| 1.0 | OBJECTIVE: |

| To lay down a procedure for the transfer of finished products to finished goods stores. | |

| 2.0 | SCOPE: |

| This procedure is applicable for the transfer of finished products to finished goods stores in the production department. | |

| 3.0 | RESPONSIBILITY: |

| Officer, Executive – Production Department Manager – Production Department In charge – Stores | |

| 4.0 | PROCEDURE: |

| 4.1 | After completion of packing, reconcile the quantity packed with respect to the quantity received from the manufacturing and stores. |

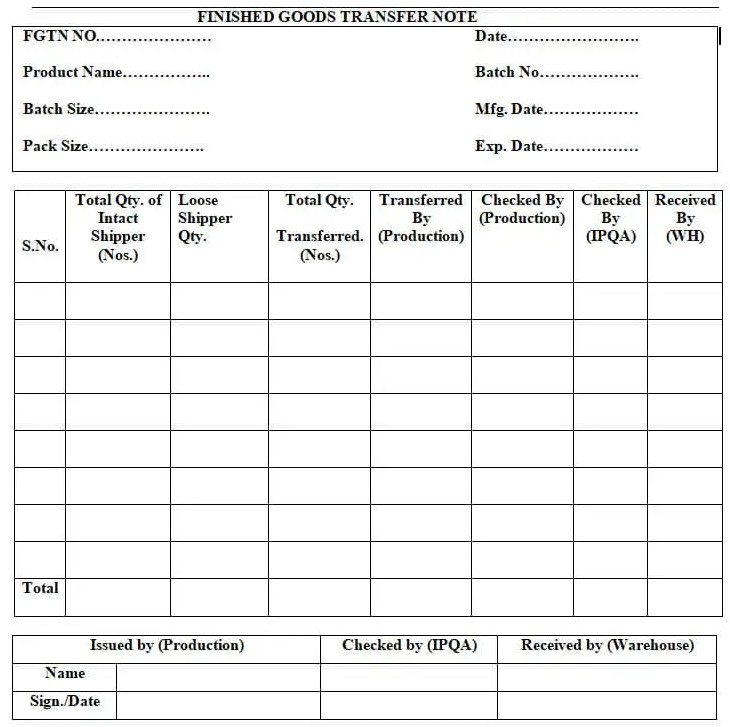

| 4.2 | Prepare finished goods transfer note in triplicate as per Annexure-II. |

| 4.3 | Label the last shipper of a batch as a ‘LOOSE BOX’ (if the quantity of packs is less than the quantity mentioned on the shipper label). Strike out the quantity preprinted on the shipper label and write the actual quantity and production officer and QA officer to sign on the label. |

| 4.4 | Intimate QA to verify the packed goods to be transferred to finished goods stores. |

| 4.5 | QA Officer must verify the quantity and shipper labeling of the finished drug product. |

| 4.6 | After verification from QA, the finished drug product is to be transferred to finished goods stores. |

| 4.7 | Stores Officer / In-charge must verify the quantity received on the transfer slip and transfer the same to finished goods stores. |

| 4.8 | Store Officer/ In charge is to endorse the transfer slip and return the book to the packing department. |

| 4.9 | Write the transfer slip no. in the respective BPR. |

| Note: The above procedure is also applicable at the end of day activity as per annexure-I. | |

| 5.0 | ABBREVIATION(S): |

| BPR: Batch Packing Record | |

| QA: Quality Assurance | |

| 6.0 | ANNEXURE(S): |

| Annexure-I: Daily production Report. | |

| Annexure-II: Finished Goods Transfer Note. |

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].