A vacuum dryer is an effective equipment used in many industries, for example, pharmaceuticals, food processing, plastics, and textiles. Inside this equipment, vacuum is used to dry materials that are heated at low temperatures to easily evaporate. In this article learn about Vacuum Dryer and their Principle, Construction, Working, Advantages, Disadvantages, and Usage

Principle of Vacuum Dryer:

A Vacuum dryer is used to dry materials by the application of vacuum. When a vacuum is created, the pressure is lowered so that water boils at a lower temperature. Hence, water evaporates faster. The heat transfer becomes efficient for example; the rate of drying enhances substantially.

Related Dryer: Spray Dryer

Construction of Vacuum Dryer:

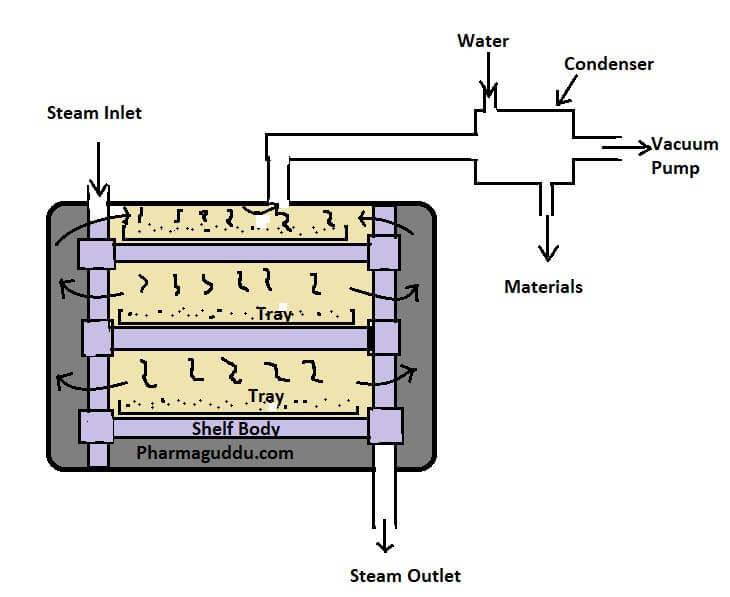

A vacuum dryer consists of a chamber divided into hollow trays or shelves, which increase the surface area for heat conduction. The oven door is designed to be airtight and connected to a vacuum pump to reduce the pressure inside. The material to be dried is placed on the trays inside the dryer, and the pressure is lowered using the vacuum pump. The oven is also connected to a condenser to collect the evaporated moisture.

Working of Vacuum Dryer:

- The material to be dried is placed on the trays or shelves inside the vacuum dryer and then reduced the pressure to a range of 30 to 60 KPa using the vacuum pump.

- Then close the oven door tightly and steam is passed through the jacket space and shelves, allowing for heat transfer through conduction.

- Under vacuum, the water in the material evaporates at temperatures of around 25-30°C.

- The vapor is then directed to the condenser.

- After drying, the vacuum line is disconnected, and the dried material is collected from the trays.

Advantages of Vacuum Dryer:

- Easy material handling.

- The hollow shelves can be electrically heated, providing a large surface area for efficient heat transfer.

- Hot water can be supplied through the dryer to allow drying at the set temperature.

- It is suitable for drying heat-sensitive materials without degradation.

Disadvantages of Vacuum Dryer:

- Batch process, limiting continuous production.

- Lower efficiency compared to some other drying methods.

- Higher cost and maintenance requirements.

- Risk of overheating due to the vacuum.

Uses:

- Drying heat-sensitive materials that undergo decomposition.

- It is able for Drying dusty and hygroscopic materials.

- It is easy for Separating drugs containing toxic solvents into closed containers.

- Effective in Recovering valuable solvents from feeds through condensation.

- Producing porous end products for certain drugs.

Conclusion:

Vacuum dryers are widely used in different industries for drying heat-sensitive materials. It uses a vacuum so it becomes easy to evaporate materials at low temperatures.

Related Post: Drum Dryer

FAQs:

Yes, vacuum dryers can easily handle drying dusty and hygroscopic materials, because the vacuum inside the chamber prevents moisture absorption and contamination.

It is useful for heat-sensitive materials, able to remove moisture at low temperatures, which helps in storing their quality.

Yes, it is useful to dry heat-sensitive materials which undergo decomposition at higher temperatures.

No, It is a batch-based process, where materials are loaded batch-wise.

Vacuum dryers operate at a higher cost because of vacuum usage, although it required less heat to get dried materials.

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].