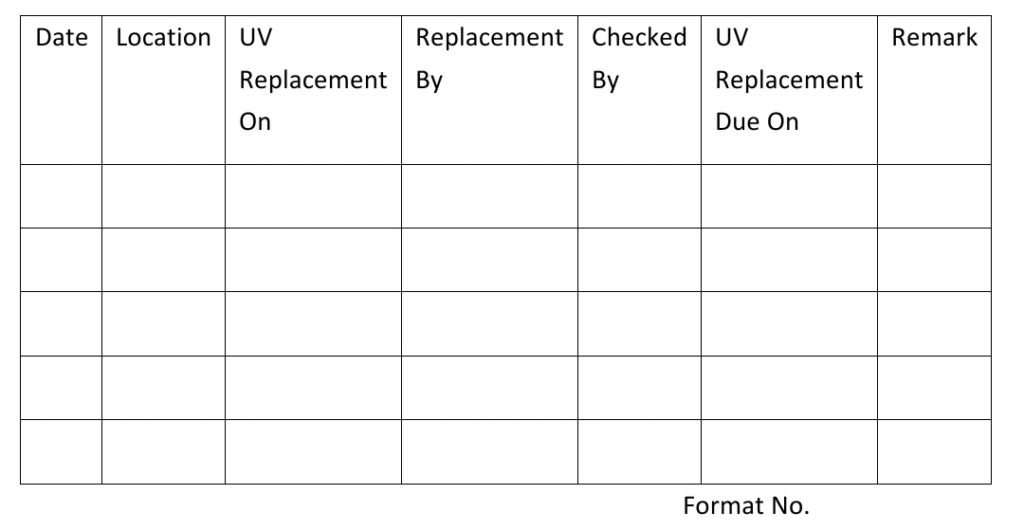

4.7 Fill in the replacement details of the UV light pump as per Annexure—I.

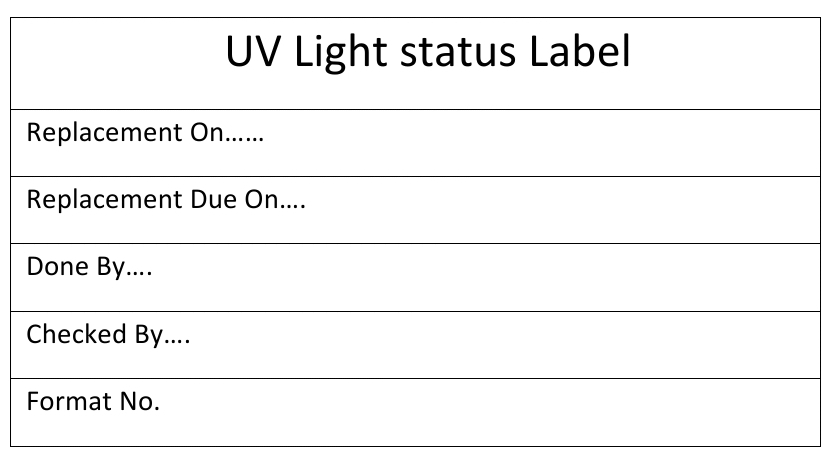

4.8 Make the entries on “label” as per Annexure—II.

4.9 Clean the filter as per the required frequency.

5.0 Cleaning of static pass box:

5.1 Switch off the static pass box before starting the cleaning.

5.2 Make sure the UV light is switched off before starting cleaning.

5.3 prepare the IPA 70 percent as per the given SOP.

5.4 Open the door and use a lint-free duster or cloth to clean ( Deep the cloth in IPA 70% to clean) the internal and outer surfaces of the static pass box.

6.0 Abbreviation:

SOP: Standard operating procedure

IPA: Isopropyl alcohol

%: percentage

UV: Ultraviolet

Annexure-I

Annexure-II

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at Contact@pharmaguddu.com.