Standard Operating Procedure (SOP) for Operation and Calibration of Heating Block

1.0 Objective: The objective of this Standard Operating Procedure is to lay down the procedure for operating and calibrating the Heating Block.

2.0 Scope: This SOP covers the operation and calibration of the Heating Block in the microbiology Lab.

3.0 Responsibility: Microbiologist: Responsible for implementation of this SOP

QA Officer/QAM: Responsible for Overall compliance with this SOP.

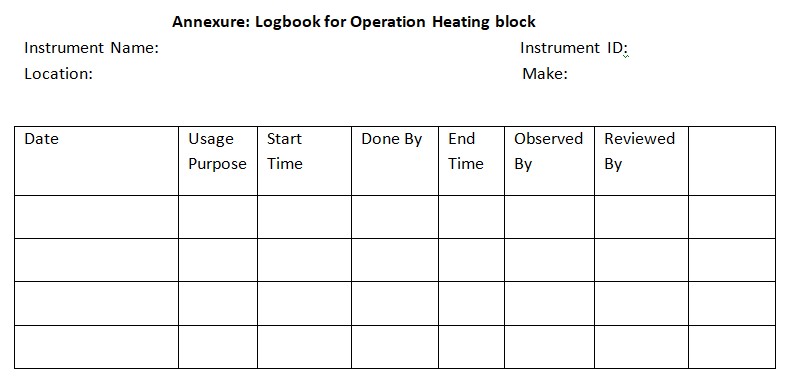

4.0 Procedure:

4.1 Operation:

4.1.1 Ensure that the instrument is visibly clean and free from dust.

4.1.2 Switch ‘ON’ the mains switch. Turn on the power switch of the instrument and observe that the LED of the Temperature indicator displays the ambient value.

4.1.3 Press the ‘SET TEMP.’ key (Red Button) to pre-set the desired performance parameter.

4.1.4 The LED shall display the last setting. Turn the setting knob clockwise to decrement until the LED displays the desired set value. Use the second knob for fine setting if required. Depress (Release) the SET key.

4.1.5 The LED shall return to display the ambient value of the chamber.

4.1.6 The unit will automatically work to attain the set temperature with the on-and-off cycling of the heater.

4.1.7 The heater selection (heater capacity) switch is provided with positions 37°, 45°, and 75° or higher.

4.1.8 Initially, select the switch at HIGH to quickly reach the set point.

4.1.9 Turn it to LOW when the display is close to the set point for fine and accurate control, preventing the temperature from exceeding the set value.

4.1.10 Choose the LOW position when the set point is nearing ambient for accurate and precise performance.

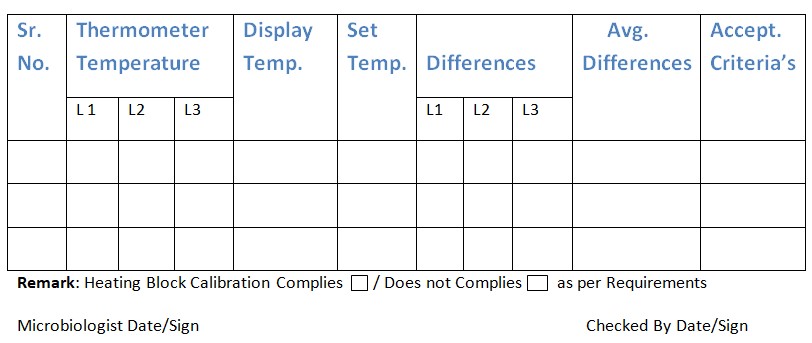

5.0 Calibration:

5.1 Operate the instrument as per the above procedure.

5.2 Set the temperature knob to the desired temperature for calibration. Generally, it is kept at 37°C.

5.3 Place a calibrated thermometer with an appropriate range in the chamber of the heating block at different Locations.

5.4 Set three different temperatures and record the results continuously for 60 minutes at 15-minute intervals.

5.5 Note down the temperatures in the calibration format.

Acceptance Criteria: Deviation of ± 1.0°C from the Set Temperature.

Frequency: Calibration Frequency: Yearly ±30 Days

Related: SOP for Hot Air Oven

6.0 Maintenance:

6.1 Clean the instrument with a dry cloth.

7.0 Abbreviations:

SOP: Standard Operating Procedure

LED: Light Emitting Diode

QA: Quality Assurance

QAM: Quality Assurance Manager

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].