For high-shear mixing, the Silverson homogenizer is highly used by many industries over the last 60 years. It is able to mix liquid to liquid and liquid to solid at the speed of up to 8000 r.p.m. In this article, we will discuss the Silverson mixer, its applications, principles, construction, working, advantages, and limitations.

Principle:

The Silverson high shear mixer operates based on the principle of shearing force. With the help of high-speed rotors, it generates high shearing forces and turbulence within the mixture.

Construction of Silverson Emulsifier Mixer:

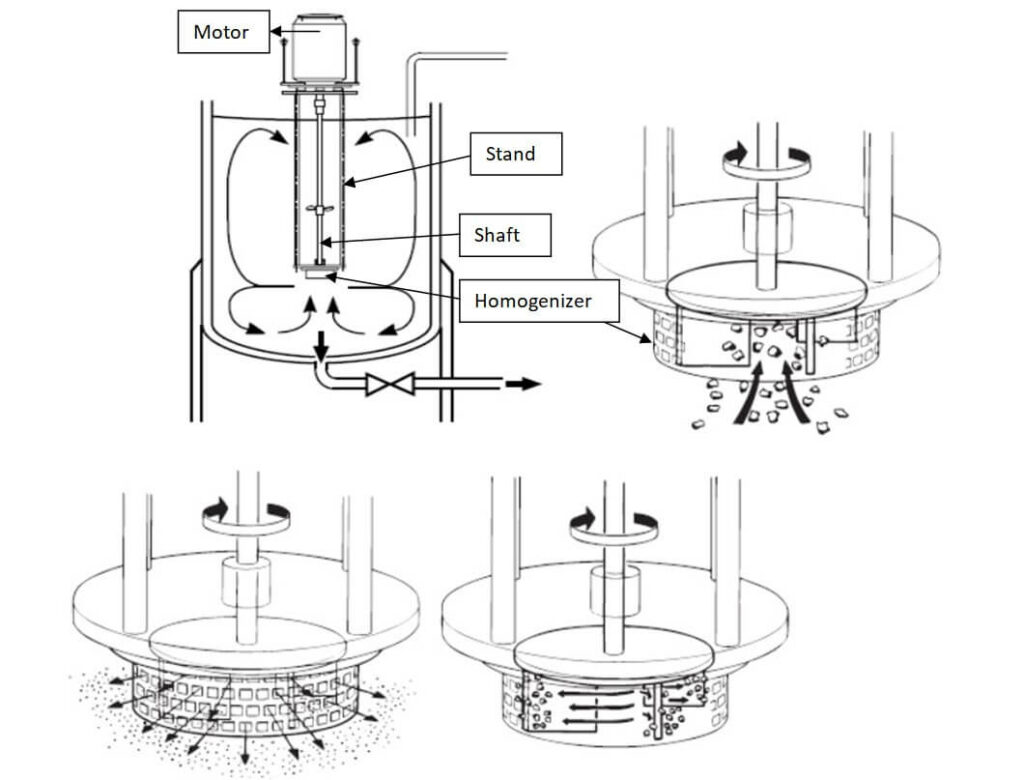

So, there’s this Silverson machine that has long supporting columns and a central part. I’ve included a picture below to show you what it looks like. The central part has a shaft that connects one end to the motor and the other end to the head. The head carries turbine blades, and they’re surrounded by a mesh. The mesh is covered by a protective cover that has openings.

The Silverson mixer homogenizer also comes with the following:

Disintegrating head: This is great for mixing or breaking down solids in general.

Square hole high shear screen: This screen is designed for making emulsions and preparing fine colloid suspensions using high shear forces.

Emulsor screen: This one is designed for lower shear intensity and is used for making liquid/liquid mixtures and emulsions.

Axial flow head: You can use this in combination with one of the screens mentioned earlier to make the liquid flow upwards. It helps reduce air bubbles or maintain large mixtures. Just be careful because if you mix at high speeds, the liquid might splash out of the container.

Related: Turbine Mixture

Working of Silverson Emulsifier Mixer:

The emulsifier head is placed in the vessel containing immiscible liquids in such a way that it should get dipped into it. When the motor is started the liquids are sucked through the fine holes and the oil is reduced into fine globules due to the rotation of the blades.

Here’s how the three-stage process works:

First, the rotor blades inside the precision-machined mixing work head rotate at high speeds. This creates a strong suction force, drawing both liquid and solid materials into the rotor/stator assembly, as shown in the figure below.

Once inside, the materials are subjected to a milling action due to the centrifugal force. They move towards the outer edge of the work head, where there is a precision-machined clearance between the ends of the rotor blades and the inner wall of the stator. This milling action helps further break down and mix the materials, as in the figure below.

Finally, there is an intense hydraulic shear process. The materials are forced out through small holes (perforations) in the stator at high velocity. They then pass through the machine outlet and continue along the pipework. At the same time, fresh materials are continuously drawn into the work head, maintaining the mixing and pumping cycle.

Applications of Silverson Mixer:

- The Silverson mixer can be used for many purposes. It can mix, emulsify, homogenize, solubilize, suspend, disperse, and disintegrate solids.

- One of its main applications is for homogenizing different products, such as creams, ointments, lotions, sauces, and flavor emulsions. It helps make these products consistent and smooth.

- It can quickly achieve a uniform product, even if the liquids you’re mixing have different thicknesses.

- It’s also great for making emulsions, which are mixtures of liquids that don’t normally mix well together. The mixer can make very small particles, between 0.6 and 4.9 microns in size.

- It can be grind both solid and semi-solid materials. It can turn them into a solution or a fine suspension.

- It is very helpful for making gel. For example, if you need to dissolve and spread substances like gums, alginates, CMC (carboxymethyl cellulose), carbopols, and more, the mixer can do it really fast. It will give you a solution without any lumps in just a few minutes.

Advantages of Silverson Mixer:

- It is very fast and can reduce mixing times by up to 90%.

- Silverton l5m can pump and mix materials on its own, without needing extra equipment.

- It gives a well-mixed solution without any air bubbles.

- It can create small droplets or particles, usually between 0.6 and 4.9 microns in size.

- It is time-saving and very cost-effective.

- With the help of a homogenizer, it can produce fast results.

Limitations of Silverson Emulsifier Mixer

- it requires the feed to be premixed and have a uniform and fine globule or particle size. This means that before using the mixer, the ingredients need to be already mixed together and in small, consistent sizes.

- It can cause the mesh clogging problem because the mixer uses a mesh or screen in its operation, and if the feed contains particles or materials that can clog the mesh.

- It consumes more power.

Read More: Propellers

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].