1.0 Objective: To lay down a procedure for the destruction of rejected dies and punches.

2.0 Scope: This procedure is applicable to the destruction of rejected dies and punches used in the production department.

3.0 Responsibility:

Officer, Executive – Production Department

Manager – Production Department

4.0 Procedure:

4.1.1 Assemble all the defective punch sets, defective upper punches, lower punches, and dies that are to be discarded.

4.1.2 Deface the punches and dies to avoid misuse of the punches and dies.

4.1.3 Create a “Scrap Transfer Note” for each of these defective punches and dies, recording the information about each one in Annexure I.

4.1.4 With the use of a grinder, deface the punches and dies before moving them to the scrap yard for disposal.

4.1.5 Disposal work should only be done with the Head of Production, Head of Quality Assurance, and Unit Head’s consent and after taking all required safety procedures.

Note: Utilize a punch trolley to transfer the punches and dies from the storage room to the compression area. Punches must be kept in plastic sleeves for storage. Every year, the dial gauge and Standard Hobb should be calibrated.

5.0 Abbreviations:

QA: Quality Assurance

SOP: Standard Operating Procedure.

IOM: Inter Office Memo

6.0 Annexures:

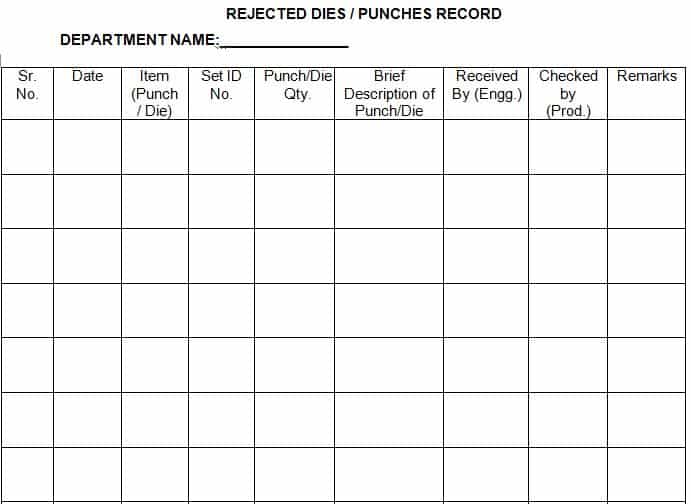

Annexure – I: Rejected punches / dies record

Related SOP: Indent, Inspection, and Maintenance of Punches and Dies

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].