Turbine Mixture is the most common equipment that is used in various industries for mixing purposes. It is very effective in the mixing of highly viscous materials. In this article, you will learn in detail about their principle, working, construction, application, advantage, and disadvantages.

Principle of Turbine Mixer

The principle of Turbine Mixer works on the principle of Shearing

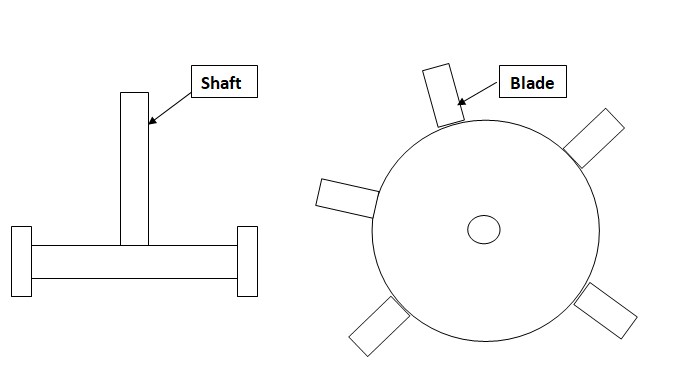

Construction of Turbine Mixer

A Turbine consists of a circular disc to which a number of short blades are attached. The diameter of the turbine ranges from 30 to 50% of the diameter of the vessels. It rotates at a lower speed about 50 200 RPM. The blades may be straight, curved, pitched, or verticle.

The Construction of Turbine Mixture equipt with the following types of blades:

Flat or straight blade Turbine: The flow in these types of blades is both radial and tangential components, with radial flow becoming dominant at higher speed.

Pitched blade turbines: Pitched blade turbines primarily produce axial flow. The impeller zone of rapid currents near the blades leads to high turbulence and intense shear.

Curved Blade Turbine: Curved blades help enhance fluid movement by directing the flow in a particular direction, enabling effective mixing.

Working of Turbine Mixer

The Working of the Turbine Mixer involves, the liquid being mixed is placed into the vessel, then further turbines are placed into vessels and start the rotation. After a certain time period when liquid is mixed, removed from the vessels.

Related: Sigma Blade Mixer for Mixing

Usage:

- It is effective for high viscous solutions up to 7000 pascals per second.

- It is used to mix slurries with 60% solids

Advantages of Turbine Mixers

Turbine mixers have several advantages as below:

- Turbines are known for generating higher shearing forces than Propellers, even at low pumping rates, resulting in a good emulsification process.

- Turbines are suitable for dispersion preparation.

- Blades in the tank, turbine mixers can handle liquids of large volume and high viscosity.

- It is very effective in In eliminating any stagnant zones.

- They required less space to install.

Disadvantages of Turbine Mixers

Turbine mixers have some disadvantages as below:

- Turbine mixers are not recommended for solvents with high viscosity, especially above 20 cP.

- Chace of air entrapment is high.

Conclusion:

In conclusion, turbine mixers provide an effective way to mix fluid materials. Its design is very compact to ensure well mixing by using different types of blades.

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].