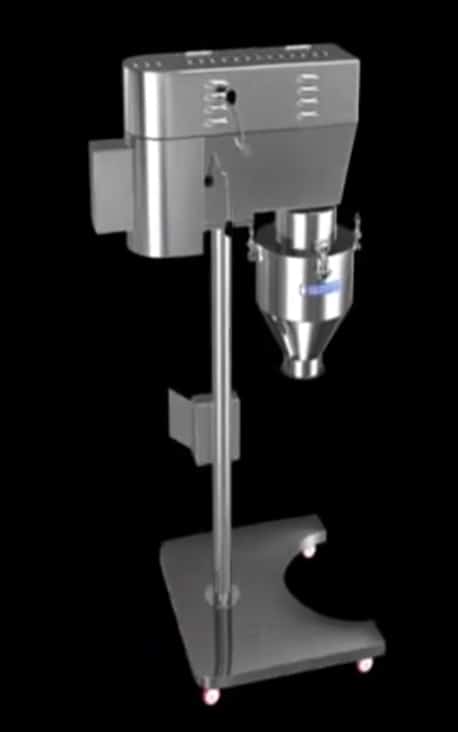

Multimill is used widely in pharmaceuticals (granulation section), cosmetics, chemicals, and bulk drugs for cutting granules into small particle sizes by using cutting, Pulverization, and hammering mechanisms.

Components of multi-mill:

1. Hopper inlet

The hopper is used to feed products to the mill.

2. Milling chamber

The milling chamber contains a screen to reduce particle size, and twelve milling and cutting edge blades and two scraper blades are responsible for milling.

3. Discharge point (chute)

These components are used for the collection of milled products.

4. Mechanical chamber and electrical chamber

This section is used to install all mechanical components like Gear, motor, moving belts, and electrical components like wiring, switches, and MCVs.

Principle and Mechanism of Multimill:

The principle involves variable force, rotating blades having both knife and sharp edges with validated screen size to reduce particles in a controlled manner. The mechanism involves the pulverization process (Pulverization is the grinding and crushing of materials into small particles). knife blades are used to cut the large particles into small size particles, that are generated during the FBD drying process. The hummer process is also used to break large particles into small sizes.

Speed Ranges of Multimill:

Multimill has a wide range of options for speeds to run. It can be operated from 720 to 2880 RPM (also depending on the make).

Related Post: Fluidized bed dryer

Features of Multimill:

- All parts of the mill are made of S.S. 304/ S.S. 316 grade.

- Product contact parts are easy to dismantle and clean.

- Blades and scrapers are made of hard materials and plated with hard chrome.

- It can be run for a long time continuously.

- Usage of the cylindrical drum for more output.

Multimill Application:

- Multi mills can be used for a variety of functions such as wet and dry granulation, pulverization

- The multi-mill unit is useful in pharmaceuticals, cosmetics, dyes, paints, food products, herbs, detergents, pesticides, polymers & resins, and fertilizers.

Advantages and Disadvantages of Multimill:

Advantage:

- It can be used for milled wet materials.

- Easy for operational activity.

- Variable speed options are also available.

- Easy to dismantle and clean.

- Required less space to install.

Disadvantage:

- It causes more noise.

- Chance of an accident on changes the speed frequently.

Price:

Stainless steel Multi Mill price ranges from $900 to $1400.

Related Post: Rapid mixture granulator

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].