Learn about Temperature Mapping of Storage Areas their Objective, Frequency, methodology, protocol, significance, Procedure, and Guidelines.

Definition and significance: Definition: temperature mapping is a study in which it is ensured that the environmental condition of the studied area is uniform and well within the acceptance criteria

Objectives:

The objective of Temperature Mapping is to provide clear guidance on how to conduct a temperature mapping study in a temperature-controlled storage area. This guidance applies to any space designed for the storage of TTSPPs or other temperature-sensitive products.

Why Temperature Mapping is Important?

Temperature mapping is a study in which it is ensured that the environmental conditions of the studied area are uniform and well within the acceptance criteria.

Frequency:

The Frequency of Temperature Mapping shall be followed as:

- Subsequent mapping activities must also be carried out periodically – every three years.

- Whenever big changes happen within the area/ store.

- Whenever an analysis of temperature or humidity monitoring records shows unexplained variability outside normal operating limits.

Procedural Guidelines:

A temperature mapping process involves 4-stages as given below:

- Prepare a mapping protocol.

- Carry out the mapping exercise (Methodology).

- Prepare a mapping report.

- Implement the recommendations by carrying out the remedial and other actions identified in the mapping report.

Procedure for Temperature Mapping of Storage Areas:

- All the controlled storage areas shall be considered for temperature mapping.

- Temperature mapping shall be done in the warmest and coolest seasons for yearly variation.

- Temperature logging duration shall be between 5 to 15 minutes.

- For storage areas temperature mapping shall be done for 7 to 10 consecutive days.

- The mapping of stability chambers and walkin chambers shall be done for 24 to 72 hours.

- Cold storage and freeze mapping shall be done for 24 to 72 hours.

- Studies like door opening, and power failure shall be included in the temperature mapping.

- Worst-case locations shall be determined so that they can be used for routine monitoring.

Significance:

The Signification of Temperature Mapping is as follows:

- Ensure the temperature of the storage area is within limit & uniform.

- To ensure RH of the storage area is within limit & uniform.

- To ensure correct storage conditions for cold chain products.

Preparation of a Temperature Mapping protocol:

- Approval page and change control history

- Glossary

- Description

- Scope

- Objectives

- Methodology

- Mapping report

- Annexes as needed, including templates for the mapping report

Methodology:

STEP 1- Select EDLMs: NIST

STEP 2- Designate the mapping team

STEP 3- Survey the site

STEP 4- Establish acceptance criteria

STEP 5- Determine EDLM locations, record, and fix

STEP 6- Conduct the mapping activity

STEP 7- Download and consolidate the data

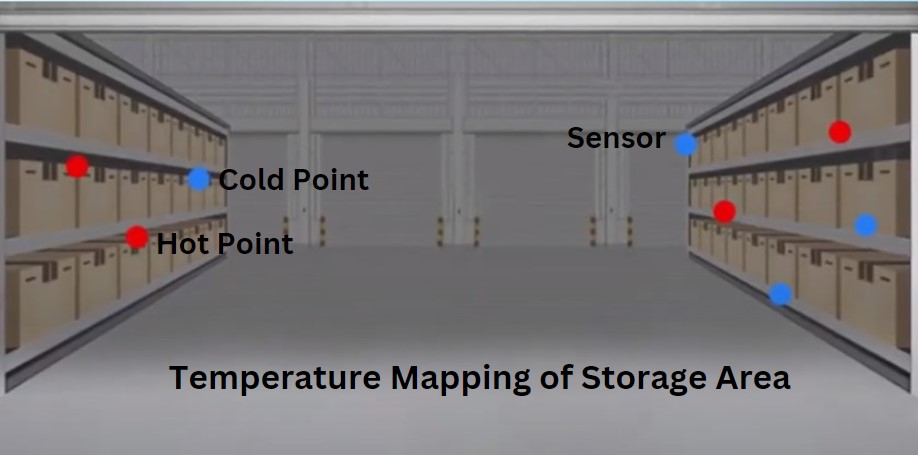

Temperature sensors:

The usage details of the temperature sensor for Temperature Mapping are as follows:

- Appropriate temperature ranges (-30 to +60 DC).

- The memory shall be sufficient.

- 3 points of calibration shall be done.

- The accuracy of temperature sensors shall be ±0.5DC.

Selection of EDLM and Time

- Length and width: EDML locations every 5-10 meters.

- Height: If the ceiling height is 3.6 meters or less, position EDLMs directly above one another at high and low levels (1.2 meters and one EDLM at 3.0 meters.

- The ceiling height is greater than 3.6 meters.

- At 1.8 meter

- At 3.6 meter

- At 5.4 meter

Analyzing the data and preparing the mapping report:

- Analyze the overall temperature stability of the study area and identify the variations that occur.

- Minimum and maximum temperatures.

- Hot and cold spots.

- Interpreting the results and making recommendations.

Conclusion

Temperature mapping is super important in making sure everything stays just right in different industries. It’s all about checking and understanding how hot or cold things are in different spots. This helps companies spot any possible issues, fix them up, and make sure the products stay top-notch and follow the rules.

By planning how to check, collecting info, and keeping an eye on things, temperature mapping helps understand how temperatures change and lets companies fix problems before they happen. Following the best ways to do things, writing down what they find, and fixing any issues helps companies follow the rules, avoid problems, and keep getting better at controlling temperatures.

This whole temperature mapping thing is a big deal for keeping products safe, making sure they’re good quality, and meeting the standards set by different industries like medicines, food, health stuff, and shipping.

References:

- USP 1079: Good Storage & Shipping Practices.

- USP 1118: Monitoring Devices — Time, Temperature and Humidity.

- 21 CFR part 11: US Food & Drug Administration (FDA).

- WHO Technical Supplement. Calibration of temperature control and monitoring devices.

- WHO Technical Supplement. Qualification of temperature-controlled storage areas.

FAQs

Over the range of sensors, it needs to be calibrated on 3 points, which are minimum, optimum, and maximum of sensors.

Flexible sensors with electronic displays can be used

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].