A tray dryer in the pharmaceutical industry is used to dry powders, granules, and other types of materials. It consists of a heated chamber with trays to place materials. The trays are usually stacked one on top of each other, and the drying process is usually done under controlled temperature and humidity conditions.

It is used on large scale in pharmaceutical, chemical, and cosmetic industries to achieve efficient material drying at low cost. Although it is an old method to dry, but it is still used in small and medium scales industries. Before installing, it must know about the tray drier principle, construction, and working.

Tray Dryer Principle

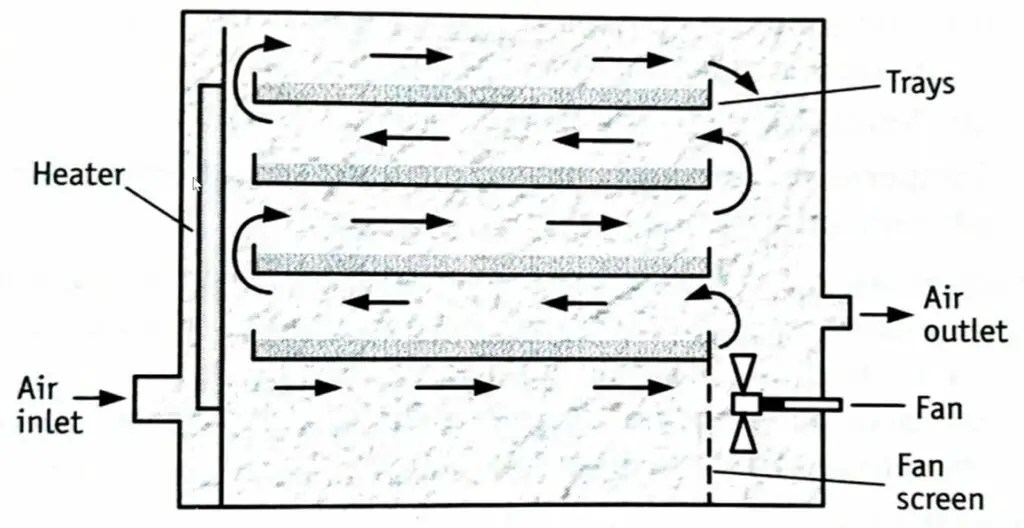

The principle of a tray dryer is based on the process of convection drying. Convection drying involves the use of hot air to remove moisture from the material being dried. The hot air is circulated throughout the drying chamber, and as it passes over the trays, it removes moisture from the materials on the trays. The temperature and humidity inside the chamber are controlled to ensure that the materials are dried at the appropriate rate. in short; hot air is continuously calculated inside the chamber, and forced convection heating takes place to remove moisture from the solid spread in trays.

Tray Dryer Construction

- The Tray Dryer design consists of a rectangular chamber whose walls are insulated.

- Trays are placed inside the heating chamber. the number of trays is rectangular or square and may vary with the size of the drier.

- Stainless steel tray Drier of laboratory size may contain a minimum of three trays, in industry size may contain a minimum of three trays, and in industry contain more than 20 trays.

- Trays are usually loaded from 10.0 to 100.0 millimeter deep.

- The dryer is fitted with a fan for circulating air over the trays. electrically heated elements are provided inside to heat the air. the thermal efficiency is improved using finned tubes.

- Air temperature is thermostatically controlled between 40 and 120 °C. The heat is controlled manually by setting the damper.

Related: Hummer Mill

Tray Dryer Working

- Wet solid is loaded into trays.

- Place the tray in the chamber.

- Fresh air is introduced through the inlet, which passes through the heaters and gets heated up.

- The hot air is circulated by means of fans at 2 to 5 m/s.

- The water is picked up by air.

- As the water evaporated from the surface, the water diffuses from the interior of the solid by capillary action.

- These events occur in a single pass of air.

- The time of contact is short and the amount of water picked up in a single pass is small.

- Moist air is discharged through the outlet. thus constant temperature and uniform airflow over the material can be maintained for achieving uniform drying.

Uses:

- Sticky materials, plastic substances, granular mass or crystalline materials, precipitates, and paste can be dried in a tray dryer.

- Drying crude drugs, Herbs, botanicals chemicals, powders, tablet granules, or parts of the equipment.

Advantage

- In try dryer, handling of materials (loading and unloading) can be done without losses

- Try the dryer is operated batch-wise

- Most efficient and consume less energy

- As it is available in different sizes with different price ranges, so its becomes easy to control capital cost

- It can be used on small scale as well as on a medium scale

- It reduces the drying time by removing moisture at an efficient rate.

- Easy to operate and handle

- Easy to installed

Disadvantage

- The tray dryer required more labor to load and unload hence the cost increase

- The process is time-consuming depending on the materials

- The dusty solids are not drier in a tray dryer

- It has limited capacity; so it can not use in a large-scale production

- Tray dryer has Limited scalability because Tray dryers are used only to dry low batch size at a time, which limits the scalability of the manufacturing process.

- It is not suitable for Thermolabile materials, liquids, and slurries.

Tray dryer uses in Pharmaceuticals

- A tray dryer provides a uniform drying process that prevents the materials from getting damaged, this is particularly important in the pharmaceutical industry since the material may be sensitive to heat.

- It is used to dry materials like; excipients, tablets, powder, and wet granules to dry.

- It is most efficient to dry for sticky materials

- Tray drier also used to dry equipment and glassware

- It is easy to clean and required less time in product-to-product changeover

Price

The tray dryer price for 60 kg is around 80k and 205k for 300 to 350 Kgs

Manufacturer

It is a design and manufacturer by tray drier mfg. companies; Some examples of tray dryer manufacturers include Bhagwati pharma, Bombaypharma, Acepharmamachines, etc.

Related: Ball mill

FAQs

Hot air is continuously calculated. inside the chamber, forced convection heating takes place to remove moisture from the solid spread in trays

A tray dryer is an equipment that uses hot air to remove moisture from the materials being dried whereas A vacuum tray dryer is under a vacuum. The drying chamber is sealed and a vacuum is created inside the chamber by using a vacuum pump. This causes the pressure inside the chamber to be lower than the atmospheric pressure outside.

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].