FBD refers to a Fluidized bed dryer that is commonly used in the pharmaceutical industry to reduce the moisture content of pharmaceutical granules. It is the best technique used by the manufacturer to produce a good quality product. However, with time, new advanced techniques are introduced to replace old like; in case of FBD, a new version has been introduced that is called FBP.

Principle

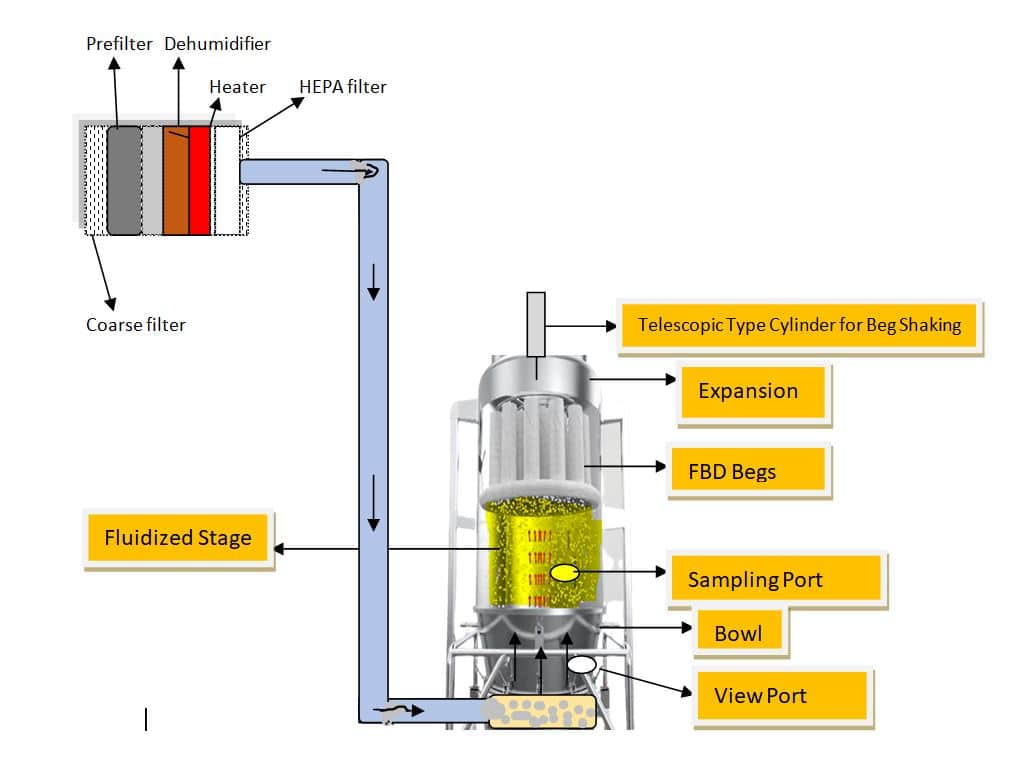

FBD works on the fluidization principle. A high-pressure Hot air from the supply is passed through the perforated container containing wet granules. As the hot air passes through container granules start to suspend in the air to become dry (called a fluidized state), the process is called fluidization.

(FBD) Diagram

Components of Fluidized-bed Dryer

- Body Stainless steel

- Inlets Filters

- Air preparatory unit.

- Product container or Bowl.

- Expansion chamber

- Exhaust filter.

- Exhaust blower.

- Control panel (MMI).

- Air distribution plate.

- FBD bags (Finger Bags)

- Plenum

- Gaskets

Working of Fluidized bed dryer

A fluidized bed dryer works by passing Hot air with high pressure through a perforated bed of moist solid particles. The hot air passes at a velocity greater than the settling velocity of the particles resulting, particles starting to suspend in the air. As the moist particle suspends in hot air, the moisture content of solid particles reduces to achieve the desired loss on drying (LOD). The drying vapors carry the vaporized liquid away from the moist solid particles. In some cases, the leaving gas is recycled to conserve energy.

Advantages of FBD

- If the gas-particle constant is excellent, it can lead to efficient heat and mass transfer rates, which results in faster removal of moisture.

- If part of the thermal energy for drying is supplied by the internal heat exchanger, high thermal efficiency is usually achieved.

- Lower initial and ongoing costs.

- Drying contact time is reduced.

- Stability and easy to control.

Disadvantages of FBD

- Considerable pressure drops are caused by the necessity to suspend the entire bed in gas, resulting in high energy usage.

- Increased gas handling is required due to substantial exhaust gas recirculation for high thermal efficiency operation.

- Inadequate fluidization and flexibility, particularly if the feed is overly wet.

- In case of organic solvents to eliminated by drying, this is not the best equipment to use.

- For certain types of fluidized bed dryers, product quality is non-uniform.

- There is a high risk of attrition and, in some situations, the fine particle becomes aggregate.

- When processing poisonous or flammable substances, traditional hot air fluidized bed dryers are not a good solution since there is a risk of fire or explosion if flammability limitations are exceeded.

Troubleshooting In FBD and Remedies:

Accidental Blast in FBD: Sometimes FBD outlets filter may clog. so it may create high pressure inside the chamber.

Remedies: Clean the filter as per the given frequency or during batch changeover cleaning. check the pressure gradient in the manometer or alarm during the process.

FBD Broken Begs: Sometimes begs may break leading to powder flow outside from the duct.

Remedies: To overcome this problem Solid flow monitor (SFM) Test is to be conducted as per frequency.

Electrostatic charge: Electrostatic charge can sometimes build up, which can cause powder to ignite or burn.

Remedies: Do the proper earthing of equipment in use.

FAQs on Fluidized bed dryer

The endpoint in FBD is calculated by using Loss on drying Method.

The full form of FBD is (Fluid Bed Dryer)

FBD is used for only drying and, FBP is used for Granulation, Drying, Agglomeration, and Coating Processes.

FBP stands for Fluid bed processor

Preheating of granules is done to prevent the granules from adhering to the bowl.

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].

nice explanation about FBD machine

thanks

Nice Explanation about FBD

Thankyou sir