1.0 Purpose: To lay down the procedure for operation and cleaning of glass, vial/ Syringes crushing machine, and handling of crushed material.

2.0 Aim: This Standard Operating Procedure is applicable for the operation and cleaning of glass crushing machines and handling of crushed material.

3.0 Responsibility: 3.1 Officer, and Executive – Production Department for implementation of this procedure.

3.2 Manager – Production Department for overall compliance with this procedure

3.3 Production Manager shall be responsible for the implementation of SOP.

4.0 Safety Considerations:

4.1 Wear safety equipment (Hand Gloves, Goggles, and masks) while handling the glass (vials/syringes) crushing machine.

4.2 Verify that the inlet and outlet valve of the water supply is correctly opened.

4.3 Avoid direct contact with the media vials while handling the process.

4.4 Check the ‘STATUS LABEL’ of glass material for crushing.

4.5 Do not start the motor directly when the filter (sieve) of the machine is open.

5.0 Procedure:

5.1 Operation and cleaning of glass crushing machine:

5.1.1 Ensure the machine is connected to 3-phase power on the main power button.

5.1.2 Ensure that the bolts of blades are properly tightened.

5.1.3 Check the water inlet supply ‘ON’.

5.1.4 Switch ‘ON’ green button of the motor.

5.1.5 Feed the material to be crushed in the hopper of the machine in the required quantity.

5.1.6 Check the revolution of the motor by detecting the rotation of blades towards the arrow.

5.1.7 If the rotation of blades is opposite from the arrow then change the phase of the connection.

5.1.8 Blades crush the glass material.

5.1.9 Collect the glass crushed material from the collecting bin.

5.1.10 Switch off the machine by the On/Off button and Off the main power supply and also Off the water supply.

5.1.11 Clean the machine by flushing a sufficient quantity of water throughout to remove any particles from inside the machine.

5.1.12 Clean the machine with 70% IPA (Prepare 70% IPA).

5.2 Handling of crushed material:

5.2.1 The scrap generated at the glass crushing machine shall be properly disposed of to avoid any misuse.

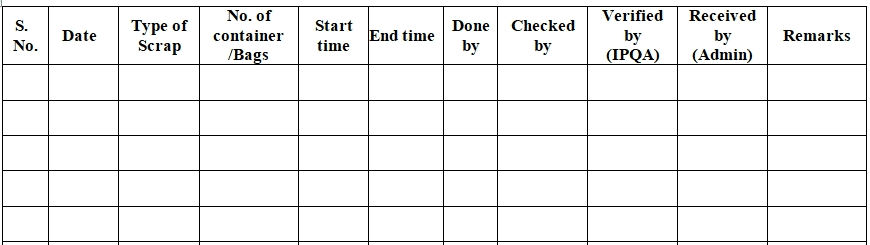

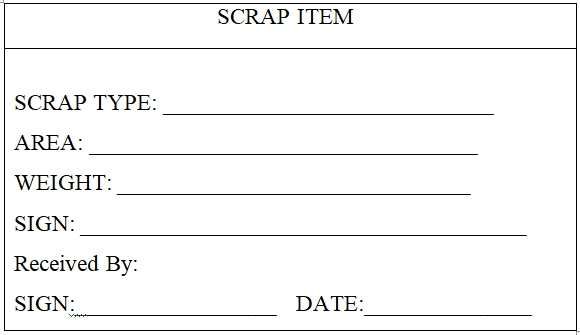

5.2.2 User department shall label the scrap as per Annexure-2 and record the details for all the scrap items in Annexure-1.

5.2.3 Before handover to the administration department, the supervisor of the concerned area shall examine the scrap item for the following:

5.2.3.1 Defacing of labels.

5.2.3.2 Absence of any usable material and product in the scrap item.

5.2.3.3 Proper Labeling of Material.

5.2.4 After verification of scrap, the personnel from the administration department shall weigh the disposed scrap and sign the label.

5.2.5 Finally, the administration department shall transfer all the segregated scrap items to the scrap yard.

5.2.6 logbook for the glass crushing machine should be filled after the completion of the process.

6.0 Abbreviations:

PFS: Pre-filled syringes

IPA: Isopropyl Alcohol

RPM: Rotation per minute

SOP: Standard operating procedure

GCM: Glass crushing machine

QA: Quality Assurance

IPQA: In-Process Quality Assurance

Admin: Administration department

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].