1.0 Objective: To lay down the procedure for Calibration of Dipstick.

2.0 Scope: This procedure is applicable for the Calibration of Dipstick in the Liquid Oral department.

3.0 Responsibility: Production Officer, Production Executive.

4.0 Procedure:

4.1 Take a Plastic bin having about 70 liters capacity and tare it on a suitable calibrated balance.

4.2 Fill purified water at 25°C in the bin to weigh exactly 50 Kg ± 0.1 Kg, so that the net volume is 50 liters.

4.3 Mark the water level on the bin (50 liters mark).

4.4 Transfer the content of the bin to the respective tank.

4.5 Refill the bin with purified water up to the 50 liters mark and transfer it to the tank.

4.6 Repeat the filling till the minimum level assigned for the tank is reached.

• For tank number 1: 200 liters.

• For tank number 2: 500 liters.

• For tank number 3: 500 liters.

4.7 Put the respective dipstick through the manhole provided in the tank.

4.8 Mark the minimum level on the dipstick.

4.9 Repeat the filling of the tank with the specified increment of volume for tank number 1 (100 liters), and tank number 2 & 3 (200 liters).

4.10 Mark the level after completing each increment till the highest capacity of the tank is achieved.

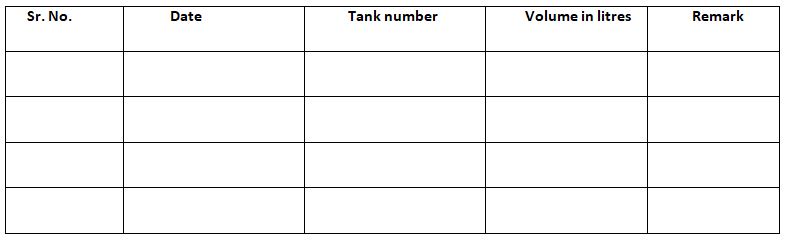

4.11 Fill in the details as per Annexure-1

Related: Storage of change parts for Liquid oral

4.11 Frequency: Once a year.

5.0 Annexures:

Annexure-1

6.0 Abbreviations:

Nil.

Annexure-1 Calibration of Dipstick

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].