OBJECTIVE: To lay down a procedure for HPLC Column Cleaning and their Maintenance.

SCOPE: This Standard operating procedure shall be applicable to HPLC Column Cleaning and maintenance of different types of HPLC columns used in the Quality Control Laboratory.

RESPONSIBILITY:

Officer/Execution QC department to follow this procedure.

Manager QC department for overall compliance with this SOP.

PROCEDURE for HPLC Column Cleaning and Maintenance:

Receipt and Inspection of New Column:

- Upon receiving a new column, carefully cross-check it with the provided index.

- Inspect the column for any physical damages that may have occurred during transportation.

- Verify that the column’s make, type, serial number, dimensions, and other specifications align with the certificate of analysis from the supplier.

- Ensure compatibility between the column and the instrument fittings. If any non-compliance with user requirements is found, return the column to the supplier.

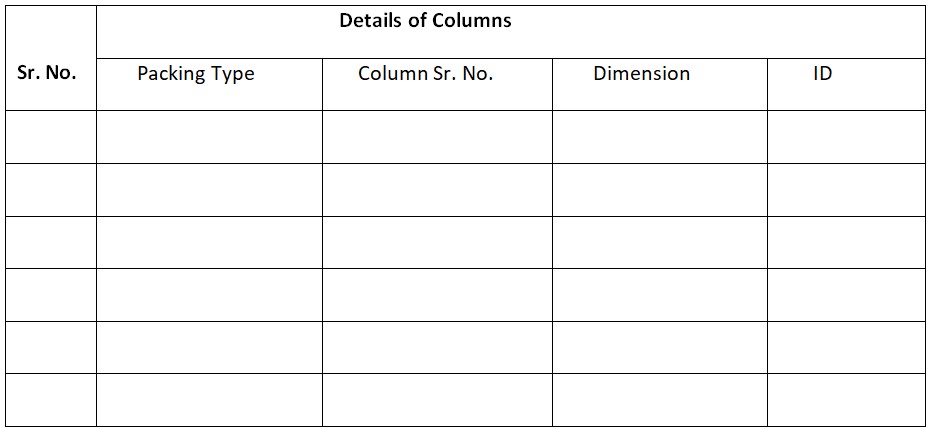

- If the column meets user requirements, record its details in Annexure-1 and assign the column ID as per LC, C, YYY, where LC stands for Liquid Chromatography, C stands for the column, and YYY represents the serial number starting from 001.

Issuance and Performance of Column:

- Issue the column as per the requirements stated in the standard test procedure of the specific product.

- Before use, test the column to ensure it meets the system suitability criteria for the intended product.

- If the column satisfies the system suitability criteria, proceed with further analysis.

- If the column fails to meet the criteria, return it to the concerned person for testing on another product.

- In case of repeated failure to meet the system suitability parameters, return the column to the supplier.

Column Regeneration for Reverse Phase Column:

- Flush the column using warm water (55°C) at a flow rate of 0.7 ml/min for 10 minutes, maintaining the column at (55°C) in the column oven during flushing.

- Inject 100 ul of DMSO four times with a 2-minute interval between injections.

- Follow with water flushing for at least 30 minutes and methanol flushing at a flow rate of 0.7 ml/min in the reverse direction for 60 minutes.

- Conclude the regeneration process by flushing the column with chloroform for 60 minutes at a flow rate of 0.7 ml/min in the reverse direction.

- Subsequently, wash the column in methanol for 60 minutes at a flow rate of 0.7 ml/min in the reverse direction.

- Perform the suitability system test after regeneration following the STP for the Related product.

- Store the column in methanol after flushing the column and store in methanol for 20 minutes at a flow rate of 1.0 ml/min in the normal direction.

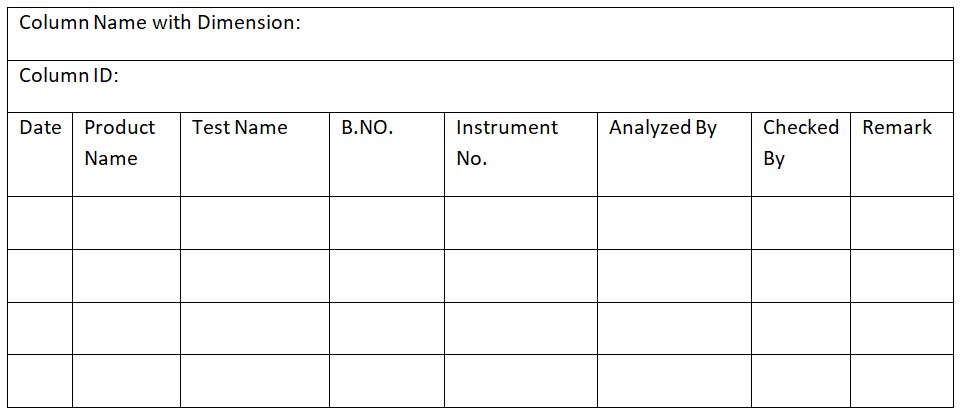

- Record the column regeneration details in the column history Record card.

Column Regeneration for Normal Phase Column:

- Use the Hexane to wash the column for 60 minutes at a flow rate of 2.0 ml/min.

- Continue with Methylene chloride washing for 60 minutes at a flow rate of 2.0 ml/min.

- Wash it Followed by IPA washing for 60 minutes at a flow rate of 2.0 ml/min.

- Conclude the regeneration process with methanol flushing for 60 minutes at a flow rate of 2.0 ml/min.

- After regeneration, conduct the system suitability test as per the standard test procedure for the relevant product.

- Store the column in Hexane after flushing it for 20 minutes at a flow rate of 2.0 ml/min in the normal direction.

- Record the column regeneration details for future reference.

Related: Calibration of HPLC and their Operation SOP

Storage condition for HPLC Column in solvent:

| Column Type | Storage Solvent |

| Reverse-phase silica gel | Watery Methanol, Chloroform, Methanol |

| Normal-phase silica gel | 2-Propanol, Chloroform (with 2% 2,2-Dimethoxypropane and 1% Acetic anhydride), Chloroform, n-Hexane |

| Chemically modified packing agent | Methanol, Chloroform, n-Hexane (for reverse-phase system) or Watery Methanol, Chloroform, Methanol (for normal-phase system) |

| Ion-exchange silica gel | Water, 0.1 M EDTA•2Na, Water Methanol, Water (with the amount of each washing solvent being about 10 times the column volume) |

Withdrawal of Column:

Columns may be withdrawn from further analysis in the following cases:

- When physical damage is detected.

- If the column fails to comply with the system suitability requirements after regeneration.

HPLC Column Cleaning/ Washing Procedure:

Washing of C18, C8, C6, Phenyl, CN, Amine-Reverse Phase Columns:

- For mobile phases containing a buffer, follow this washing procedure with a flow rate of 1 ml/min:

- Water for 15 minutes

- Water + ACN (50:50) for 15 minutes

- Methanol (100%) or the solvent used in the mobile phase preparation for the analysis, for 15 minutes.

- After washing, disconnect the column from the HPLC unit and store it in the designated area.

- For mobile phases without buffer (salts), use the solvent used for the mobile phase preparation during analysis with a flow rate of 1 ml/min for 30 minutes (e.g., Acetonitrile if used in the mobile phase).

- Again, disconnect the column from the HPLC unit and store it properly.

Washing of Protein Pack Column:

- Wash the column with a minimum of 30 ml of 2.5 M acetic acid.

- Disconnect the column from the HPLC unit and store it appropriately.

Washing of 117 Columns:

- Change the mobile phase to a mixture of 0.01 N H2SO4: ACN in a ratio of 85:15 v/v and flush at a flow rate of 1.0 ml/min for a minimum of 2 hours.

- Flush the column with water at a flow rate of 1.0 ml/min for 2 hours.

- Disconnect the column from the HPLC unit and store it as required.

Washing of Silica or Silica bonded-Normal Phase Columns:

- Wash the column with the mobile phase (Non-polar) used for analysis, or use non-polar solvents like Hexane and Heptane for washing.

- Flush the column for 30 minutes at a flow rate of 1 ml/min.

- Disconnect the column from the HPLC unit and store it appropriately.

- Maintain records of column washing (post-use) in the column usage log.

Important Cautions:

- Properly washing the column after each use is necessary to avoid poor peak shapes, non-reproducible retention times, high back pressures, and baseline disturbances.

- Avoid the use of harsh reagents, as they can damage the bonded phase of columns.

- Prevent column contamination by using filtered and degassed mobile phases, as well as filtered samples and standards during analysis.

- To prevent void formation, place the columns in an area free from vibrations, which could cause mechanical shocks.

- Gradually increase the flow rate when flushing the column.

- Filter water with a 0.45-micron filter paper.

- By adhering to these best practices, you can ensure the optimal performance and longevity of your HPLC columns in various analytical applications.

ABBREVIATION

SOP: Standard Operating Procedure

No.: Number

Dept.: Department

ml: Millilitre

min: Minute

°C: Degree centigrade

IPA: Isopropyl Alcohol

DMSO: Dimethylsulfoxide

ID: Identification number

ACN: Acetonitrile

H2SO4: Sulphuric acid

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].