Edge Runner Mill is widely used in industries till now, if talk about its usage centuries ago, the manual mortar and pestle was the traditional tool for accomplishing size reduction, and it is still frequently used on a modest basis. Compression size reduction may also be done on a small scale with end-runner mills and edge-runner mills, which are mechanical versions of mortar and pestle compression comminution.

Edge Runner Mill Principle

Edge Runner Mill principle works on the crushing (Compression).

Construction

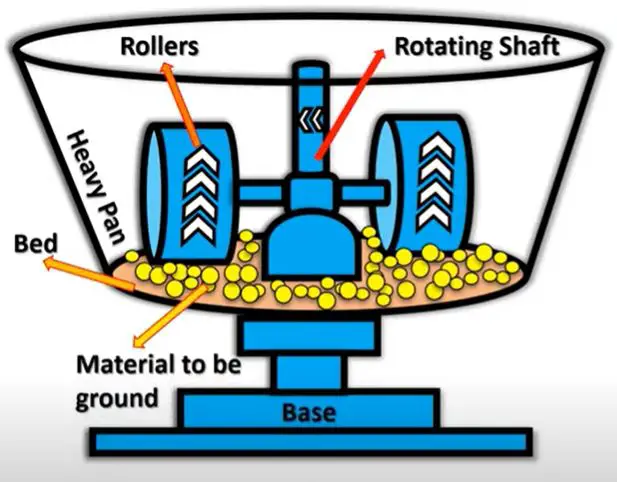

It consists of two heavy-weight rollers attached with the help of a shaft.

The roller moves on a bad which is made of stone or graphite and these rollers and bad are joined with a base which gives support to it.

Edge Runner Mill Working

- First of all, put the materials on the bed with the help of a scrapper.

- Start the roller and materials soon start to crush while the roller moves on it.

- The stones rotate on their axis while traveling around the shallow stone bed. The outer component of the wheel must travel a long distance to obtain size reduction by shearing, as does the inner, through crushing. The material is ground for a set amount of time. The powder is collected and sieved to get powder of the desired size.

- At last crushed powder is collected and separated out through a sieve.

Usage:

- Runner Mill is used to grinding hard materials to get fine particles.

- The mill is also used for plant-based products.

Merits

- Easy to use.

- It is free to move without any attention.

- East to clean and required less space to install.

Demerits

- As it is not much compact so chances of contamination are high.

- No use for sticky materials

- If compared to others mills like hummer and Ball mill, it required more space to install.

- Edge Runner Mill required more time to get results and energy consumption is also high.

- The noise level is high

Cost:

It costs around $350-500 for 150 to 170 kg (made of stainless steel). check the latest price here