Here You will learn about Standard Operating Procedure for Operating and Cleaning of Dry Bath Incubator including their Purpose, Scope, Responsibilities, Procedure, Cleaning, Precautions, maintenance, and Various Records.

Purpose: To establish a standard operating procedure for operating and cleaning of Dry Bath

Incubator used in Laboratory. To meet compliance with Good Laboratory Practices.

Scope: This standard operating procedure is applicable for operating and cleaning of Dry Bath Incubator used in the Laboratory.

Responsibility:

- Department Head responsible for preparation and implementation of this procedure.

- Quality Assurance personnel is responsible for review, control, approval, and release of this procedure.

- Laboratory personnel are responsible for operating the machine according to this procedure and to inform department head of any breakdown in the Dry Bath Incubator.

- Laboratory personnel responsible for preparation of Dry Bath Incubator-related records.

- Maintenance Head: Write responsibility here.

Accountability:

- Quality Manager

Procedure:

- Instrument Introduction:

- Instrument Name: Dry Bath Incubator

- Instrument ID No.: Mention ID number as per your internal procedure.

- Model No.: Mention your model number.

- Electricity Requirement: Mention electricity requirements from instrument Manual.

- Manufacturer: Mention manufacturer name of instrument.

Cleaning:

- Clean the surface of the Incubator including shelves with help of lint-free cloth soaked in Collin, Dettol, or 70% IPA solution.

Operation of Machine:

- Place the equipment in a convenient place.

- Now, Connect and do the Incubator setting to 230V+10, Single phase, 50 Hz, AC supply.

- Switch on the main ON/OFF switch on the control panel.

- Heater indicator will glow when heater is ON.

- The temperature controller cum indicator should be set on the temperature that needs to be controlled. This can be done by switching the push switch of the temperature controller knob and rotating it in the direction needed. Now release the push switch the temperature controller that is responsible for temperature control in the chamber will now switch to the chamber to indicate the actual temperature.

- After the desired temperature is attained, allow it to become stable for about half an hour. Now it is ready for use/ loading.

- After the work is over switch it OFF.

Precautions:

- Operate the incubator only with 230+10V Volts, Single phase 50 Hz, AC supply.

- Protect the incubator from direct sun rays or draughts especially while in use.

- While loading and unloading be careful and avoid touching the block, as it is hot.

- The incubator surroundings should be clear of any loose paper, clothes, etc.

Maintenance:

- Paste the sticker on instrument ie. UNDER MAINTENANCE.

- Inform to Maintenance Department.

- If necessary, call to service engineer of instrument manufacturer for maintenance activity.

- Check for any loose connections.

- After maintenance activity, make a maintenance record.

- Remove sticker i.e. UNDER MAINTENANCE.

- Now Dry Bath Incubator is ready for use.

Records:

- Machine Maintenance Plan

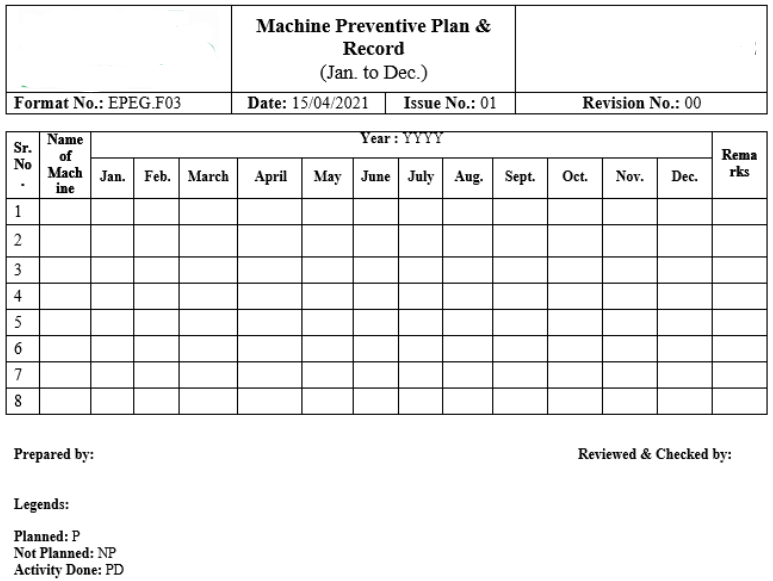

- Machine Preventive Maintenance plan

- Machine Preventive Maintenance record

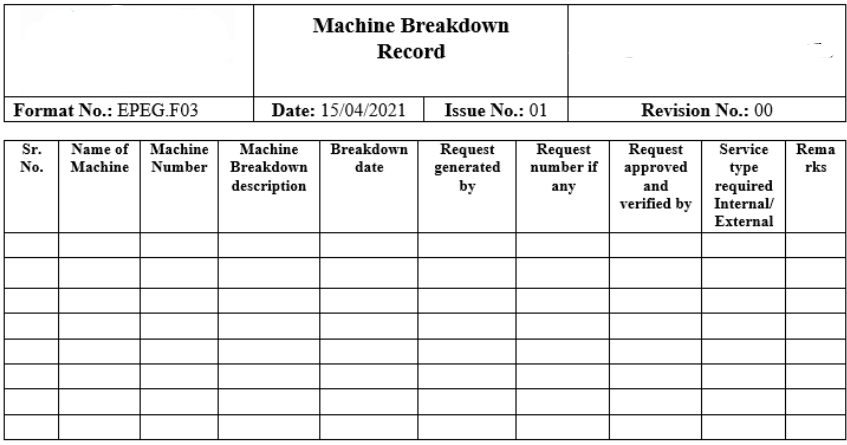

- Machine Breakdown Record

- Calibration Plan

- Machine Cleaning Record

Calibration:

- Minimum once in year

Distribution:

- Management representative

- Department head

- Microbiologist

- Maintenance head

Similar SOPs:

- SOP for Cleaning and Operation of Outside Micrometer

- SOP for Monitoring and Recording Critical Environmental Parameters of Different classes

- SOP for Microbiological Testing of In-Process Packing Material (Bioburden Test)

- SOP for Operating and Validating Anaerobic Systems

- SOP for Operating and Validating a Biosafety Cabinet

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].