Air Separator is a pneumatic device that sperate the materials based on their size with the help of air current. This sperate the materials of lighter density from those of greater density and smaller size particles from the bigger ones.

Air Separator Principle:

The air separator operates based on a similar principle as the cyclone separator. But in Air separator, as the name suggests (Particle separation using Air) Air movement is obtained by using rotating discs and blades. To enhance the separation process, stationary blades are incorporated. By adjusting the blades and controlling the rotational speed, the separator enables variable separation at different sizes.

Construction:

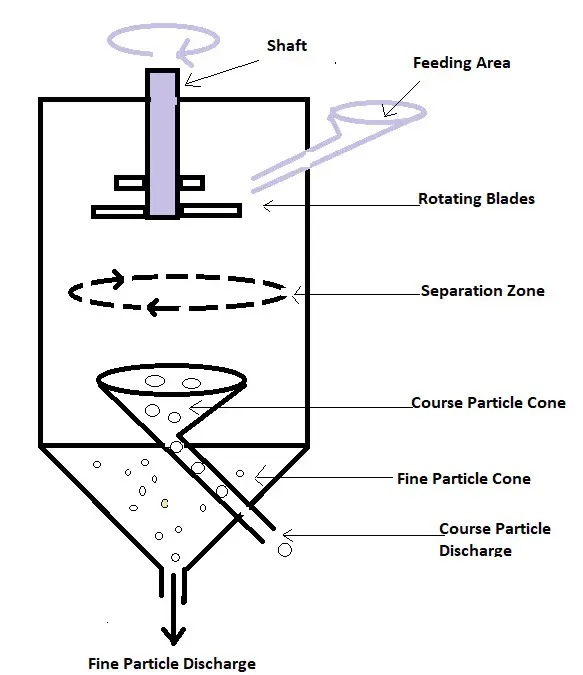

It has two compartments a cylindrical vessel and below is a conical base, the air separator contains a feed inlet at its upper part. On the Base side, it includes two outlets at the base, one for light particles and another for heavy particles. The central shaft supports the rotating disc and blades, generating the necessary air movement.

Working:

Firstly, the powder material is passed through the feed inlet, It will fall onto the rotating disc. Both the rotating disc and blades are attached to the same shaft. It will facilitate the production of an air current as indicated by the arrows in the above figure. The fine particles go into the area where air velocity is less. Later, these fine particles start to collect in fine particle cones. Finally, they pass through the fine particle discharge area. On the other hand, the heavy particles pass from the course particle cone.

Air Separator Uses:

- Often attached to ball mills or hammer mills

- Separates and returns oversized particles for further size reduction

Advantages:

- Enhances efficiency and precision of particle separation

- Enables adjustment of separation size for specific requirements

- Promotes thorough separation even for challenging materials

- Compact design allows easy integration into existing production lines

- Robust construction ensures durability and minimal maintenance.

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].