A Venturi meter is used to measure the rate of flow of liquid (speed, and velocity) in a pipe. Here we will discuss about Venturi flow meter Principle, Flow diagram, construction, Working, advantages, Disadvantages, and Principle.

Principle of Venturi Flow Meter:

Venturi Flow meter is based on the principle of Bernoulli’s theorem.

It consists of two tapered sections in the pipeline with a gradual constriction (throat) at its center. When fluid is passed through the venturi meter, there are changes in the pressure head (ΔH) and an increase in the velocity due to the constriction of the venturi meter, (as per the Bernoulli). The velocity of the fluid is easily measured by the formula given below:

Uv=v √2g. ΔH

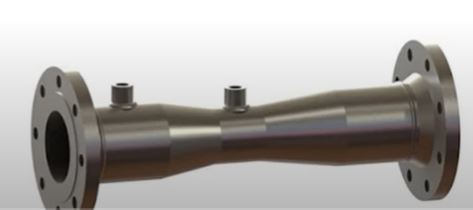

Construction of Venturi meter:

- It consists of two tapered sections and is inserted in a pipeline with constriction at the meter’s center.

- The upstream cone is normally shorter than the downstream.

- The tapers are smooth and gradual

- A manometer is connected at points A and B to measure the pressure difference.

Working of Venturi Meter:

Now, Let under the Working of the Venturi Meter:

First venturi meter is inserted between the pipeline. When fluid is passed through the venturi meter, the velocity of the fluid is increased at the throat, due to the constriction, As a result of decreased pressure in the upstream core (or change in the pressure head) which is further calculated through a manometer. the calculating formula is:

Uv=Cv √2g. ΔH

- Uv= is the velocity of the fluid through the venturi meter.

- Cv= Co-efficient of the venturi meter.

- ΔH= Pressure Head Difference.

Now, find out the velocity of the fluid by putting the value of ΔH (which is measured in a manometer) in this equation.

Advantages:

- Lower probability of being clogged with sediment.

- High discharge coefficient.

- Its actions are entirely predictable.

- Installable in a vertical, horizontal, or inclined position.

- Low-pressure drop (10% of p or less).

- Less susceptible to damage.

- Much better suited to gas flows with entrained liquid.

- Comprehensive guidelines (ISO 5167).

Disadvantages

- Because of their size, they cannot be used in places with the limited size of space.

- The initial investment, installation, and maintenance costs are high.

- long laying length is necessary for the venturi meter to function properly, a straight pipe free of fittings and misalignments must come before it in order to prevent flow turbulence.

- Higher manufacturing costs.

- Enables the measurement of high flow rates in pipelines with a few-meter diameter.

- Due to the high-velocity fluid passing the pressure tapping at the throat, high Reynolds number gas flows are more susceptible to “tapping errors.”

Related: Hammer Mill

Usage/ Applications of Venturi meter

- It is commonly used for liquid (water) and also for gases.

- Wherever high-pressure recovery is necessary, it is used.

- Can be used to measure the flow rates of liquids that are filthy, gaseous, suspended, and water.

References:

- Pharmaceutical engineering books by CVS Subrahmanyam

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].