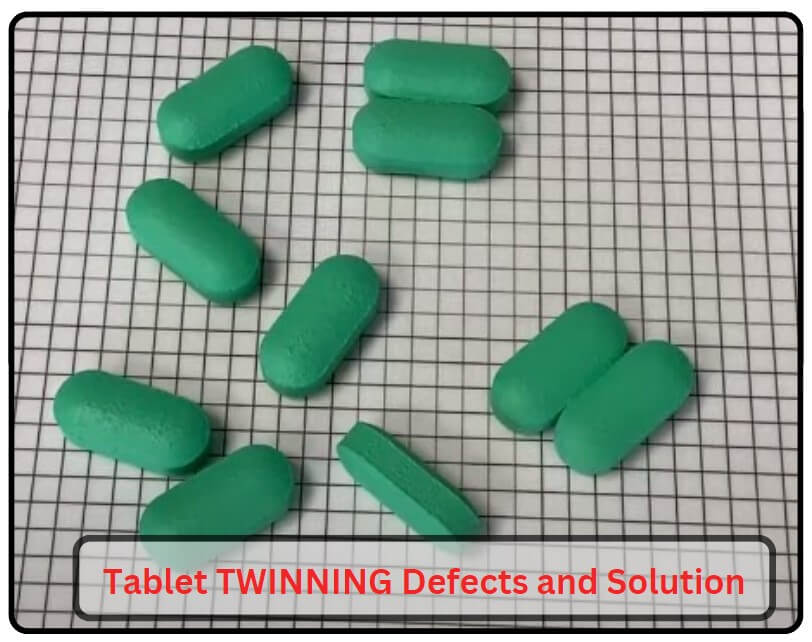

In pharmaceutical manufacturing, coating tablets requires careful attention to detail to prevent issues like tablet twinning. Twinning is common with capsule-shaped tablets, where two tablets stick together, resembling conjoined twins. This discussion focuses on tablet coating specialists and quality control experts, explaining the causes and solutions for tablet twinning.

Tablet Twining: Understanding the Defect

When capsule-shaped tablets stick together during the coating process, it’s called twinning. This can affect the evenness of the coating and how well the drug works. To address this issue, we need to make strategic adjustments while keeping the tablets intact and effective.

Related: Tablet Coating Problems and Remedies

Technical Solutions for Overcoming Twinning

To prevent tablet twinning, we need to consider design and process optimizations. Here are some solutions:

Tablet Design: Choose tablets with less flat surface to reduce contact areas. Capsule-shaped designs can be curved along the edges to lower the chance of twinning.

Coating Formulation: The type of coating used is important. Avoid formulations that make the tablet sticky. Add substances that reduce stickiness.

Solvent Drying: The rate at which the solvent evaporates is crucial. Poor drying can lead to over-wetting and twinning. Solutions include increasing the air temperature, reducing the spray rate, and adjusting the distance between spray guns and the tablet bed.

Spray Dynamics: Find the right balance between spray rate and droplet size. Too much spray can cause over-wetting, while large droplets due to low air pressure can slow down drying.

Pan Speed: The speed at which the coating pan rotates affects tablet contact time. To ensure that tablets are not exposed to too much moisture and are properly dried, you should adjust the pan speed to an appropriate level. This will help prevent any unwanted damage to your tablets during the drying process.

Spray gun distance: If the distance between the spray guns and the tablet bed is too short, there is a risk that the tablets will become over-wetted. When tablets are over-wetted and not given adequate time to dry, they are prone to stick together, resulting in twinning.

Proactive Measures to Perfect Spray Gun Distance:

- Increasing Distance: One solution is to increase the distance between the spray guns and the tablet bed. This allows for a more even distribution of the coating substance and ensures that tablets have sufficient space to dry before coming into contact with one another.

- Temperature Regulation: Alongside adjusting the spray gun distance, it’s advantageous to increase the tablet bed temperature. We can achieve this by increasing the inlet air temperature, which will enhance the drying process and reduce the risk of twinning caused by excessive moisture. This is because higher temperatures allow for faster evaporation of water from the surface of materials, making them less prone to twinning.

Implementing these strategies can significantly reduce the occurrence of tablet twinning, ensuring that the coating process remains efficient and maintains the quality of the pharmaceutical product.

Quality Control for Tablet Twining

Quality control is important for identifying and preventing tablet twinning. Here are some steps you can take:

- After applying the coating, expert technicians should visually inspect the tablets for signs of twinning, like tablets sticking together or uneven coating.

Conclusion

Preventing tablet twinning requires careful consideration of spray application and drying. By fine-tuning spray dynamics, pan speeds, and tablet design, we can eliminate twinning defects. Let’s work towards defect-free tablet coatings by harmonizing technical parameters. Together, we can ensure the delivery of safe and effective medications.

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].