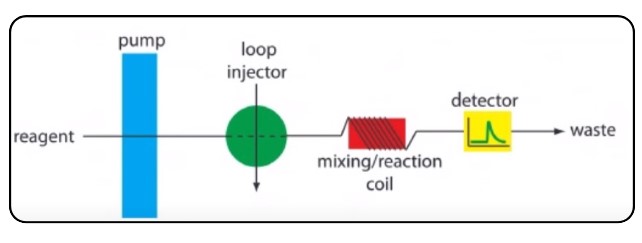

The instrument being discussed in this context is known as a Flow Injection Analyzer (FIA). Its primary function is to automate several processes typically associated with conventional wet chemistry procedures. Specifically, the Flow Injection Analysis is designed to perform tasks such as automatically picking up samples, mixing them with the required reagents, and subsequently detecting the outcomes.

Flow Injection Analysis Stages:

Detection Process

The detection process involves assessing the color produced during reactions, with the color intensity being directly proportional to the concentration of the substance in the solution.

Versatility of FIA

This functionality allows the instrument to be versatile, enabling the analysis of various substances, including chloride, nitrate, nitrite, phosphate, and ammonium.

To illustrate a specific analysis scenario, let’s delve into the example of analyzing orthophosphate in a Bray extract, a technique commonly used for estimating available phosphorus.

The setup for this analysis involves connecting the phosphate manifold, adjusting filters, incorporating a heater for color development, and modifying the sample loop and valve to suit the specific method.

Each substance targeted for analysis has its unique method, complete with specific reagents and detailed instructions on setting up the instrument accordingly.

Preparation of Standards and Reagents

Moving forward, the next critical step in the analysis process is ensuring that all the necessary standards and reagents are prepared.

Components for Orthophosphate Analysis

In the case of orthophosphate analysis, essential components include an ascorbic acid solution, a malate color reagent, a carrier (also referred to as a diluent), and the Bray extract containing the samples. Additionally, standards ranging from 0.5 to 20 parts per million phosphorus are required, along with a blank matrix solution.

Practical Aspect of Analysis

With all the components in place, the practical aspect of the analysis involves ensuring that the tubes connecting to the reagents are attached to the pump and that the entire system is primed with deionized water. After confirming a smooth flow, the lines are then switched to the actual reagents, including the carrier, color reagent, and ascorbic acid. This transition period typically requires a few minutes to allow the system to equilibrate.

Autosampler and Sample Running

Now that the instrument is set up, the autosampler can be loaded with both samples and standards. The actual process of running a sample involves observing the colored solution as it moves through the system, reacting with various reagents at specified points.

Detector and Results

The heart of the system, the detector (in this case, a spectrophotometer), measures the change in absorption as the solution passes through. The results of this measurement are then displayed on a computer screen in the form of peaks.

Analysis and Calibration

Each peak represents a different concentration of phosphorus in the standards. Analyzing the standard curve, which is essentially a graphical representation of the relationship between peak size and phosphorus concentration, allows for the establishment of a calibrated system. This calibrated system enables the quantification of unknown samples based on the size of their corresponding peaks.

Conclusion

In conclusion, Flow Injection Analysis (FIA) stands out as an automated and efficient method for analyzing various substances in a solution, with phosphates being a notable example. By streamlining the analysis process and minimizing manual intervention, FIA not only enhances efficiency but also reduces the likelihood of errors, providing researchers and analysts with reliable and accurate results.

Related Topics:

- How can I Prepare and Standardization 0.5 M Sulfuric acid

- 1.0 M Sulfuric Acid Solution- Preparation, Standardization, Reagents, Formula

- 0.1 M Sodium Hydroxide (NaOH), Preparation and Standardization

- Preparation and Standardization of 1 M Sodium Hydroxide Solution (NaOH)

- Preparation and Standardization of 1.0 M Hydrochloric Acid

- Quality Control Test for Secondary Packing Materials

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].