Rotameter is a safe, easy, and reasonably priced flow measurement tool. The flow rate of a liquid or a gas is thus measured with this equipment. This meter has a tapered tube that passes through a floating internal component. Rotameters are also known by the names Gravity flow meters, Mechanical flow meters, and Variable area flow meters. The term “gravity” refers to the requirement that the rotameter is installed vertically in gravity flow meters.

Rotameter Principle:

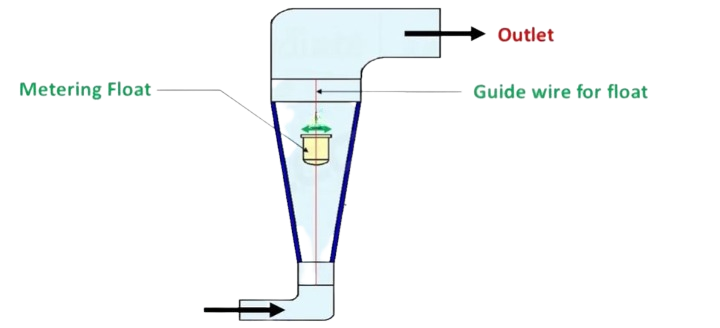

It consists of a verticle, a tapered and transparent tube in which a plummet is placed. During the fluid flow through the tube, the plummet rises and falls because of variation in flow. The Rotameter principle works on of force of gravity and upthrust force exerted by a fluid.

Rota Meter Construction:

- It consists of a verticle tapered tube, which is mounted with a narrow end down.

- The tube is usually made of glass to which a linear scale is attached.

- A solid plummet is placed in the tube (the diameter is smaller than the narrow end of the tube).

- Plummet/float may be made of lead, aluminum, glass, and plastic.

Working:

The first rotameter is fitted on a pipe, as flow is moving in an upward direction through a tapered tube, and the flow of fluid varies. The plummet, which is surrounded by the fluid, rises and falls depending on the rate of flow, the greater the flow rate, the higher the plummet rises in the tube.

Due to gravity and drag, respectively, the float in the rotameter is subject to two forces acting in opposite directions.

The float is pulled upward from gravity by the liquid flow. After a while, the flowing area reaches a place where the force applied to the floating body is exactly equal to the weight of the plummet. Therefore, the plummet will reach equilibrium once the area where it is moving causes enough drag to equal its own weight.

The distance the plummet is raised when gravity and its weight are both stable depends on how quickly the liquid is moving through the tapered tube.

The flow may be read using the upper edge of the plummet as an index (linear scale). The reading can be sent for recording, integrating, and controlling purposes.

Types of Rotameters:

Basically, Rotameter has three types:

- Glass tube rota meter

- Metal tube rotameter

- Heavy duty rotameter

1. Glass tube Rotameter:

As the name indicates, it’s made of borosilicate glass, and float can be manufactured by metal (usually stainless steel ), glass, and plastic.

Glass tube rotameter cannot be used in water over 90°C and a high pH that softens glass.

Note: Few company provides Glass tube rotameters, that can withstand up to 120°C temperature.

Glass tube rotameter cannot be used in caustic soda and hydrofluoric acid.

2. Metal tube Rotameter:

Metal tube Rotameter is Made of aluminum, brass, or stainless steel, it is easy to use for higher temperatures and pressure.

Since they are not transparent, mechanical, or magnetic flow, So the outside of the tube is not used to determine the float position.

Their spring and piston combination determine the flow rate, So it is easy to use with fluids like hot and strong alkalis, fluorine, hydrofluoric acid, hot water, steam, sour gas, additives, and molten metals.

They can be operated up to 750 psi, and 540°C temperature, and can measure flow up to 4000 GPM of water or 1300 scfm of air.

3. Heavy Duty/ Industrial pressure transducers:

Heavy-duty/ Industrial pressure transducers feature a much more rugged enclosure than other transducers.

They are intended for use in tough industrial environments.

They also frequently have a scaled 4-20mA output, which gives significantly higher resistance to electrical noise, which is prevalent in industrial settings.

Read Also: What is Pitot Tube

Parameters:

The following parameters need to be considered while selecting rotameters.

- Operating pressure

- Temperature of liquid

- Diameter of pipe

- Indicating the type of scale

- Requirements of valve

Application of the Rotameter:

- It is used in the chemical industries, and oil industries.

- It is used for gas and Liquid.

- Used to measure oxygen flow rate in medical areas.

Advantages and Disadvantages of Rota meter:

Advantages:

- Rota meter required no external power or fuel, it used only the inherited properties of the fluids along with gravity to measure the flow rate.

- A Rotameter is also a relatively simple device that can be mass-manufactured out of cheap materials, allowing it for widespread usage.

- Clean glass is used which is highly resistant to thermal shock and chemical reactions.

Disadvantages:

- Rotameter is not generally manufactured in size greater than 6 inches, but bypass design is sometimes used on very large pipes.

- Its accuracy is ± 0.5 to 10%.

- The glass tube is tough to handle.

- It is not easily adapted for reading by machine.

FAQs:

Ans: The volumetric flow of fluids and gases is measured using flow meters called rotameters. The terms “rotameter” and “flow meter” are used synonymously, therefore there is no such difference between them.

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].