Standard Operation Procedure for Cleaning and Operation of Outside Micrometer in Pharmaceuticals.

Purpose: To lay down a procedure for cleaning & operation of Outside Micrometer.

Scope: This procedure is applicable for all Outside Micrometers used at our organization.

Responsibility:

- Department Head: Mention their responsibility here.

- Quality Assurance: Mention their responsibility here.

- Operators: Mention their responsibility here.

- Department Head: Mention their responsibility here.

- Maintenance Head: Mention their responsibility here.

Accountability: Quality Manager

Procedure:

- Instrument ID No.: Applicable on all Outside Micrometers (External Micrometer)

- Make: Mitutoyo

- Instrument Specification:

- Measurement Range: 0-25 mm

- Least Count: 0.01 mm

- Operating Temperature: 5°C to 40°C

- Storage Temperature: -10°C to 60°C

Definition:

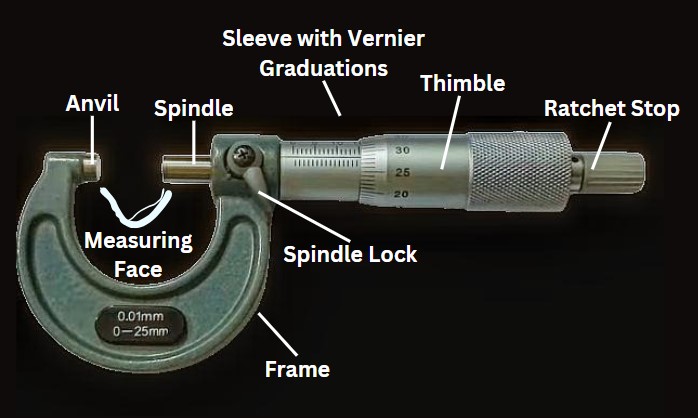

Outside Micrometer (External Micrometer): It accurately measures the outside diameter, length, and thickness of small objects. You know, it’s all about that precise distance between the spindle and the anvil when they just touch the sides of the object.

Primary Pointer: The zero mark on the thimble scale. When this lines up with the central reference line of the barrel scale, the distance between the anvil and the spindle is exactly an integral or a half-integral number of millimeters.

Frame: This part holds the anvil and spindle in a fixed position, keeping them aligned just right.

Anvil: It’s the fixed part where your object rests. When the spindle moves, it gently presses the object against the anvil.

Spindle: The spindle moves towards the object to hold it in place when you rotate the ratchet. It’s like a tiny arm giving a soft hug to your object!

Sleeve (Barreel): This is where you see the measurement, divided into 25mm sections with smaller subdivisions of 1/2 mm.

Thimble: This is the rotating part with the fine scale, and it’s what you turn to measure accurately.

Ratchet Stop: This nifty thing makes sure you don’t apply too much pressure. It stops the spindle when there’s just enough torque, preventing any damage or wrong readings. It’s also called the Constant-Force Device.

Clamp (Locking Lever or Lock Nut): This locks the spindle in place, so your reading stays spot on, even if you take the micrometer off the object.

Adjusting Wrench: It has two small protrusions to adjust the barrel and ratchet through tiny holes.

Lead Error: This is the difference between the real size of a gauge block and what you see during calibration. We always want to keep this error as small as possible.

Zero Point Alignment: This happens when the main pointer on the thimble scale lines up perfectly with the reference line on the barrel scale. You achieve this when you rotate the spindle until it gently touches the anvil.

Cleaning:

- Clean the external surface of the micrometer with the help of a lint-free dry cloth.

- Clean Up: First, wipe off any dust, chips, or moisture from the micrometer.

- Close it all the way with a piece of paper in between, then pull the paper out while cleaning the spindle and anvil.

Operation:

- Make sure both the micrometer and the object are at room temperature—this keeps everything accurate.

- Rotate the ratchet anticlockwise to open up space between the anvil and spindle.

- Place your object between them, then spin the ratchet clockwise until the spindle touches the object.

- Keep turning gently until you hear 3 clicks.

- Check that both the anvil and spindle are touching evenly.

- Set the lock nut while the micrometer is still on the object.

- Remove the object, then read the value from the barrel scale and the thimble scale.

- Add them up to get your total measurement.

- Unlock the nut and turn the ratchet slightly in a clockwise direction to close the micrometer before storing it.

Calibration:

- Calibration frequency: Once in a year

- Calibration of the micrometer shall be done from an External NABL accredited Laboratory.

Note: Calibration may be required before the plan in case of maintenance and damage to the

instrument. Also, master calibration plan should be based on process risk/ criticality of the products for which micrometer is used. The rationale should be available for defined frequency of calibration for micrometer.

Maintenance:

- Always look for any damages or marks that would suggest wear and tear.

- Make sure that the spindle and anvil tips are flat and do not have scratches.

- Rotate the thimble to its full range to make sure it is smooth or not.

- Perform a zero-point alignment test to ensure everything is aligned perfectly.

Precautions:

- The micrometer, as any instrument making measurements, should be kept at room temperature just like a heat-risked instrument. The other extreme is that the object under measurement must also be at room temperature for even the slightest change may interfere with the reading.

- Apply a little pressure on the micrometer while measuring the object! It’s mostly enforcing the clamp too much that causes an anvil, spindle, or even the object you’re measuring.

- Be sure to store the device in its place so that there is no excessive wear to the device. And one more thing, when you keep it, be careful that the anvil and the spindle don’t face off with each other. This way, the change in temperature will not put the instrument under pressure.

- It may be a good idea to measure the object quite a number of times to ensure that the reading obtained is accurate.

- The last point concerning operating the micrometer is to avoid sudden motions in the use of the micrometer, don’t drop the micrometer or hit it.

Records:

- Calibration Certificate

Distribution:

- Master document file

- Production

- Quality Assurance

- Quality Control

History:

| Sr. No. | Superseded | Effective date | Reason for change/revision |

Don’t Miss This…

- SOP for Monitoring and Recording Critical Environmental Parameters of Different classes

- SOP for Operating and Validating Anaerobic Systems

- SOP for Operating and Validating a Biosafety Cabinet

- SOP for Operating and Cleaning a Vortex Mixer in Microbiology

- SOP on Operation and Calibration of the Antibiotic Zone Reader

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].