The pharmaceutical industry generates lots of wastewater during the production or formulation of medicines. So it is very important to treats this wastewater by using various techniques. Water purification technology is used to eliminate solids from liquids. The impure solids can be coarse, suspended, colloidal, and dissolved. In the purification process, they need to be removed in descending order through a chain treatment.

Collection of Wastewater:

It is recommended to Collect the wastewater using a closed pipeline or by directing the gutter wastewater towards the ETP side. In an open gutter, additional pollutants such as algae, vegetation, soil, leaves, papers, and plastic may enter the effluent plant. The velocity in the closed pipe should be maintained between 2.5 to 3.5 feet/second, and in the case of an open gutter, it should be between 2.5 to 8 feet/second. This prevents solids from settling out and ensures they are pushed forward.

Maintaining the velocity is a important part; it should not be too high. In the open gutter, it should not exceed 6 to 7 feet per second, and in a closed pipeline, it should not exceed 8 feet per second. A slope should be provided every 50 meters for cleaning gutters and pipelines.

Read Also: Pharmaceutical AHU and HVAC Components

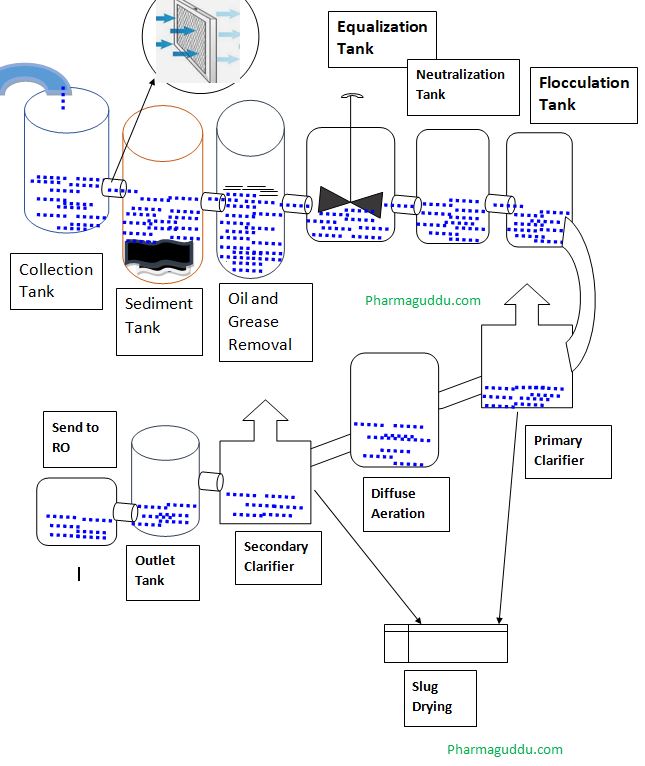

Stages involve in Effluent Treatment Plant (ETP)

- Screen for ETP

- Grit chamber

- Oil grease Trap

- Equalization Tank

- Neutralization Tank

- Primary Clarifier

- Flocculation Tank

- Anaerobic Lagoons

- Aeration Tank

- Secondary Settling

- Sludge Drying bed

- Oxidation Pond

- Chlorination Tank

- Gardening

1. Screen for ETP:

The screen should be adjusted at an angle of 45 to 60 degrees to the vertical if needed. The screen should be positioned at a right angle to the direction of flow. The screen is used to eliminate large particles, cloth, and plastic; the screen size used is 10 mm.

2. Grit chamber:

Grit is an inorganic pollutant and inert in nature, heavier in weight, and easily and quickly settable class.

3. Oil grease Trap:

It is necessary to clean the oil or grease that comes from lubrication, boiler, cooling tower, and blowdown of the boiler. T-Pipe and gutter are used to prevent floating grease or oil. After that, it is necessary to remove the top layer of the water and collect it in the waste drum. Then it should be sent for further disposal and treatment.

4. Equalization Tank:

At this stage Water is mixed for making the homogeneous mixture with the help of air or a stirrer in an equalization Tank to remove heterogeneity.

5. Neutralization Tank:

The neutralization tank is used to adjust the pH of effluent with the help of acid (HCL) for alkali (NaOH).

To balance 1 mg/liter of acidity, the chemical requirements in mg/liter are as follows: calcium carbonate 1.0, calcium oxide 0.56, calcium hydroxide 0.74, Sodium Hydroxide 0.8. Similarly, to neutralize 1 mg/liter of alkalinity, the chemical requirements in mg/liter are sulfuric acid 0.98, HCL 0.72, nitric acid 1.26, and carbonic acid 0.62. It is essential for water to be neutral before undergoing further treatment.

6. Primary Clarifier:

Primary Clarifier stage works on the gravitational force. In the wastewater treatment process, the solids are separated from the water in the primary sedimentation tank, also known as a settling tank or clarifier, using the force of gravity. This happens because the solid material that settles in this tank is present in the effluent right from the start. On the other hand, the biomass solid, formed through secondary biological activity later in the same ETP, is what settles in the secondary clarifier. It’s important to note that this biomass solid is not present in the initial stages.

Read Also: HEPA Filter uses in Pharmaceutical manufacturing

7. Flocculation Tank:

A flocculation tank is used in the Effluent treatment plant to dissolve the colloidal solid. These are solid, and their size falls between less than suspended solids and greater than dissolved solids.

Their size is less than one micron. They carry an electrical charge, preventing them from settling easily. Substances like alum, lime, FeSO4, and polyelectrolytes are employed to help these particles settle, forming clumps.

8. Anaerobic Lagoons:

Bacteria are needed for the treatment of effluent wastewater. These bacteria are classified into three categories aerobic, anaerobic, and facultative. Aerobic Bacteria need Oxygen for slow combustion. This Oxygen is taken from the water.

Anaerobic bacteria form the bond by decomposing carbonate sulfate, nitrate, and facultative. These classes can use either of the sources of oxygen and work in the presence or absence of oxygen. Anaerobic bacteria also need oxygen, but there is no need to fix aerators. They use urea, and superphosphate is limited due to the earlier embankment of the tank; it is termed a lagoon.

9. Aeration Tank:

Inside Aeration Tank, Aeration is provided to the tank with the help of aerator or agitator. This technique is important for trickling filters, oxidation ponds, aerated lagoons, activated sludge, bio-disc, and bio bulb.

10. Secondary Settling:

Once the completion of aeration, the micro-organism utilized the biological oxygen demand as a food and grow and multiplied; As a result, the Biomass began to show up as a block patch, and this flock got separated as sludge from the liquor. A problem arises if the Biomass stays mixed in the liquor. These access layers are taken out from the tank to the alternative sludge bed to dry the sludge and use it as soil for land filling. Maintain 20-30% sludge to water.

11. Sludge Drying bed:

Sludge settled in the clarifier is removed and It’s then dried and used for landfill.

12. Oxidation Pond:

This is a simple system for treating effluent and stabilizing the organic impurity. Here water is getting pure from the wastewater.

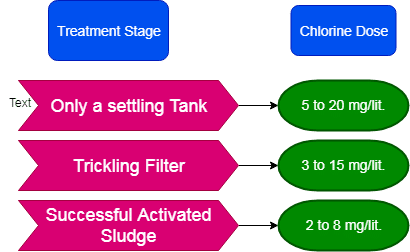

13. Chlorination Tank:

Chlorination is done to kill pathogens. Chlorine is also combined with many other chemicals like Ammonia, iron, manganese, sulfide, odor, and color production material. Chlorine helps in purification of water. The amount of chlorine added depends on the phase at which the wastewater has already been treated.

The resident chlorine should not be less than 0.5 mg per liter and not more than 1.0 mg per liter.

14. Gardening:

Gardening is the Utilization of treated pure water for gardening purposes after testing and release by QC.

Related: Types of water in pharmaceutical

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].