Human bodies are natural hosts to harmful bacteria, and if we’re sick or infected, dangerous viruses and fungi are as well. We also constantly shed tons of hair and skin cells and breathe out a plume of various microorganisms. So following the Gowning procedure in CleanRoom becomes an important task for working persons.

Today Life science businesses put in a lot of effort to avoid any kind of physical, chemical, or biological contamination during the manufacturing process.

Product contamination is a serious problem. The loss of a single batch could cost millions of dollars if it is discovered during manufacturing. The costs of legal action and compensation may be incalculable if a contaminated product went undetected, got into circulation, and caused illness or death.

Gowning Process in CleanRoom Area

Gowning or Donning and Doffing of PPE is basically putting on clothing covers, masks, and gloves that isolate your body from the clean room environment. Gowning is more involved than just slipping on a coverall and going to work.

To ensure full coverage of the body and maintain cleanliness of protective clothing, the process of dressing is essential. The company decides how complicated the gowning procedure should be, but it also depends on how sensitive the workplace is. For instance, gowning will be much more stringent for a Grade A pharmaceutical Filling operation than for a Grade D packaging operation.

A few gowning ideas are common to all cultures, Like having a completely clean body, hair, outfit, and shoes before even beginning the process. removing everything that is not required in the cleanroom area. All personal items, jewelry, electronics, and even makeup would fall under this category. Avoid touching environmental surfaces while dressed, such as lockers, floors, and walls. likewise, avoiding making contact with clothing, gloves, masks, and covers’ exteriors.

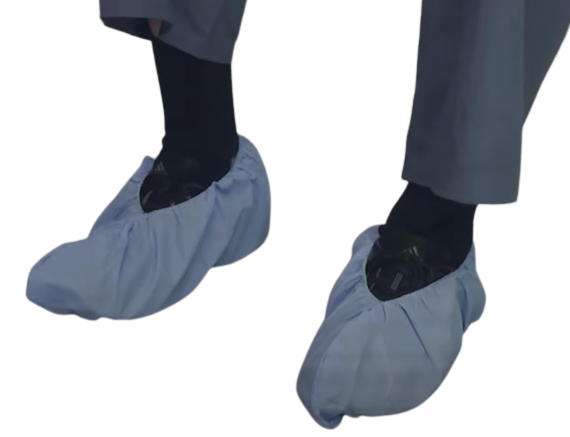

We’ll be using sterile gloves, a hairnet (also known as a bouffant), a beard cover, safety glasses, and shoe covers for general gowning. The procedure starts as soon as you walk into the changeroom, also known as the staging area. Wear your hairnet and, if necessary, use a beard cover.

Jewelry and all other personal items must be kept in the locker. Then, if you’re still wearing makeup, it’s time to take it off and wash your hands while cleaning your arms all the way to the elbow. Upon choosing the appropriate size of scrubs. Put street clothes in the locker after taking them off up to socks. Use 70% IPA to sanitize your arms and hands. Put on a scrub top by taking it off. then come to your scrub bottoms. Keep the clothing away from the wall, bench, lockers, and especially the floor!

Read Also: CleanRoom Classification

Gowning Procedure for Grade D CleanRoom area

It’s time to put on dedicated footwear if all you’re doing is general gowning for a grade D area likewise shoe covers. Additional footwear will be provided if you are gowning for aseptic procedures later on during Stage 2 gowning in the aseptic entry area. once you’ve cleaned and disinfected your hands. Grab a set of sterile gloves. without touching the glove’s outer layer, open the package. Always make contact with the internal surfaces of gloves when handling them with bare hands. Gloving correctly requires practice. Put on the gloves and then clean them with 70% IPA. then, following the putting on of your safety glasses.

Entry into Sterile Area

After the aseptic gowning is finished, you’re now prepared to enter the cleanroom after one last rinse of 70% IPA on your gloved hands. To keep your hands sterile, make sure to leave all of your plastic wrap on the bench. Open the door with your elbow, shoulder, or hip as you enter to avoid contaminating your sterile gloves.

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].