1.0 Purpose: To lay down the procedure for cleaning & operation of peristaltic pump.

2.0 Aim: This Standard Operating Procedure applies to the peristaltic pump on the production floor.

3.0 Responsibility:

3.1 The trained Line Coordinator will be responsible for the operation of the peristaltic pump.

3.2 Officers / Sr. officers will supervise the process.

3.3 Production Manager will be responsible for the implementation of SOP.

3.4 Head-Quality Assurance will be responsible for compliance with SOP.

4.0 Safety Considerations:

4.1 Operating staff should be familiar with the maintenance and safety regulations applied for the built-in vendor components and cleaning & operation of peristaltic pumps.

4.2 Turn off the equipment while carrying out maintenance work.

5.0 Equipment:

5.1 Peristaltic Pump

6.0 Materials and reagents:

6.1 Filtered 70 % IPA.

7.0 Preparation of solutions:

7.1 Disinfectant solution to be prepared as per “Sanitization Solution Preparation” SOP.

8.0 Procedure on Peristaltic Pump:

8.1 Cleaning of peristaltic pump:

8.1.1 Put the power switch off and disconnect the power supply.

8.1.2 Clean the pump drive & pump head using a lint-free duster.

8.1.3 Mop the pump head with filtered 70% IPA by using a lint-free duster.

8.1.4 Allow the cleaner parts to dry for a while before switching on the peristaltic pump.

8.2 Frequency of cleaning:

8.2.1 Clean the equipment Before and after use.

8.3 Operation of peristaltic pump:

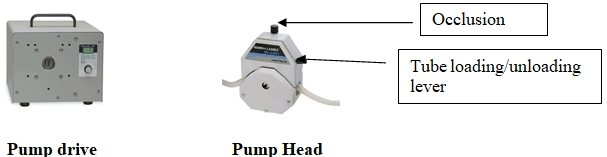

8.3.1 The equipment consists of a Pump drive & pump head.

8.3.2 Keep the pump drive in off condition.

8.3.3 Mount the pump head on the pump drive using a mounting bolt, as shown in the figure above.

8.3.4 Display on pump drive shows the following functions.

8.3.5 Open the pump head by moving the lever to the left.

8.3.6 Load the correct size tubing.

8.3.7 Move the lever to the right to close the pump head.

8.3.8 Connect to the main power supply to put ON the drive.

8.3.9 Select the internal or external operation by pressing the key ‘INT/EXT’ on the display panel.

8.3.10 Select the pump direction (clockwise/counter-clockwise) by pressing the key ‘DIR’.

8.3.11 Use the key ‘SPEED” to adjust the speed (Move the knob clockwise to increase the speed and anti-clockwise to decrease the speed) to achieve an appropriate flow rate.

8.3.12 Press Key ‘STOP/START’ to start or stop the pump.

9.0 Abbreviations:

PR: Production

ID No. : Identification number

No. : Number

QA: Quality Assurance

Rev.: Revision

SOP: Standard Operating Procedure

IPA: Iso Propyl Alcohol

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].