A Ball Mill is used to grind the materials to get a course or fine powder. Ball mill is also known as the tumbling mill and pebble mill.

Principle

Ball mill principle work on Impact and Attrition. Both are responsible for size reduction, rapidly moving balls are used for reducing the size of brittle materials.

Impact: Impact mean pressure exerted by two heavy objects.

Attrition: Reduced the size of the materials when they colloid by heavy weight (Ball).

Construction:

The ball mill grinder consists following Parts:

Cylinder: cylinder is made of a hollow metal that moves about its horizontal axis. the cylinder can be made of porcelain, metal, and rubber. the length of the cylinder slightly higher than its diameter.

Ball: The ball lies in cylinders, which are made up of stainless steel, the size of the ball depends on the cylinder diameter. The ball covers 30 to 50% area in the cylinder.

Working:

- Open the lid and Feed the materials into the cylinder

- Introduced the fixed numbers of balls and closed the lid

- Run the machine and adjust the speed as per required.

- After achieving the desired particle size, stop the machine and remove the materials.

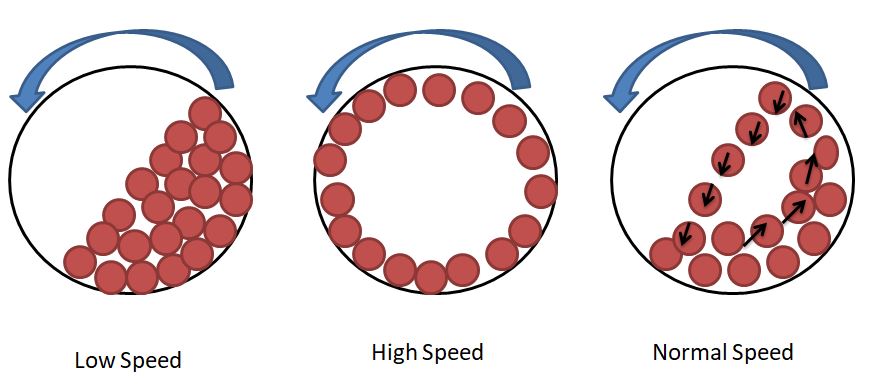

Ball mill Speed Impact on Size Reduction

Low speed: At low speed, the mass of balls will slide or roll up one over another and will not produce a significant amount of size reduction.

High Speed: At high-speed balls are thrown to the cylinder wall due to centrifugal force and no grinding will occur.

Normal speed: At Normal speed balls are carried almost to the top of the mill and then fall into a cascade across the diameter of the mill, in this way maximum size reduction is obtained.

Related: Hammer Mill

Ball mill usage in Pharmaceuticals:

It is used in reducing the size of the drug.

Advantage:

- Minimum loss of materials

- suitable for the wet and dry grinding process

- Sterility can be maintained due to a close container system, hence useful in the manufacturing of parenteral and ophthalmic products.

- Particles size is easy to reduce

- Less energy consumed

- Easy to clean

- Required less space to install

- low maintenance cost

Disadvantage:

- It is a slow process

- Produced strong vibration and sound and less in case of rubber ball usage.

- Can not reduce soft, tacky, and fibers materials

- Wear occurs inside the cylinders hence chances of possible contamination are high

- Less capacity, do not handle the large quantity.

Ball Mill Price

Ball Mill Price in India ranges from 53,000 to 1.20 Lac depends on the size.

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].