The Triple Roller Mill is a highly valuable equipment used in different industries for mixing purposes. It is known as Triple Roller Mill.

Principle:

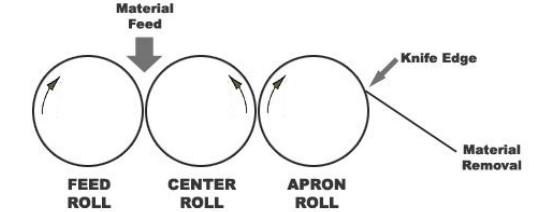

Principle of the Triple Roller Mill Operating on the principle of shear force, the three-roll mill contains three horizontally positioned rolls. These rolls rotate in opposite directions and at varying speeds relative to each other. This movement allows the mill to mix, refine, disperse, or homogenize viscous materials.

Related: Silverson Mixer

Construction:

The triple roller mill contains three rollers made from hard abrasion-resistant material. The rollers are separated by a minimum distance of 0.05 mm, and a maximum up to 0.3 mm. These rollers are arranged close to each other, ensuring optimal efficiency. Additionally, they are set to rotate at different speeds. When the material passes between the rollers, it undergoes crushing, upon the gap between them by using their respective rates of movement.

Working:

Working Mechanism of the Triple Roller Mill: As the material enters the hopper, it proceeds between rollers 1 and 2, while processing size reduction. The gap between rollers 2 and 3 is kept narrower than that between 1 and 2 with a rotation speed of 15 to 125 R.P.M. This helps in further crushing and smoothing the mixture, which adheres to roller two. To maintain the integrity of the final product, a scrapper is attached to remove the mixed material from roller number three. By doing so, it prevents any material that hasn’t passed between both sets of rollers from reaching the scrapper.

Advantages:

- Effective for squeezing & homogenizing cream, paste, and semisolids

- User friendly

- Corrosion-resistant, medical & food grade contact parts

Application:

Applications of the Triple Roller Mill includes the following:

- Dispersing materials within semi-viscous substances like cream.

- Effective in homogenization during the preparation of ointments, creams, pastes, doughs, and other viscous formulations.

- It helps in the mixing of pharmaceuticals, herbal and alternative medicines, chemicals, fine chemicals, food products, agriculture-related substances, cosmetics, detergents, and pigments.

Related: Paddles Mixture

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].