1.0 Objective: To lay down a procedure for polishing punches and dies.

2.0 Scope: This procedure is applicable to the polishing of punches and dies used in the production department.

3.0 Responsibility:

Officer, and Executive – Production Department for implementation of this procedure.

Manager – Production Department for overall compliance with this procedure.

4.0 Procedure:

4.1 Select the required brush as per the note given below

4.2 Use emery paper/bar to polish the tip of the punches for any inside burr.

4.3 Use cup shaped nylon brush and micro emery powder in case of concave punches with embossing.

4.4 Use a wheel-shaped nylon brush and micro emery powder in case of flat punches with embossing.

4.5 Use dome shaped felt bob and micro emery powder in case of concave and plain punches.

4.6 Use conical-shaped felt bob and micro emery powder in case of plain flat-faced beveled edged punches and dies.

4.7 Fix the required brush on the fixtures of the electrical grinder properly with the help of the key provided and tighten it properly.

4.8 Apply diamond paste/emery powder to the part to be polished as required.

4.9 Connect the electrical grinder to the mains and switch it ON.

4.10 Start the electrical grinder.

4.11 Bring the revolving polishing brush near the part to be polished. Touch it with the sides and polish it as required.

4.12 Fix the required brush on the fixtures of the electrical grinder properly with the help of the key provided and tighten it properly.

4.13 Clean the punches and dies using IPA after completion of polishing of punches.

4.14 Frequency: Polishing of the punches and dies to be done after the compression of twenty million tablets per set or every six months whichever is earlier.

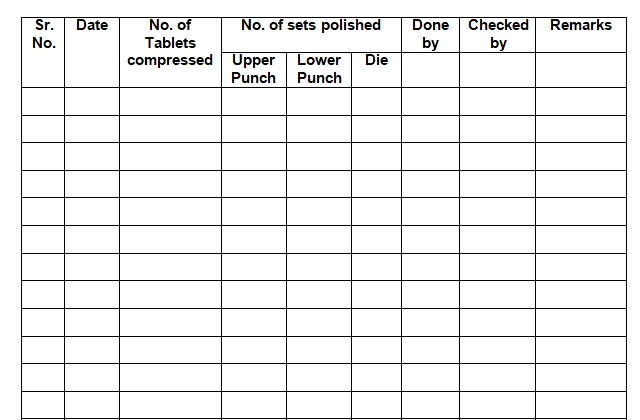

4.15 Record the polishing details in Annexure- I.

4.16 All the subsets of a particular set should be polished at a time.

Note: Polishing of punches and Dies is to be done in the compression spare room.

Frequency: After every six months or after compression of twenty million tablets per set whichever is earlier.

Related: SOP on Operation of Metal Detector

5.0 Abbreviation(S):

IPA: Iso Propyl Alcohol

SOP: Stander Operating Procedure

ANNEXURE -1 (PUNCH AND DIE POLISHING RECORD)

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].