Why is HPAC Mobile phase Degassing done? When different liquids mix in HPLC analysis, bubbles forming can cause problems. To avoid this, we removed the bubbles by degassing the liquid used in the analysis.

Unstable and Noisy Baselines

Lower flow rate precision of pump due to cavitation in piston chamber or effect on check valve performance. Excessive pressure can develop which can lead to eventual pump failure.

When air bubbles go through the detectors, they make false peaks show up. These bubbles can make the liquid move strangely through the HPLC tube, creating empty spaces that mess things up.

Before a discussion on the features of degassing techniques let’s understand how the problem arises. Solvents equilibrate with atmospheric gases on exposure to the laboratory environment. On mixing the solvents the solubility of air is less than it is in the same proportion of pure solvents and excess air will tend to bubble out.

When liquids mix or when there are rough surfaces in the system, bubbles might form. You don’t have to get rid of all the air in the liquid, just a bit to reduce it below a certain level. Systems that mix at low pressure tend to make more bubbles. With low-pressure mixing, the liquids are blended at regular air pressure, and bubbles can form anywhere along the flow.

However, with high-pressure mixing, the liquids are mixed after going through pumps and are blended in a high-pressure chamber. Even if the mixture is full, the high pressure stops bubbles from forming. If there are any bubbles, they might show up when the liquid comes out of the column and goes back to normal air pressure.

HPLC Degassing Techniques

Commonly used degassing practices for the HPLC mobile phase are:

- Helium purging

- Vacuum degassing

- Sonication

Heating is the best way to completely remove air from a liquid, but it’s not recommended because it can make some important parts disappear along with the air. Also, it takes a long time to make the liquid at the right temperature.

1. Helium Pursing:

Using helium can remove about 80% of the air in the liquid. For a mix of water and certain chemicals, using the same amount of helium as the liquid works well. But it’s important not to use too much helium because it can make some of the important liquid parts disappear.

2. Vacuum degassing:

Vacuum degassing can take out more than 60% of the air. One way is to use a special filter while pulling the liquid through it with a vacuum. Many commercial systems have a way to do this while the liquid is still in the machine. The special tubing inside removes the air but keeps the liquid inside.

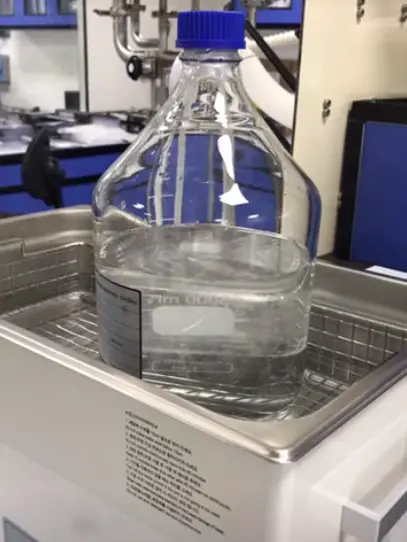

3. Sonication:

Using ultrasonic baths to sonicate substances is quite common in labs. However, when used alone, it can only eliminate around 30% of the air dissolved in the liquid. It’s better to combine sonication with other techniques for better results.

For practical reasons, it’s wise to remove air from the mobile phase in both low and high-pressure mixing setups. Combining different methods helps a lot in solving issues caused by bubbles forming in the liquid.

Many systems available for purchase come with on-line vacuum degassing. When you use sonication alongside this on-line degassing, you can achieve good outcomes.