Water is widely used in pharmaceuticals as an ingredient, solvent for processing, analytical reagents, and Manufacturing of pharmaceutical products. So, according to pharmacopeia, different types of water are recommended as per the official book and chapter <1231>.

Note: Information in this Article doesn’t change the existing guidelines and regulations. It helps users to understand or cover pharmaceutical water usage. for more information read USP chapter <1231>.

The different types of water grades and their use in the manufacturing process are described below.

Types of Water in pharmaceuticals according to USP

- Drinking or Potable water

- Purified Water

- Water for injection (WFI)

- Sterile Water for injection(SWFI)

- Bacteriostatic Water for injection

- Water for hemodialysis

- Sterile Water for irrigation

- Sterile Water for inhalation

- Water for analytical purposes

1. Drinking or Potable water

Drinking water in pharmaceuticals shall comply with the standard specified by the Bureau of the Indian standard of WHO, Drinking water standard, and US potable water standard 40 CFR 141. Indian pharmacopeia has given a 500 CFU/ml limit for the total aerobic microbial count for drinking potable Water.

Purposes of Drinking water:

- For use as a drinking water

- Preparation of external use products

- Washing and extraction of crude drugs

2. Purified Water:

Purified Water Means Water intended for human consumption and may be sealed in bottles and other containers with no added ingredients.

It is used as a recipient in the production of non-parenteral preparation and other purposes, such as cleaning certain equipment and non-parenteral products.

Purified water is prepared by distillation, ion exchange, or any other appropriate means from suitable potable Water.

The purification process shall comply with standards given in monographs of official books and pharmacopeia. The limit for the microbial population for purified Water is 100 CFU\ml. Pathogen shall be absent in purified Water.

Difference between Purified Water and Potable Water

Purified Water: Pure Water contains no minerals or side chemicals. It is pure H₂O and only contains Hydrogen and Oxygen. Pure Water has been mechanically filtered to remove all impurities and make it suitable for use. Distilled Water is the most common type of purified water.

Purified Water is often employed in preparation, drinking, scientific studies, and laboratories. Nowadays, Water is frequently purified by processes like capacitive deionization, carbon filtering, reverse osmosis, micro-filtration, ultra-filtration, and ultraviolet oxidation.

Potable Water: Potable Water is Water that is fit for consumption by human beings and other animals. It is also called drinking water. It is safe for drinking and food preparation, without the risks of health problems. Water that is contaminated is often treated to turn it into potable water.

One of the easiest ways to treat water is by heating it to a boil. Boiling the Water might not remove heavy contaminants, but it can neutralize most bacteria and viruses that can be present.

3. Water for injection (WFI)

Water for injection (WFI) is a part of the purified water system in pharmaceuticals. WFI is used as an excipient in the production of the parenteral product and controls the product endotoxin and other preparation while water is used as a vehicle, and also used to clean the parenteral product containers.

The pH of Water for injection ranges from 5.0 to 7.0

Use of Water for injection

- For the production of parenteral products to protect from microbial growth or contamination.

- For cleaning purposes of contact part components in parenteral products.

Preparation Technique of Water for injection

Water for injection is prepared by Distillation of potable Water or Purified Water, Reverse osmosis, and Membrane process.

Storage of Water of injection (WFI)

The first portion of the distillate is discarded, and the remaining is collected and stored in a special tank containing ultraviolet lamps or in a sealed container. It can be stored for a period of up to a month.

Difference between purified Water and WFI

Water for injection is highly purified as it is condensed and kept at 80-90 degrees Celcius to maintain its properties. It is stored in a single dose for IV administration purposes after adding the required amount of solute. In contrast, purified Water is kept at room temperature.

4. Sterile water for injection (SWFI)

When combined with a suitable solute, sterile, non-pyrogenic, distilled water is packaged in a single-dose container for intravenous administration. Additionally, it can be used as a dispenser for diluent. The absence of any additives, including antimicrobials,

It should be packed only in a single dose container, not larger than a 1-liter size. It should comply with the standards given in the monograph of official books or pharmacopeias.

The recommended microbial limit is not more than 10 CFU per 100 ml, and the pathogen should be absent.

For both WFI and SWFI, the total organic carbon (TOC) as per IP is not more than 0.5 mg/ liter. In contrast, the same limit of TOC for Water (500 PPB) in USP and BP.

Preparation Technique for SWFI

Sterile Water for injection is prepared By distillation of Water.

Use of sterile Water for injection

It is intended mainly for use as a solvent for parenteral preparation, such as powder for injection. It is distributed as dry because of the limited solubility of its solution.

5. Bacteriostatic Water for injection

It is the sterile injection of water that has two or more suitable antimicrobial preservatives added to it

It is used in parenteral products as a diluent, mainly for multi-dosage products requiring continuous content withdrawal. It should be packed in not larger than 30 ml containers either in a single dosage or multi-dosage.

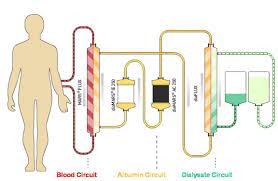

6. Water for Hemodialysis:

Water for hemodialysis is used as a diluent for hemodialysis concentrate solution. It is produced by EPA (regulatory agency for regulating drinking water to protect public health), purified Water treated to prevent microbiological and chemical attacks. This Water is not intended for injection. It shall be stored in an unreactive container to avoid microbial attack.

7. Sterile water for irrigation

Sterile Water for irrigation is Water for injection that is packaged and sterilized in single-dose containers. Sterile Water for irrigation can be stored in Container sizes larger than 1 liter. It allows quick delivery of contents and it’s not mandatory to meet the requirements for small-volume injections.

It is used for applications that don’t have particulate specifications or wherever pure Water or Water for injection is indicated. However, access to a good water system is absent, or larger quantities of Sterile Water for injection are required.

8. Sterile Water for inhalation

Sterile Water for inhalation is Water for injection, which is packaged and sterilized. It is employed in inhalators and the preparation of inhalation solutions.

It is not suitable for parenteral applications because it carries less stringent specifications for bacterial endotoxins than Sterile Water for injection.

9. Water for analytical purposes:

Distilled Water, freshly distilled Water, Deionized Water, high-purity water, and Carbon dioxide-free water are incorporated for Analytical purposes.

Uses Benefits of Water in Pharmaceutical

Water may present as an excipient, or it may be used to reconstitute products during synthesis, during the production of the finished product, and as a clinic agent for rinsing equipment, primary packing materials, and vessels.

Conclusion:

Water in pharmaceutical topics concluded that Water for pharmaceutical management is a critical part of the pharmaceutical manufacturer throughout the operation.

It should also be noted that stainless steel tanks for decalcified and purified Water can be sterilized regularly through clean steam.

Therefore, validation of the system will ensure the production of Water will be dependable and within the specified limits. In this case, it will be easy to prove that the price of the purified Water will be competitive and, in practice, less expensive than another water-producing system.

Frequently Asked Questions (FAQ)

Ans: USP Chapter <1231>

Ans: USP Non-Monographed water includes Drinking water, Hot purified water, Distilled water, Deionized water, Deionized Distilled water, filtered water, ammonia, oxygen, lead-free water, Deaerated water, LAL reagent water, and hot water.

Ans: Calcium and Magnesium

Ans: The water system should be observed frequently enough to make sure it is under control and continuing to produce water of a good standard.

Ans: Sterile water for Injection

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].