1.0 Purpose: To describe the procedure for the transfer of semi packed material to warehouse.

2.0 Aim: This Standard Operating Procedure is applicable to the transfer of semi packed material from production to the warehouse.

3.0 Responsibility:

3.1 Officer Production

3.2 Head production

4.0 Safety considerations:

4.1 Always keep the PFS tubs/vials in an upright position.

4.2 Transfer the material immediately after receiving it from the filling area.

5.0 Procedure:

5.1 Transfer of filled Pre Filled Syringes:

5.1.1 Room shall be cleaned before transfer.

5.1.2 Receive the tubs containing Pre Filled Syringes through the dynamic pass box.

5.1.3 Check the packing and status label of the tub.

5.1.4 Put the sealed tubs in HDPE crates.

5.1.5 Place the lid on each crate.

5.1.6 Paste status labels on crates as per “status labeling” SOP.

5.1.7 Transfer the crates on pallets trucks and keep them in the dynamic pass box.

5.1.8 Intimate designated warehouse person to receive the material and keep it in a cold room for storage purposes.

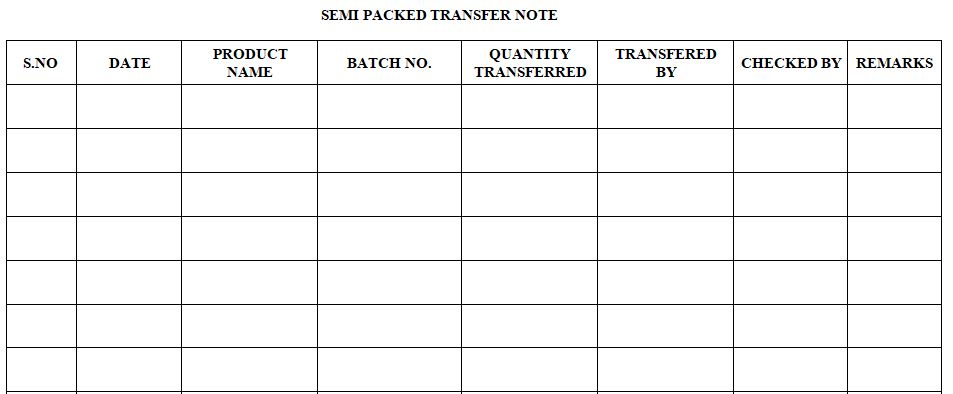

5.1.9 After completion of the batch sends the semi-packed transfer note to the warehouse with complete details as per annexure 1.

5.2 Transfer of filled Vials:

5.2.1 Area should be cleaned before transferring the filled vials.

5.2.2 Collect the vials from the turn table and placed them into the trays.

5.2.3 Paste status labels on trays.

5.2.4 Transfer the trays to the warehouse on pallets trucks and keep them in the dynamic pass box.

5.2.5 Intimate designated warehouse person to receive the material and keep it in a cold room.

5.2.6 After completion of the batch sends the semi-packed transfer note to the warehouse with complete details as per Annexure 1.

6.0 Abbreviations:

QC: Quality Control

QA: Quality Assurance

SOP: Standard Operating Procedure

DPB: Dynamic Pass Box

SPB: Static Pass Box

HDPE: High-Density Poly Ethylene

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].