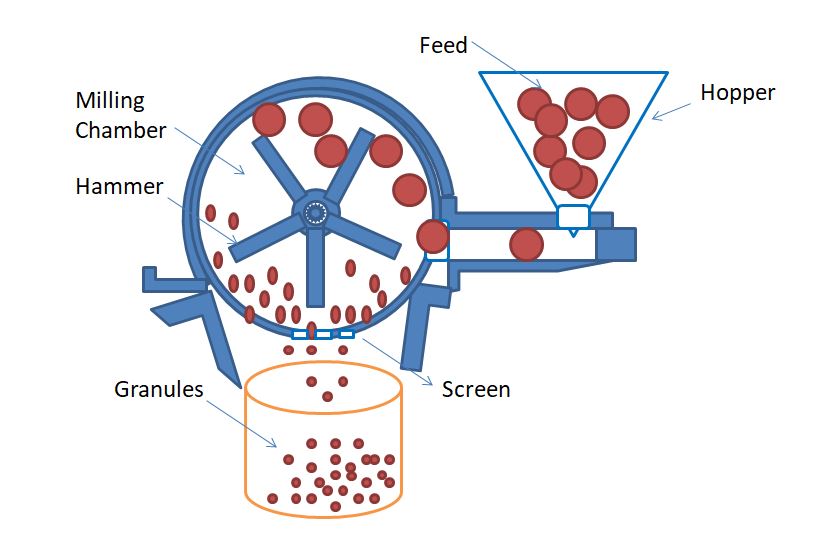

A Hammer Mill machine is widely used in the Pharmaceuticals and Food industries to cutting Materials into small fragments or small pieces (Also called Size Reduction). The main component of a hammer mill is a row of hammers that are hinged on a central shaft and contained in a strong metal container. Size reduction is achieved by Impact.

Usage of Hammer Machine

Hammer mill is used in the Pharmaceuticals, Food beverage, and Cosmetic industries to Reduce material particle size.

Working Principle:

The principle of the Hammer mill is based on the Impact between a rapidly moving hammer mounted on the rotor and powder material.

Construction:

- Hammers are made up of stainless steel (316L for material contact parts and 304 for non-contact parts).

- A Hammer mill is essentially a steel drum or milling chamber containing a verticle or horizontally rotating shaft.

- Hammer contains 4 to 5 small size hammer

- The lower part of the hammer mill consists of a screen through which material can pass after desirable size reduction.

- Finally, after desirable size reduction material passes through the duct screen to collect in a container.

Working

- Feed the material into the hammer mill through the hopper and press the start button.

- The Hammar assembly starts to rotate (with 8000 to 15000 RPM speed), and particle size reduces into small particles due to dynamic impact.

- After the reduction of particles falling within the container through the screen.

Types of Hammer mill Machines

Hammer mills are of two types, Horizontal shaft (Moves horizontally)and verticle shaft (Moves Vertically) types. They differ only by moving conditions, although the remaining things are the same.

Types of Hammer

Hammers are of two types, Stirrup and Bar shaped. Bar shape hammers are used extensively in tablet granulation.

Read Also: Colloidal mill; Working and Principle

Advantages

- It produced rapid action in grinding

- Hammer also useful for hard particles

- East and Fast to use

- Required less space and is easy to dismantle, and clean.

Disadvantages

- Produced more sound.

- Be careful to use heat-sensitive materials because the hammer produced more heat.

- Can’t be used to grind fiber materials.

FAQs

impact

Stress is need to apply in the hammer to crush the powder and it is usually applied between the hammer and feed

Bar shape is used in tablets granulation processing

Hammer is made of stainless steel

Particle size in the hammer mill depends on the feed rate.

Factors including no. of hammer, rotor speed, and size of the screen are used.

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].