1.0 Objective: To lay down a procedure for the Verification of the sugar dissolving tank, manufacturing tank, and holding tank.

2.0 Scope: The procedure is applicable to the verification of the sugar dissolving tank, manufacturing tank, and holding tank, installed in the Liquid orals Department.

3.0 Responsibility

Officer, and Executive – Production Department for implementation of this procedure.

Manager – Production Department for overall compliance to this procedure

4.0 Procedure

4.1 Calibration of tank

4.1.1 Physically verify the tank is cleaned.

4.1.2 Check the calibration status of the weighing balance, it should be calibrated.

4.1.3 Check the temperature of purified water is 25±1ºC, if not maintain it.

4.1.4 Place the SS container on the weighing balance and tare it.

4.1.5 Weigh 49.80 kg of purified water, it will be equivalent to 50 lits of purified water

( considering density of water 0.99602 gm/ml)

4.1.6 Manually Transfer the purified water to the tank.

4.1.7 Ensure that there is no loss during transfer.

4.1.8 Verify the water level in the tank on baffle plate marking and record the observation.

4.1.9 The difference between theoretical volume ( Tv) and checked volume (Cv) should be in prescribed tolerance limits.

4.1.10 Repeat step no. 4.1.3 to 4.1.9 with 49.80 kg of purified water till the required volume of purified water is transferred.

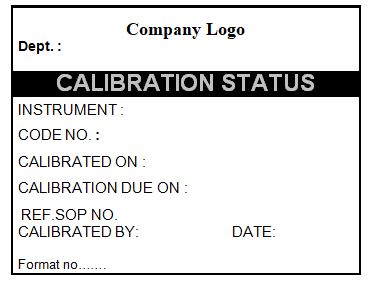

4.2.11 If the calibration is satisfactory, affix the calibration label to the side of the tank as per Annexure-I.

Note: If the calibration is not satisfactory, the apparatus shall be rectified by the engineering dept. Recalibrate the apparatus after maintenance.

4.3 Frequency: Once a year.

Related Post: Isopropyl alcohol 70 percentage Preparation SOP

5.0 ABBREVIATION(S)

SOP: Standard Operating Procedure

gm: gram

ml: Milliliter

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at Contact@pharmaguddu.com.