1.0 Objective: To lay down the procedure for the cleaning, Operation of Labeling machine.

2.0 Scope: This procedure is applicable to the cleaning, operation of Labeling machine in liquid packing section.

3.0 Responsibility: Production Officer, Production Incharge to follow this SOP

Head of Department for overall compliance to this SOP.

4.0 Cleaning

4.1 General Points:

4.1.1 Stop the machine by pressing the red push button, and displace the acrylic cover from its closed position towards the opposite side.

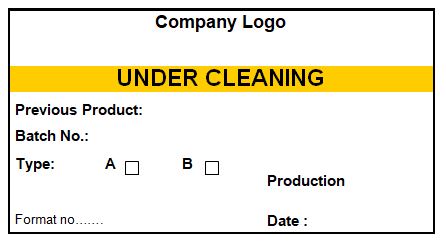

4.1.2 Affix the “UNDER CLEANED” label on the machine as per Annexure – I.

4.1.3 Stop the vacuum pump, and switch the “OFF” actuator on the switch panel.

4.1.4 Put “OFF” the main switch in the cabinet. The red pilot lamp goes off. Remove the labels from the labeling machine.

4.1.5 Remove the glue pot, glue cylinder, and rubber roller. Wash them with water. Scrub the roller with any hard material, and wipe the roller only with a soft cloth.

4.1.6 Wipe the strip belts with a moist cloth. Remove the stereo from the stereo holder.

4.1.8 Clean the steel and rubber rollers with water and wipe them dry.

4.1.9 Clean the vacuum holes of the pickup cylinder. If necessary, clean the holes with a thin wire for an effective vacuum.

4.1.10 Steel parts may be cleaned with 70% isopropyl alcohol.

5.0 Procedure:

5.1 General Point:

5.1.1 The direction of the machine operation is in clockwise direction as indicated by the arrow on the hand wheel on top of the machine.

5.1.2 The speed of the machine is adjusted by turning a small hand wheel on the right-hand side in a clockwise direction. The speed can be varied from 60 to 150 bottles/minute.

5.1.3 The machine can be used for bottles having diameters ranging from 20 to 70 mm in the vertical direction.

Related SOP: Operation of vials Labeling machine

5.2 Operation:

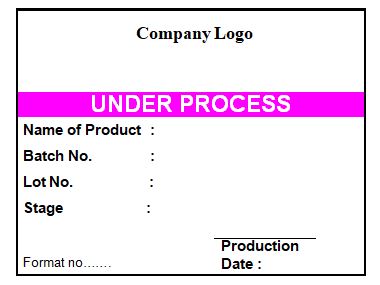

5.2.1 Affix the “Under process” label on the machine as per Annexure – I.

5.2.2 Add the ready to use gum paste into the glue – pot till at least half its volume.

5.2.3 Place the rubber roller on the mount provided near the pickup drum taking care the screw is inserted in the slot provided on the drum. Lightly dampen the roller with water and turn it anti–clockwise till it stops.

5.2.4 Regulate glue application by means of adjusting the screw.

5.2.5 Pile up the labels and place them in the label box, the printed portion of the labels facing the operator. Readjust the level by means of adjusting the screws and upper plate screws provided.

5.2.6 Allow the filled and inspected bottles to come from the turntable onto the infeed conveyor and lock the transfer of bottles by turning the lock anti–clockwise. Ensure that the bottles are dry and clean on the outer surface. If not arrange to wipe and dry them externally.

5.2.7 For the overprinting of labels, insert the printing holder and tighten its screw. Fix the stereo by means of suitable tape on the printing holder. Turn the hand wheel till it faces the rubber roller. Apply printing ink on the steel roller by means of a brush and continue turning the hand wheel to get an impression of the overprinting on the label. Check for its correctness and proper placement on the label and also clarity. For finer adjustment, adjust with the help of the micro-screw provided.

5.2.8 Turn the main switch to the “ON” position and lock the acrylic cover above in its closed position. The red pilot lamp lights up on the push button station box.

5.2.9 Start the vacuum by turning on the actuator.

5.2.10 Press the inching button and adjust the amount of gum required on the roller by the lock nut screw arrangement provided on the gum holder.

5.2.11 Release the lock on the conveyor and continue to inch to confirm the machine setting is right.

5.2.12 Finally press the push button at the push button station for continuous operation.

5.2.13 For stopping the machine, press the red switch on the push button station boxes.

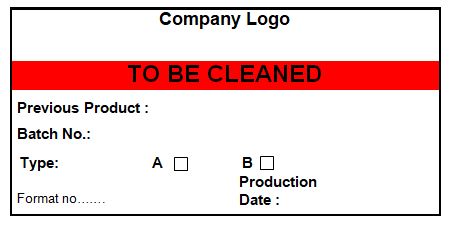

5.3 Affix the “TO BE CLEANED” label on the machine as per Annexure – I.

6.0 Abbreviations:

Nil.

Annexure-1

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].