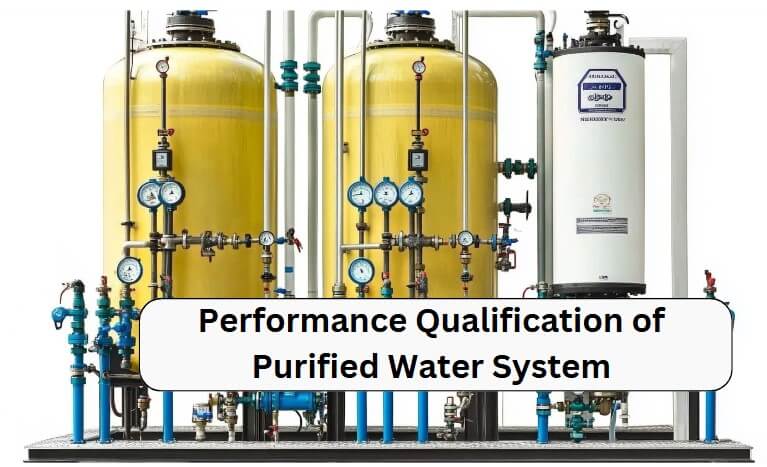

Performance Qualification of Purified Water System

In a pharmaceutical company, we often need to conduct Performance Qualification. While performing Performance Qualification, we have to pay attention to many aspects, such as following and implementing each step of the process according to the protocol. Therefore, you can review each process and its steps listed below, which should be included in a protocol. … Read more